Wide edge variable base hard alloy metal sheet for alloy drill bit

A technology of alloy drill bits and hard alloys, which is applied in the direction of drill bits, drilling equipment, earthwork drilling and mining, etc. It can solve the problems of high product cost, missing welding, lack of welding, and leaving gaps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

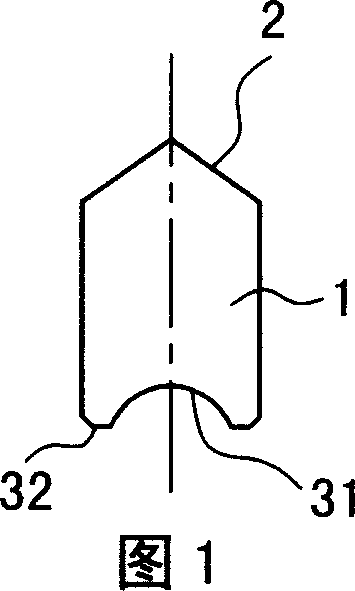

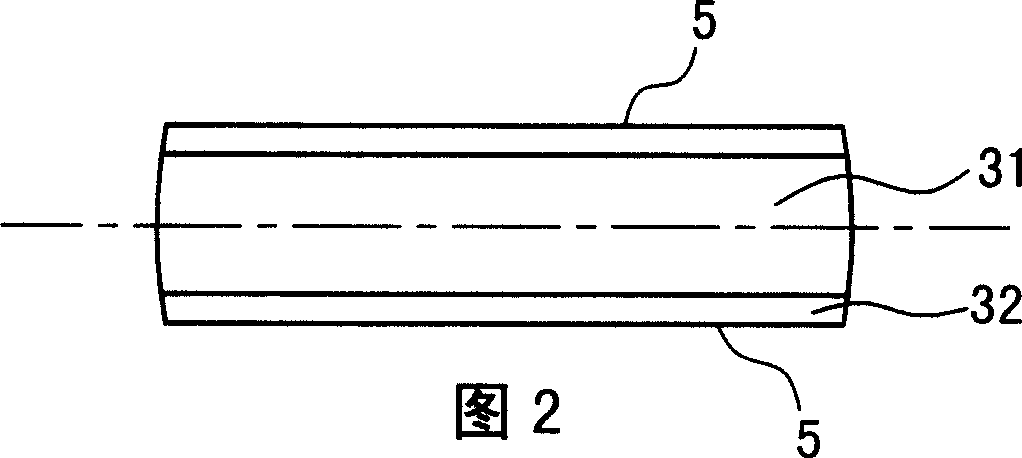

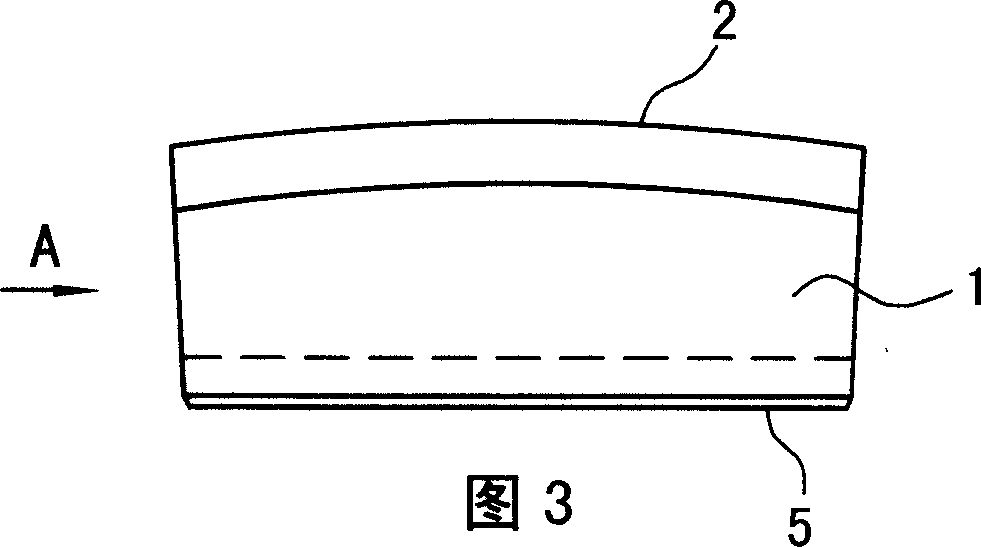

[0014] The invention discloses a cemented carbide sheet with a wide side and variable bottom surface for an alloy drill bit, which refers to an alloy sheet of a straight, cross, X-shaped, and three-edged drill bit, which consists of a main body 1 and a tip 2 of the alloy sheet. Composed, the long side bottom surface of the alloy sheet can be a plane 5, as shown in Figure 2 and Figure 3, its main technical feature is that the wide side bottom surface of the alloy sheet is a concave bottom surface. The broadside refers to the end face. If it is inline, it refers to the two ends (both ends). As shown in Figure 3, the A direction, the concave bottom surface is the concave curvature of the bottom line. As shown in FIG. 5 , the concave bottom surface is an arc-shaped concave bottom surface. A change from the flat bottom of the prior art. The concave bottom surface varies a lot. As shown in FIG. 1 , the wide-side bottom surface is a mixed bottom surface combining a flat surface 32 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com