Rail fastening

A technology for rails and fasteners, applied in the field of railway systems, can solve the problems of low utilization rate of gauge pads, easy retention of water and oil pollution, unfavorable maintenance and repair, etc., and achieves the effect of easy maintenance and repair, multiple combinations, and material saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

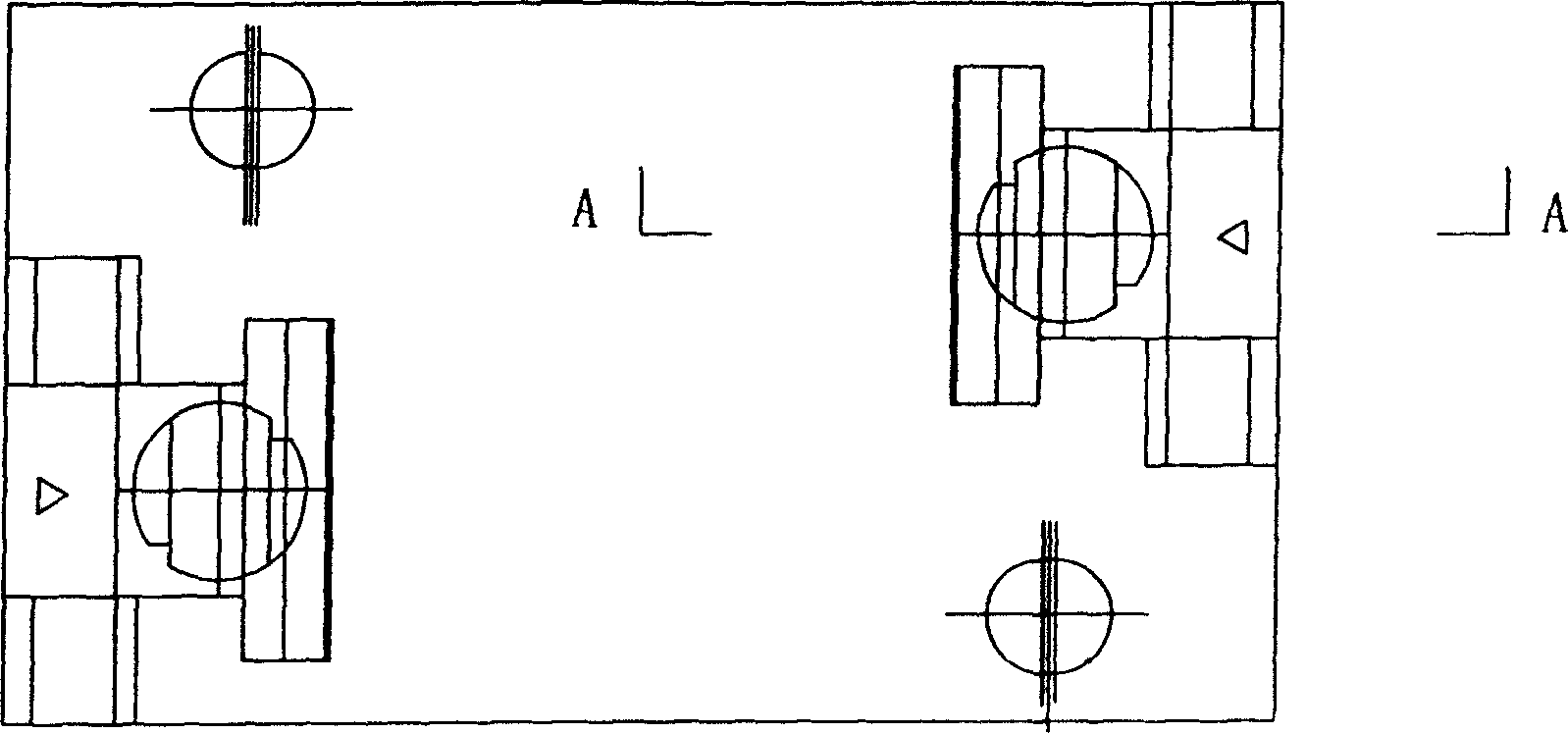

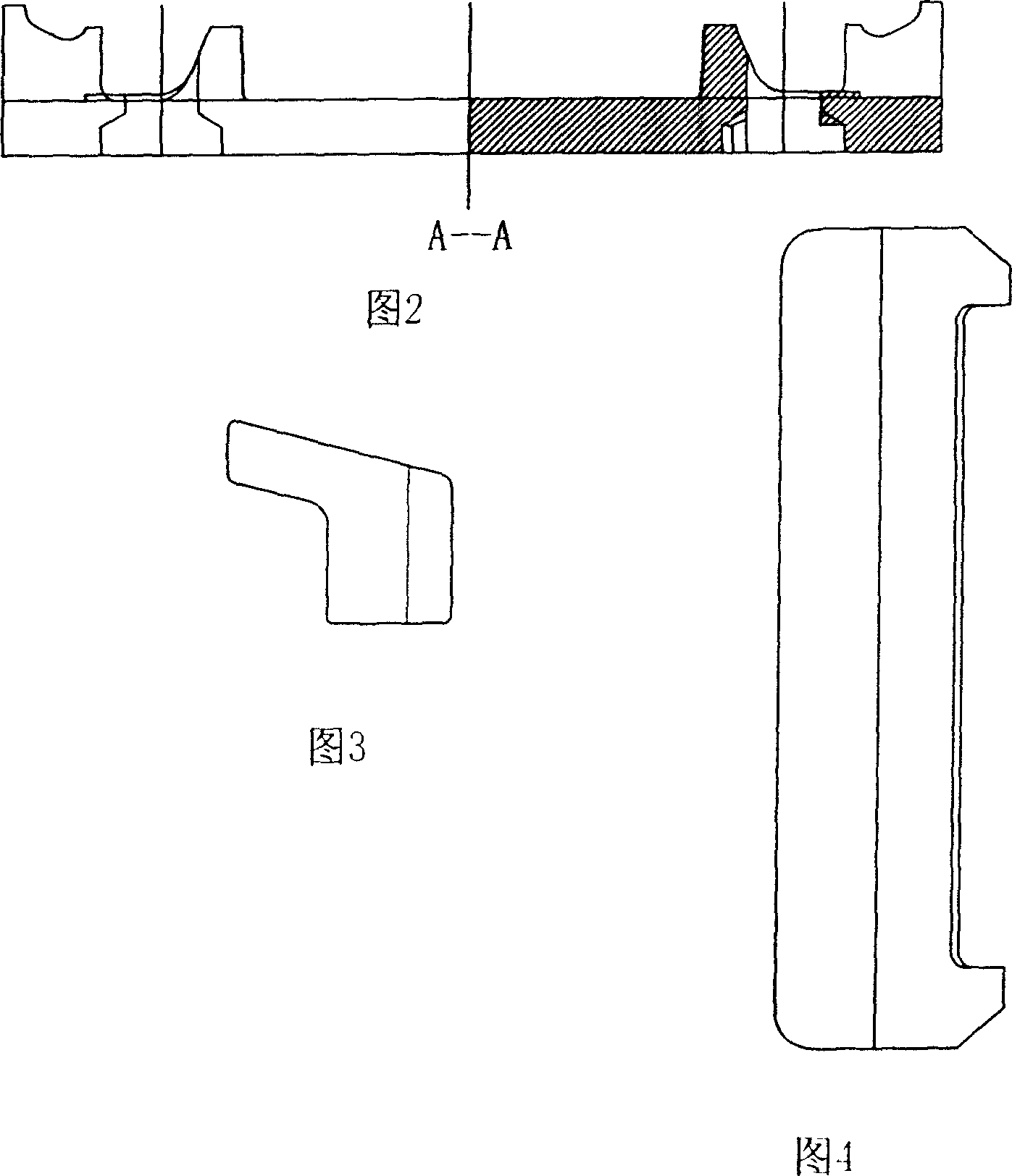

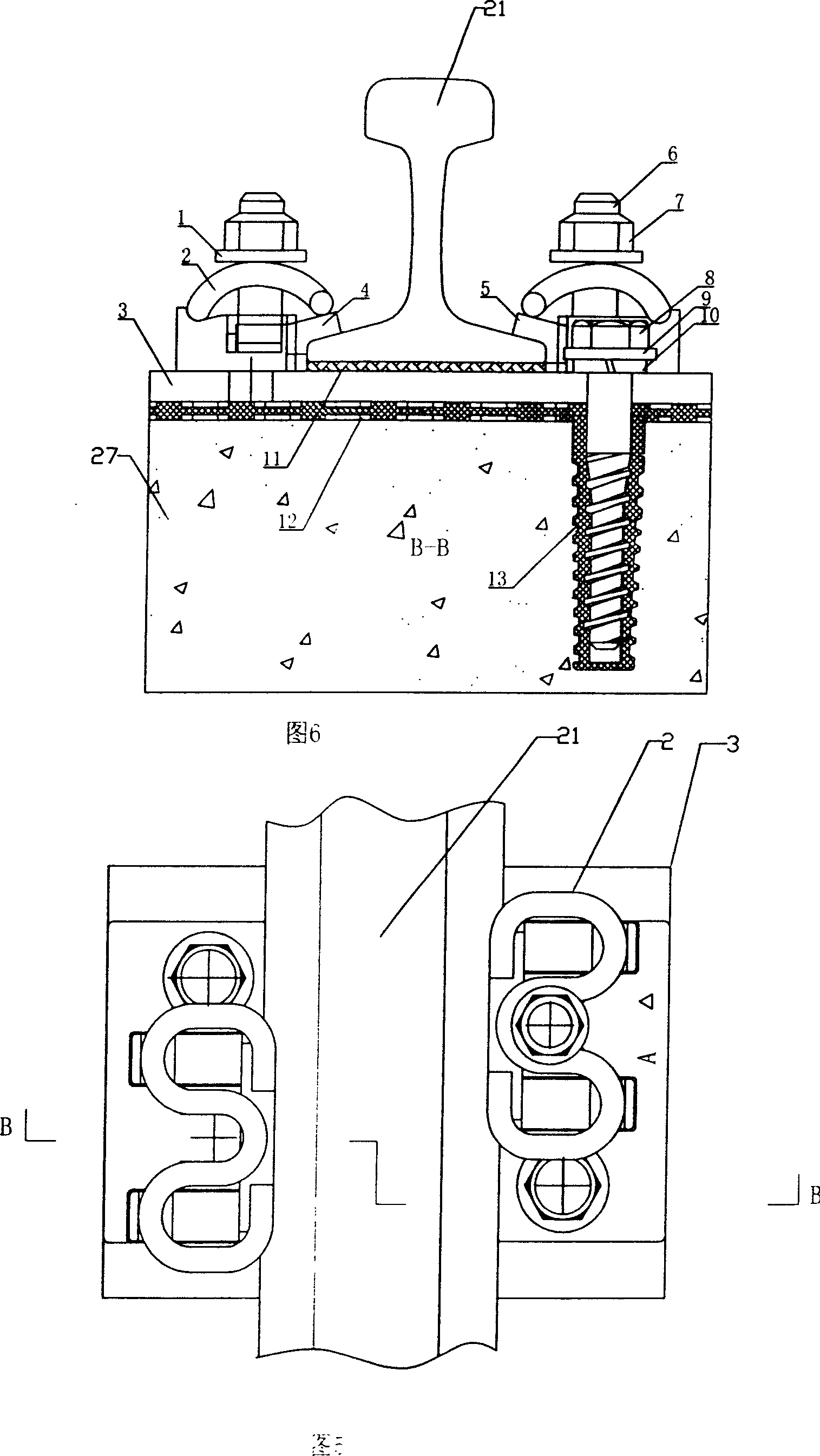

[0032] Embodiment: This embodiment includes a rail 21, an iron backing plate 3, a buckle B-shaped elastic strip 2, a T-shaped bolt 6, gauge pads 4, 5, and a T-shaped bolt 6, a flat washer 1, a nut 7 and a B-shaped The elastic strip 2 fastens and fixes the steel rail 21, the rubber backing plate 11 under the rail and the iron backing plate 3, and the iron backing plate 3 and the iron backing plate are fixed under the iron backing plate 3 through the anchor bolt 8, the flat washer 9, the heavy spring washer 10 and the insulating sleeve 13. The rubber backing plate 12 is fixed with the sleeper 27, and the four iron seats 14, 22, 23, 24 provided on the iron backing plate 3 and its surface are integrally cast, and an inverted structure is formed between the upper surface 16 of the iron seat and the surface 17 of the iron backing plate. T-shaped opening-shaped gap 18 , the T-shaped bolt 6 is embedded in the gap 18 upside down.

[0033] Iron seat 14 and iron seat 24 are a group, iron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com