Split air conditioner

An air conditioner and split-type technology, applied in the field of split-type air conditioners, can solve the problems of increasing the refrigerant flow resistance, affecting the service life of the compressor, slowing down the refrigerant flow speed, etc., so as to prolong the service life and improve the heat exchange efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

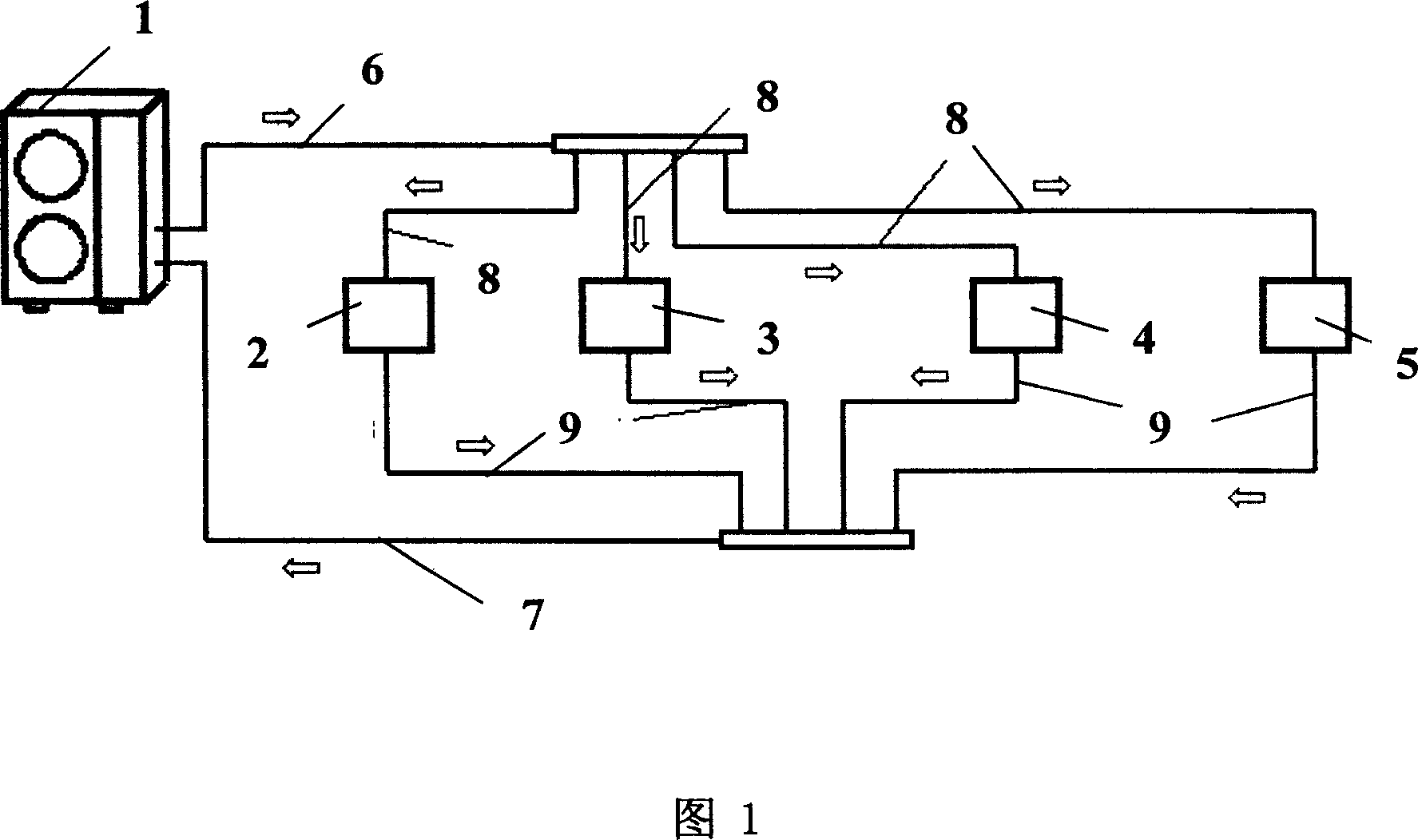

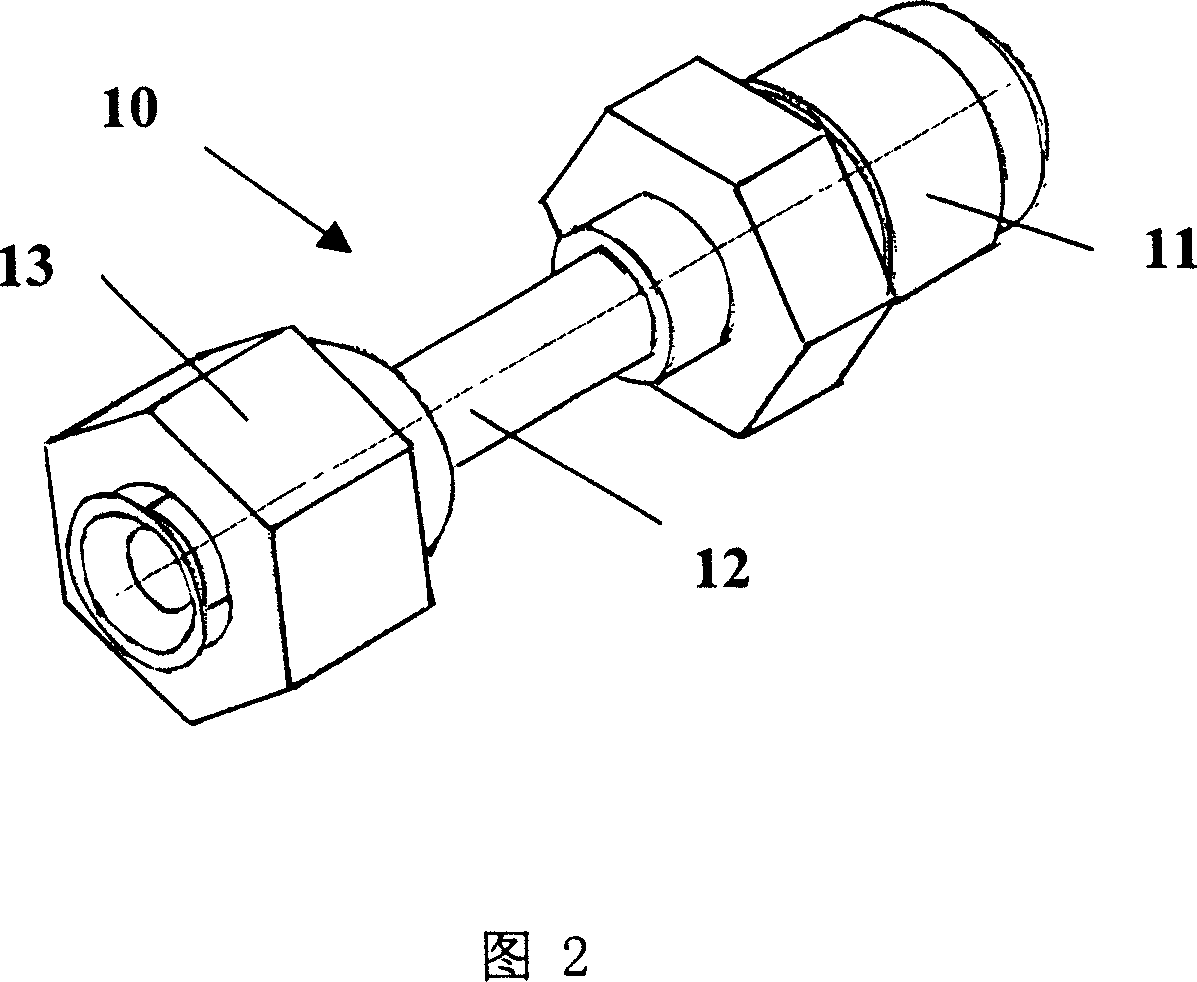

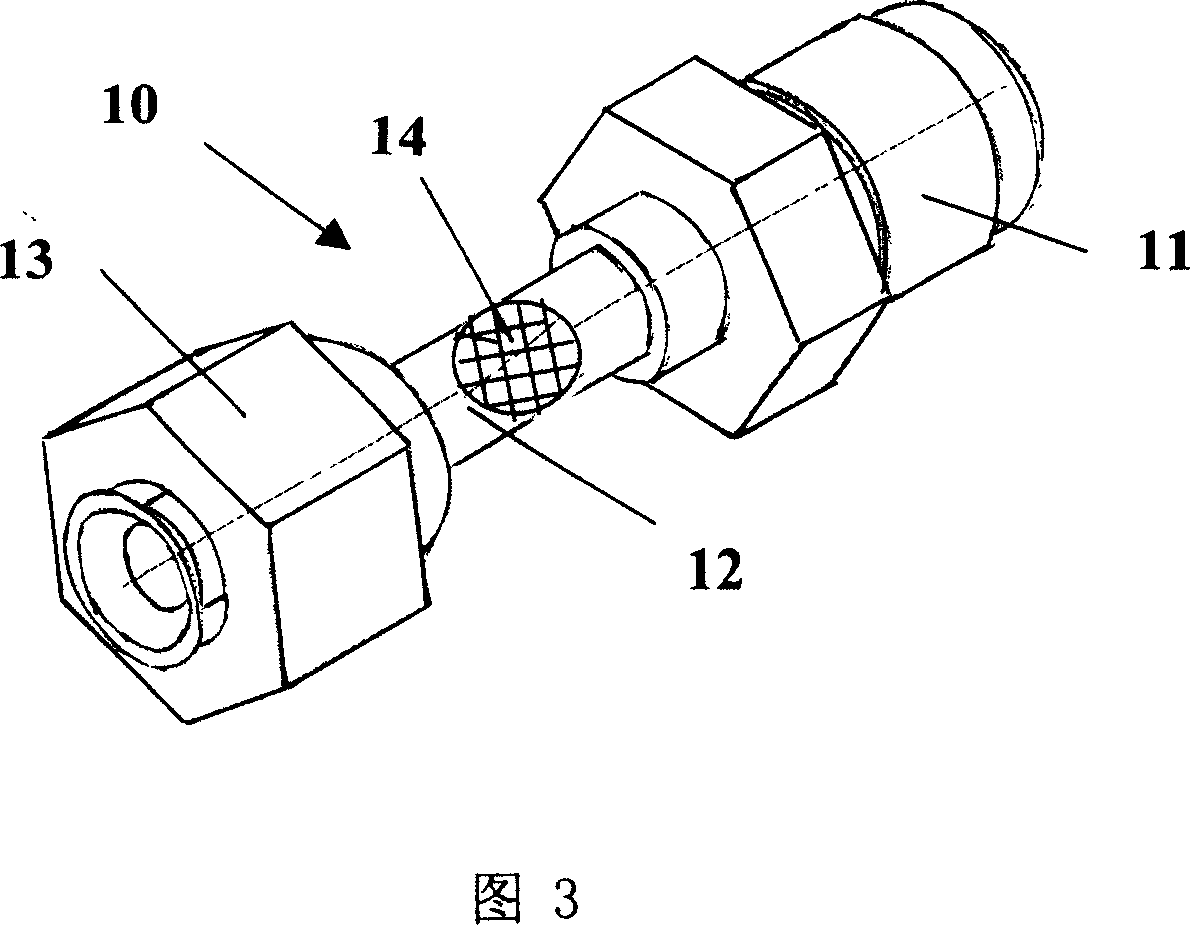

[0011] As shown in Figure 1 and Figure 3, the split type air conditioner provided by the present invention includes an outdoor unit 1 and at least one outdoor unit 2-5, the outdoor unit 1 is connected with a refrigerant output pipe 6 and a refrigerant input pipe 7, and The indoor units 2-5 are connected with the refrigerant input pipe 8 and the refrigerant output pipe 9 respectively connected with the refrigerant output pipe 6 and the refrigerant input pipe 7 of the outdoor unit 1, and the outdoor unit 1 and the indoor units 2-5 are connected by copper. The head 10 is connected to the respective refrigerant output pipes 6, 9 and refrigerant input pipes 7, 8; a filter 14 is installed inside the copper connector 10. The filter screen 14 is circular, and its outer circumference is fixed on the inner circumferential surface of the short copper pipe 12 . When the split-type air conditioner provided by the present invention performs cooling operation, the compressor installed in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com