Propeller

A technology of propellers and blades, applied in the field of propellers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

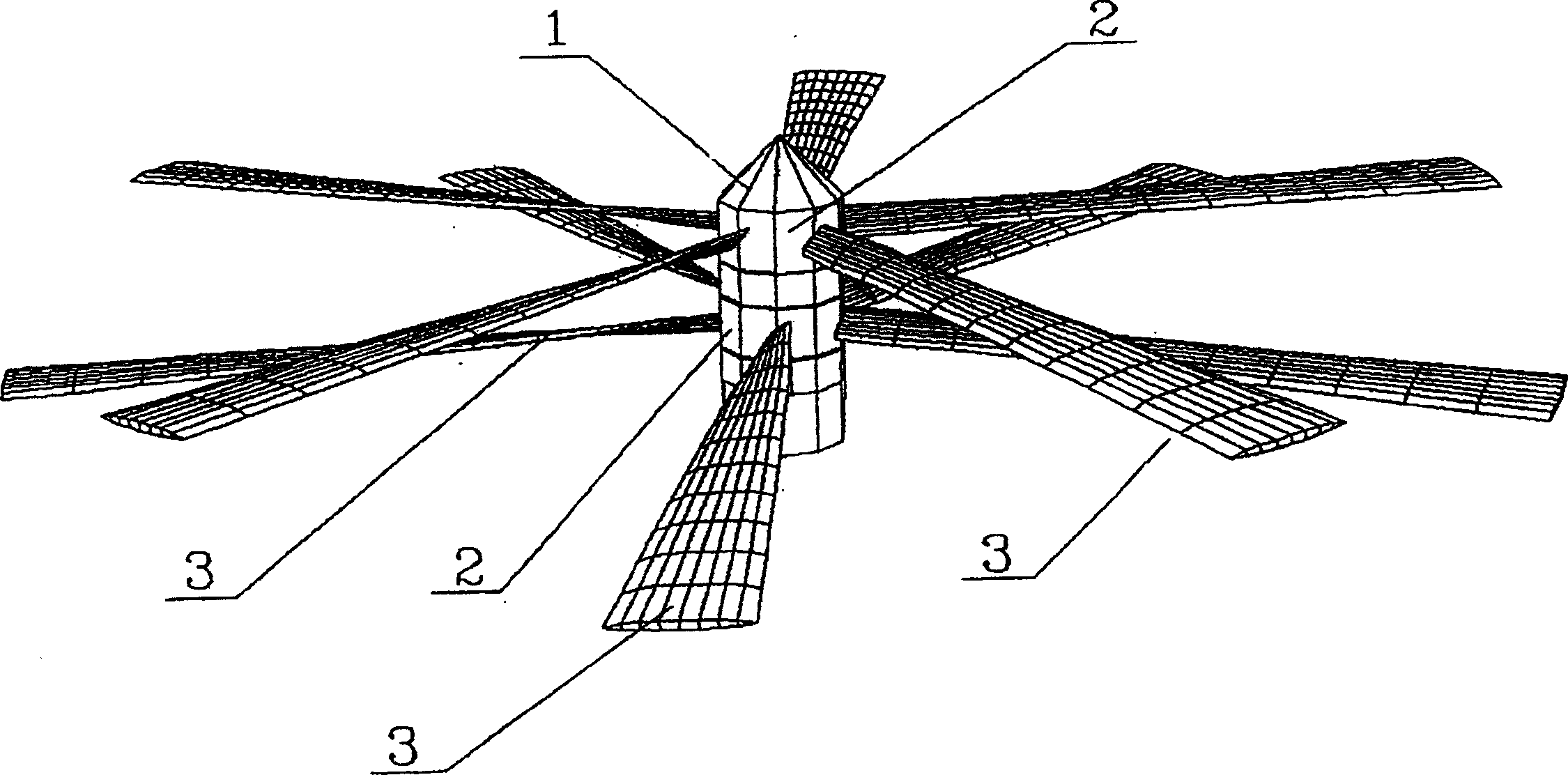

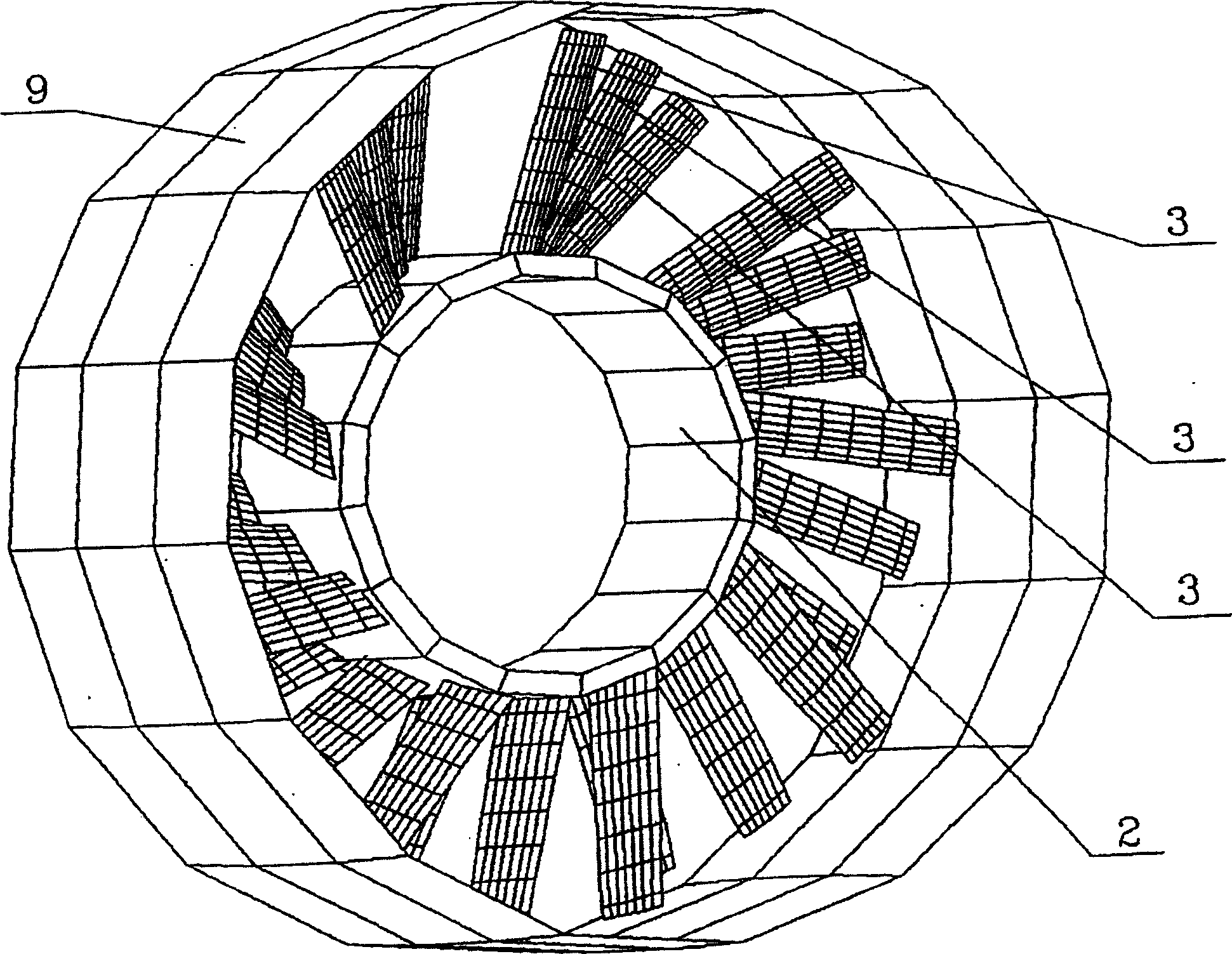

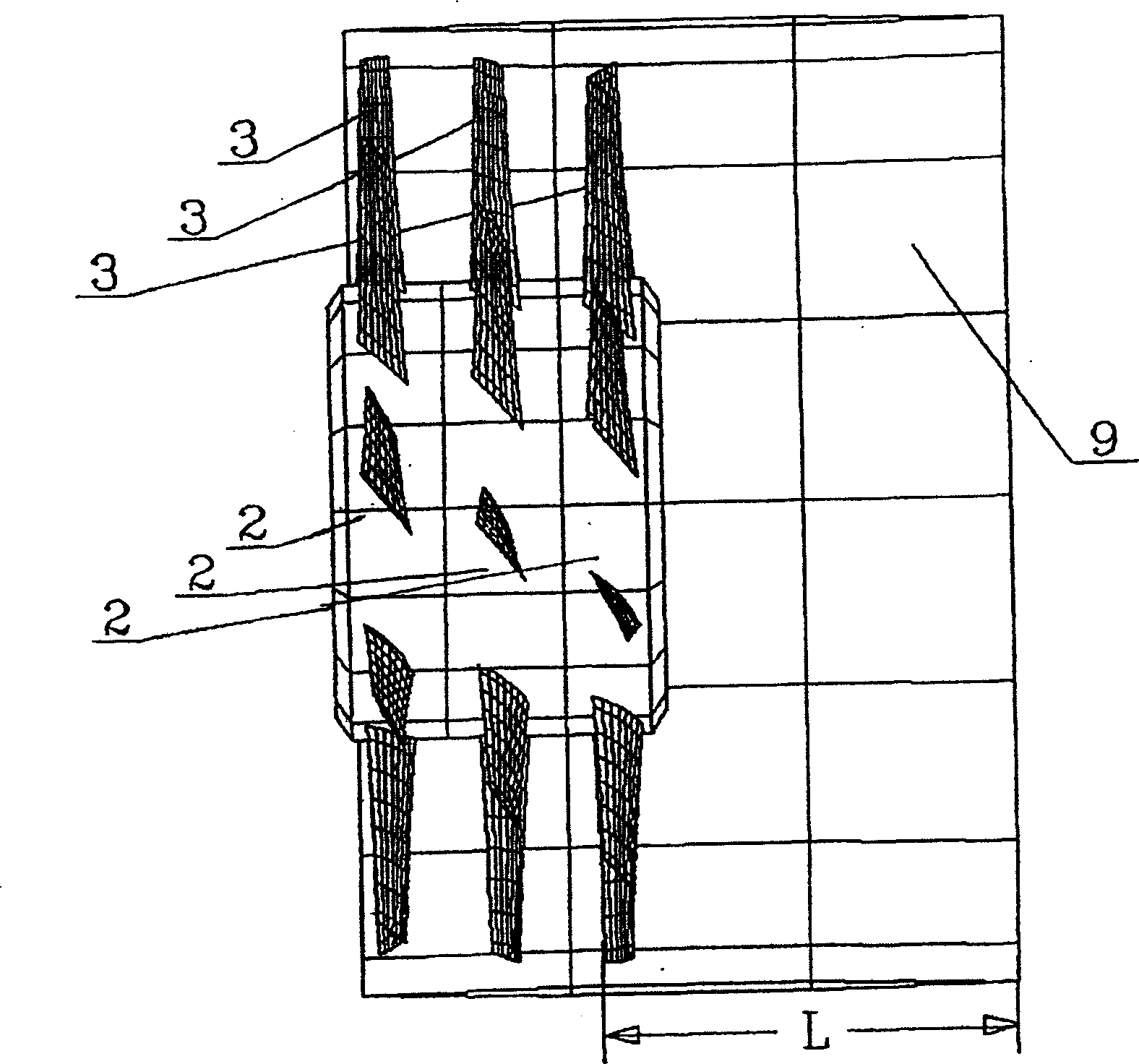

[0016] The propeller has a main shaft 1 on which at least two hubs 2 are arranged, and the main shaft 1 has blades 3 uniformly fixed on the circumference of each hub. The number of hubs with blades 3 can be different. The blades 3 on each sequential hub 2 can be fixed with the possibility of rotation in opposite directions, and with the possibility of rotation in one direction. This rotation can be performed by a motor through a drive shaft and a gear train.

[0017] Each blade 3 has a sharp front edge 4 and a sharp rear edge 5 and is configured along the extension of the blade 3 to have a maximum thickness (0.10-0.25) b of the profile, where b is the length of the local chord of the blade 3 .

[0018] In each blade 3 the maximum thickness 6 of the profile is located in the middle of each partial chord.

[0019] The profile can have different shapes, eg biconvex, wedge, rhombus. Profiles of different shapes can be formed along the extension of the blade.

[0020] Each blad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com