Hermetic rotary compressor and refrigerating circulatory device using the compressor

A rotary compressor, hermetic technology, used in compressors, parts of pumping devices for elastic fluids, and parts of rotary piston/oscillating piston pumps, etc., can solve the problem of unreliable lubrication and deflection of rotating shafts. Problems such as enlargement and deviation, to achieve the effect of reducing wear and tear and reducing the occurrence of failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Next, an embodiment of the hermetic rotary compressor of the present invention will be described with reference to the drawings.

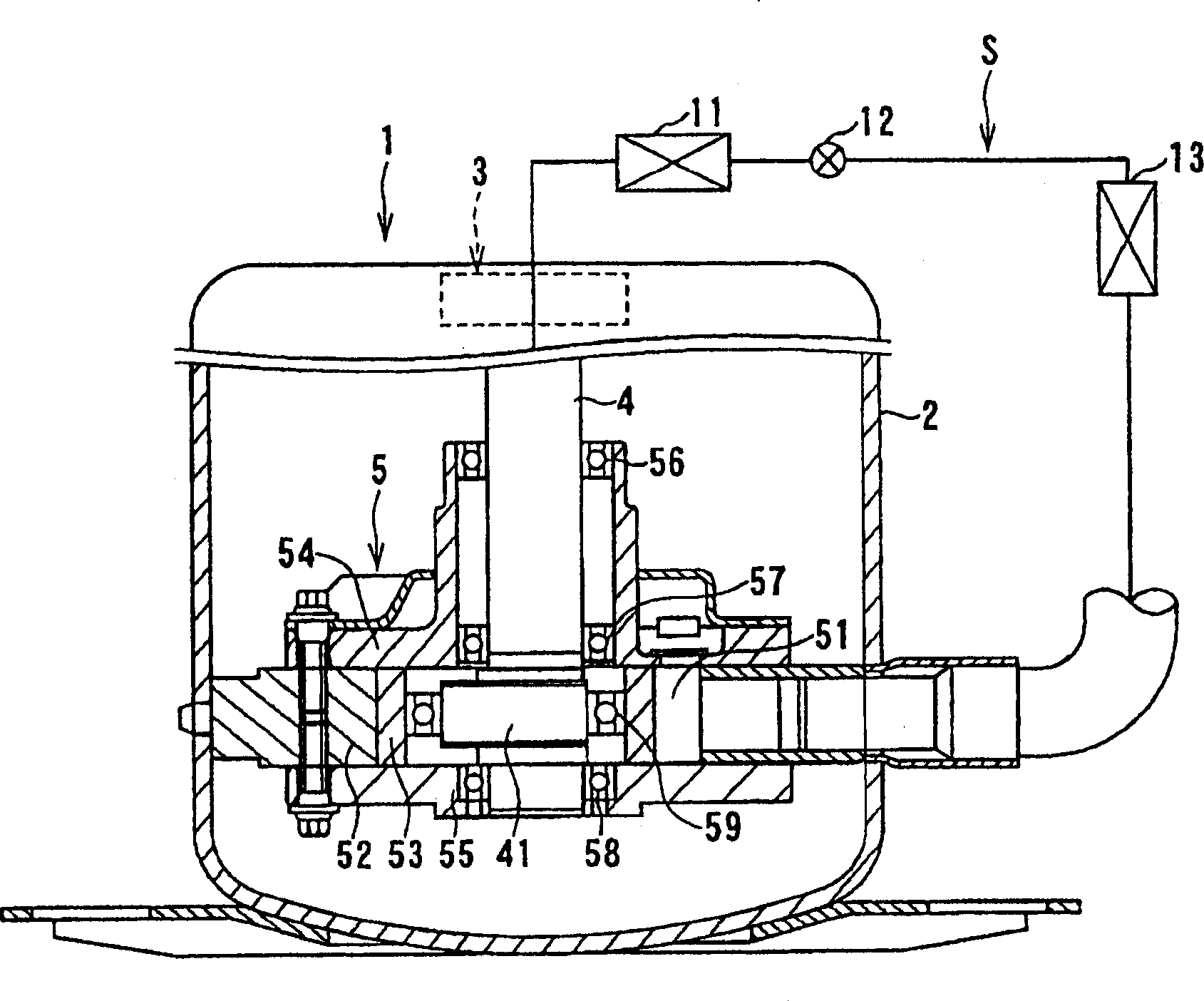

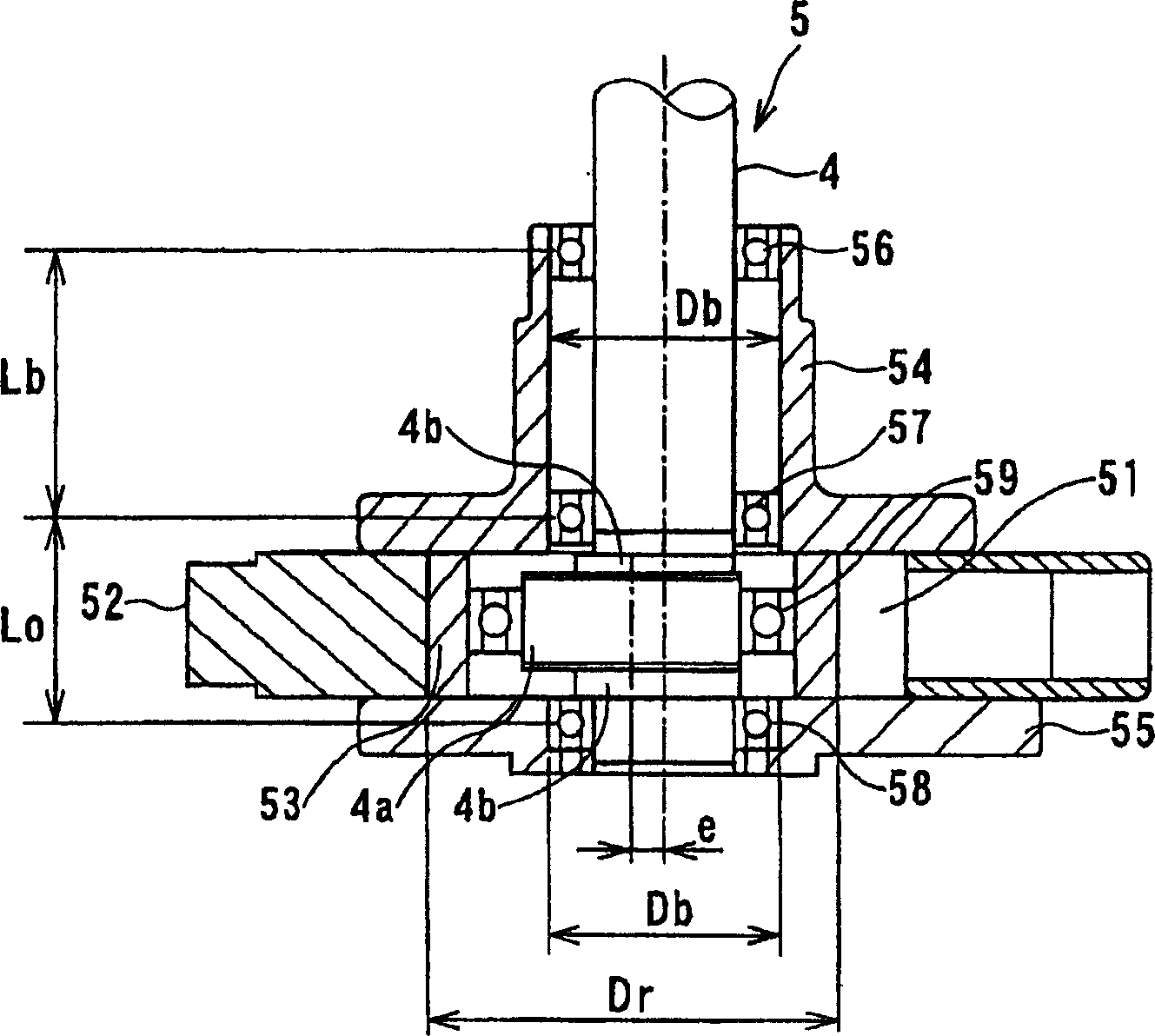

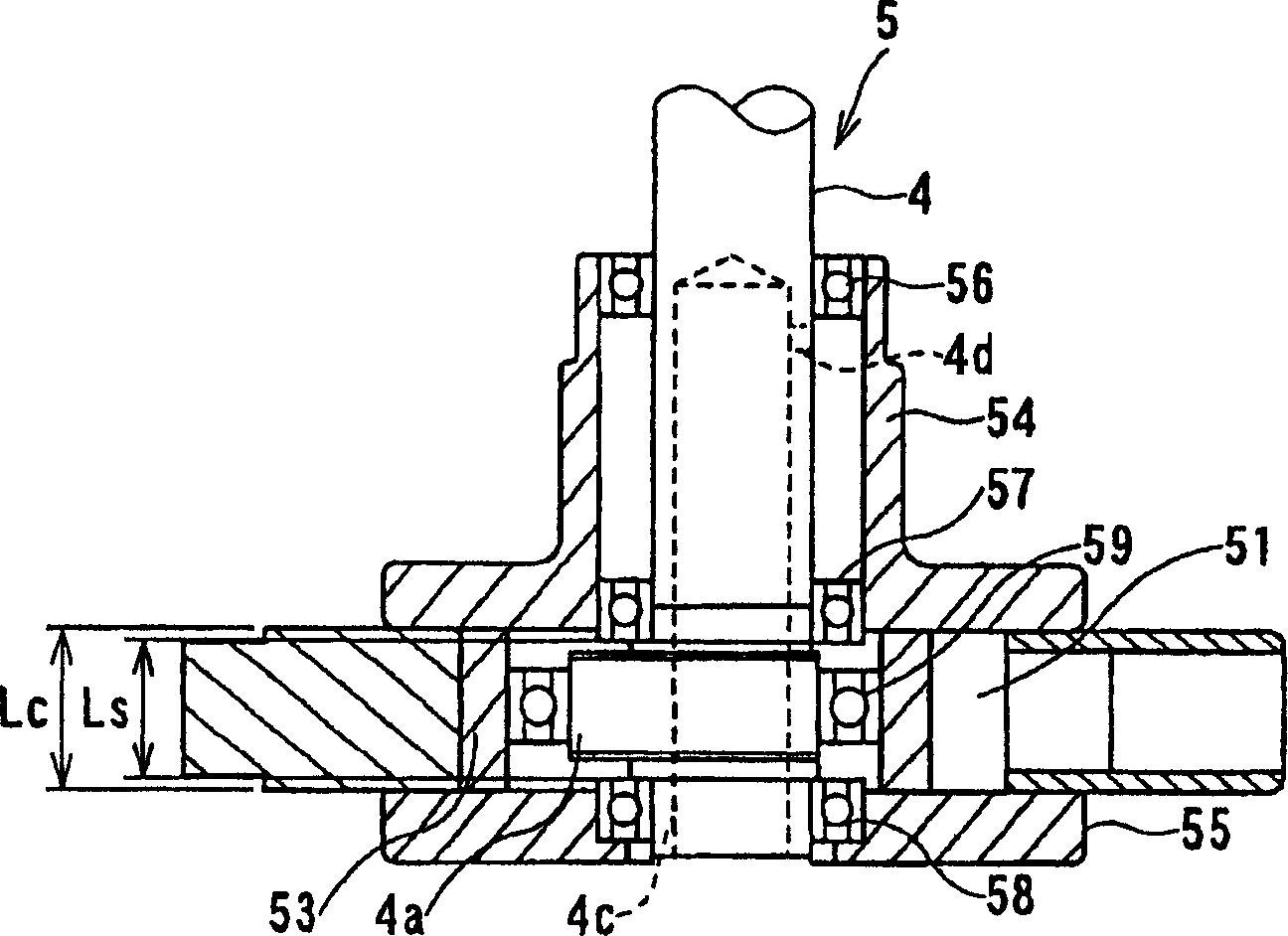

[0041] figure 1 It is a schematic diagram of the hermetic rotary compressor and refrigeration cycle device of the present invention, figure 2 It is an enlarged longitudinal sectional view showing the rotary compression member.

[0042] Such as figure 1 As shown, the refrigeration cycle device S of the present invention includes: the compressor 1 of the present invention, the condenser 11 , the expansion tube 12 and the evaporator 13 .

[0043] The compressor 1 of the present invention includes a sealed case 2 , and a motor 3 and a rotary compression member 5 connected to the motor 3 via a rotating shaft 4 are accommodated in the sealed case 2 .

[0044] Such as figure 1 and figure 2 As shown, the rotary compression member 5 includes: a cylinder block 52 forming a cylinder chamber 51 , a roller 53 fitted on the eccentric portion 4 a of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap