Curvilinear optical modulation component and backlight module with same

An optical modulation, backlight module technology, applied in nonlinear optics, optics, instruments, etc., can solve the problems of moire, unsuitable for mass production, and high difficulty in array structure processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

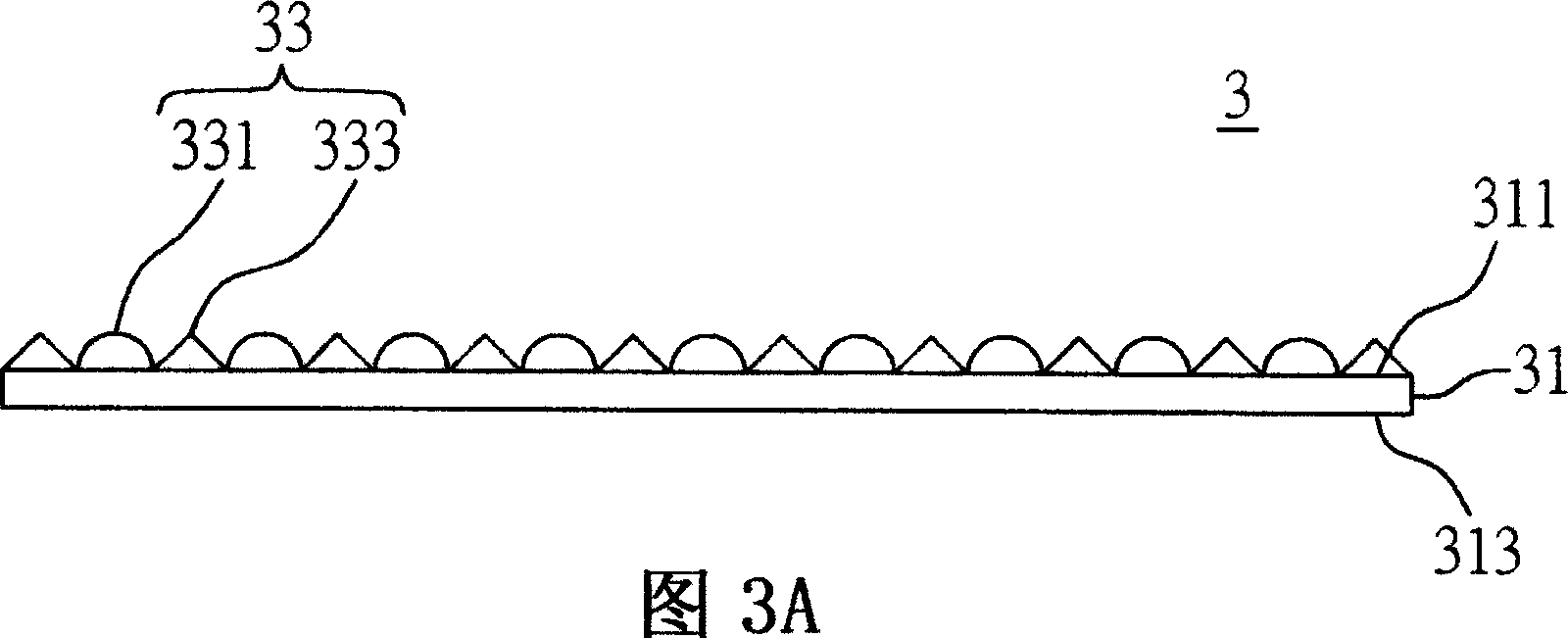

[0034] 3A to 5 are drawings drawn according to Embodiment 1 of the curved optical modulation element and the backlight module having the modulation element of the present invention.

[0035] Please refer to FIG. 3A , which is a cross-sectional view of the structure of the curved optical modulation element of the first embodiment. The curved optical modulation element 3 shown in the figure includes a light-transmitting substrate 31 and a curved microstructure 33 . Wherein the curve may be a curve function such as a trigonometric function sin(x), cos(x) and the like.

[0036] The transparent substrate 31 has a first optical surface 311 and a second optical surface 313 opposite to each other. In the first embodiment, the light-transmitting substrate 31 may be a transparent substrate, a transparent film or other equivalent transparent elements. The second optical surface 313 can be selected as a smooth optical surface or an optical surface with a rough undulating structure, and ca...

Embodiment 2

[0047] 6A to FIG. 7 are drawings drawn according to Embodiment 2 of the curved optical modulation element and the backlight module having the modulation element of the present invention. Wherein, the same or similar components as in Embodiment 1 are represented by the same or similar component symbols, and detailed descriptions are omitted to make the description of this case clearer and easier to understand.

[0048] The biggest difference between embodiment 2 and embodiment 1 is that, in the curved optical modulation element of embodiment 2, the extension direction of the curve of the diffusion part and the light collection part is perpendicular to the first optical surface, and the backlight module also includes A reflection sheet located under the light guide plate.

[0049] Please refer to FIG. 6A , which is a cross-sectional view of the structure of the curved optical modulation element of the second embodiment. In the curved optical modulation element 3 of Embodiment 2...

Embodiment 3

[0052] 8 to 9 are diagrams drawn according to Embodiment 3 of the curved optical modulation element and the backlight module having the modulation element of the present invention. Wherein, the same or similar components as those in the above-mentioned embodiments are denoted by the same or similar component symbols, and detailed descriptions are omitted.

[0053] The biggest difference between Embodiment 3 and the above embodiments is that the diffusion part and the light collecting part are arranged in equal proportions and spaced side by side, and the difference from Embodiment 2 is that the backlight module also includes a curved optical modulation element. protective film.

[0054] Please refer to FIG. 8 , in the curved optical modulation element 3 of the third embodiment, the diffusing portion 331 and the light collecting portion 333 are arranged side by side at equal intervals, for example, two light collecting portions 333 are matched with two diffusing portions 331 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com