Improving structure for compressor motor rotor balancing block

A technology of motor rotor and balance weight, which is applied in the field of compressors, can solve the problems of increasing the material cost of compressor motor parts and the large amount of copper materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Now further illustrate specific embodiments of the present invention in conjunction with accompanying drawings.

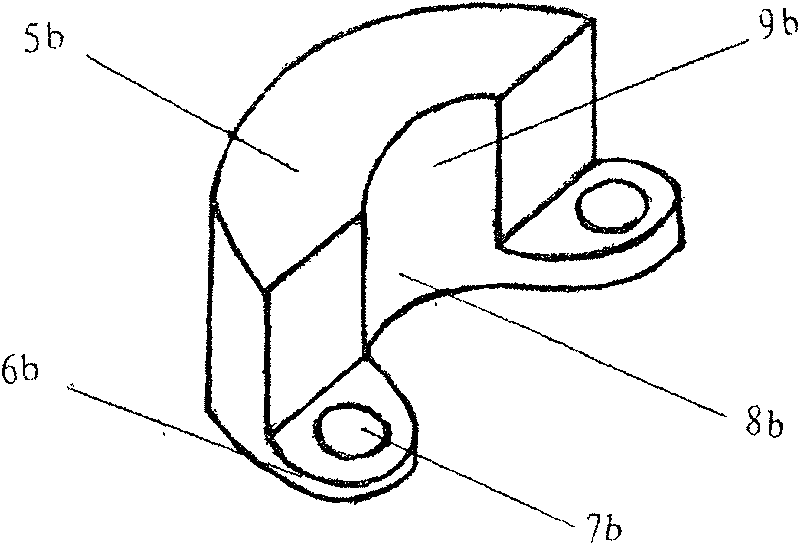

[0024] image 3 It is an improved structural diagram of the motor rotor balance weight of the present invention. Such as image 3 As shown, the balance weight of the motor rotor of the compressor involved in the present invention is an arc-shaped body, which is integrally formed by the upper protrusion 5b and the lower bottom bracket 6b. Both ends of the bottom bracket 6b protrude inwardly. Both ends of the bottom bracket 6b protrude toward the inner side, and the end faces are protruding surfaces, and a through hole 7b is provided in the center of the protruding portion. The bolt passing through the through hole 7b fixes the balance weight on the rotor of the motor.

[0025] The inner arc surface 8b of the bottom bracket 6b is connected with the inner arc surface 9b of the protrusion 5b, and the inner arc surface of the bottom bracket 6b and the protrus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com