Method and auxiliary agent for producing concrete elements, especially concrete semi-finished products and/or concrete surfaces, and auxiliary agent for producing concrete surfaces

A technology of concrete slabs, concrete, used in the direction of manufacturing tools, floor slabs, building components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

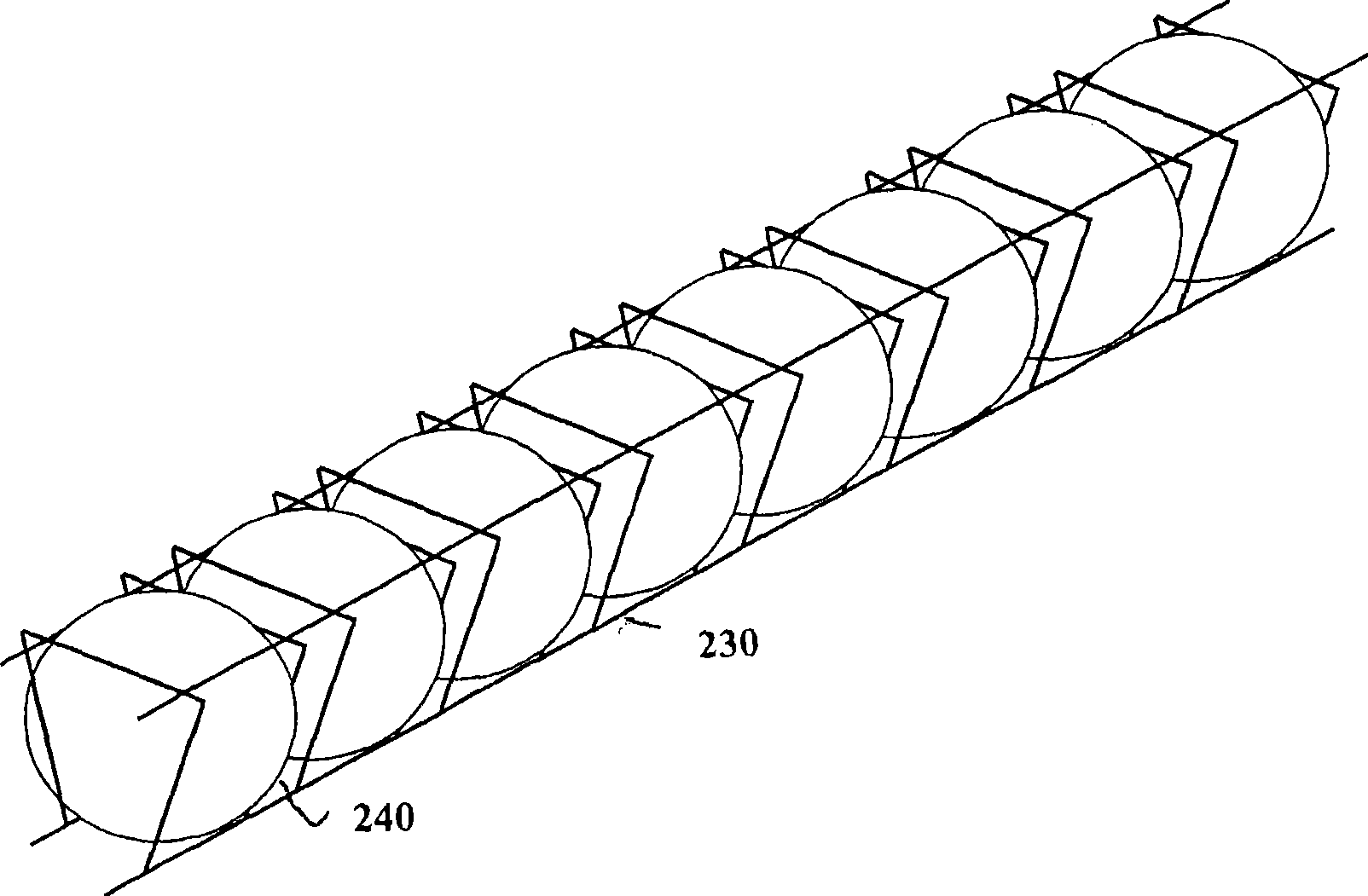

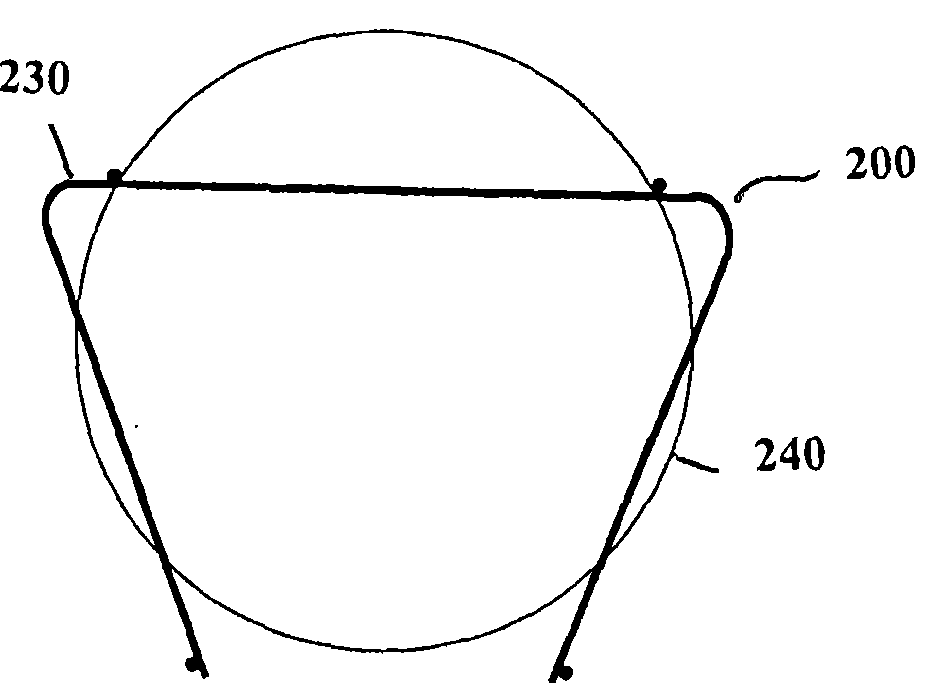

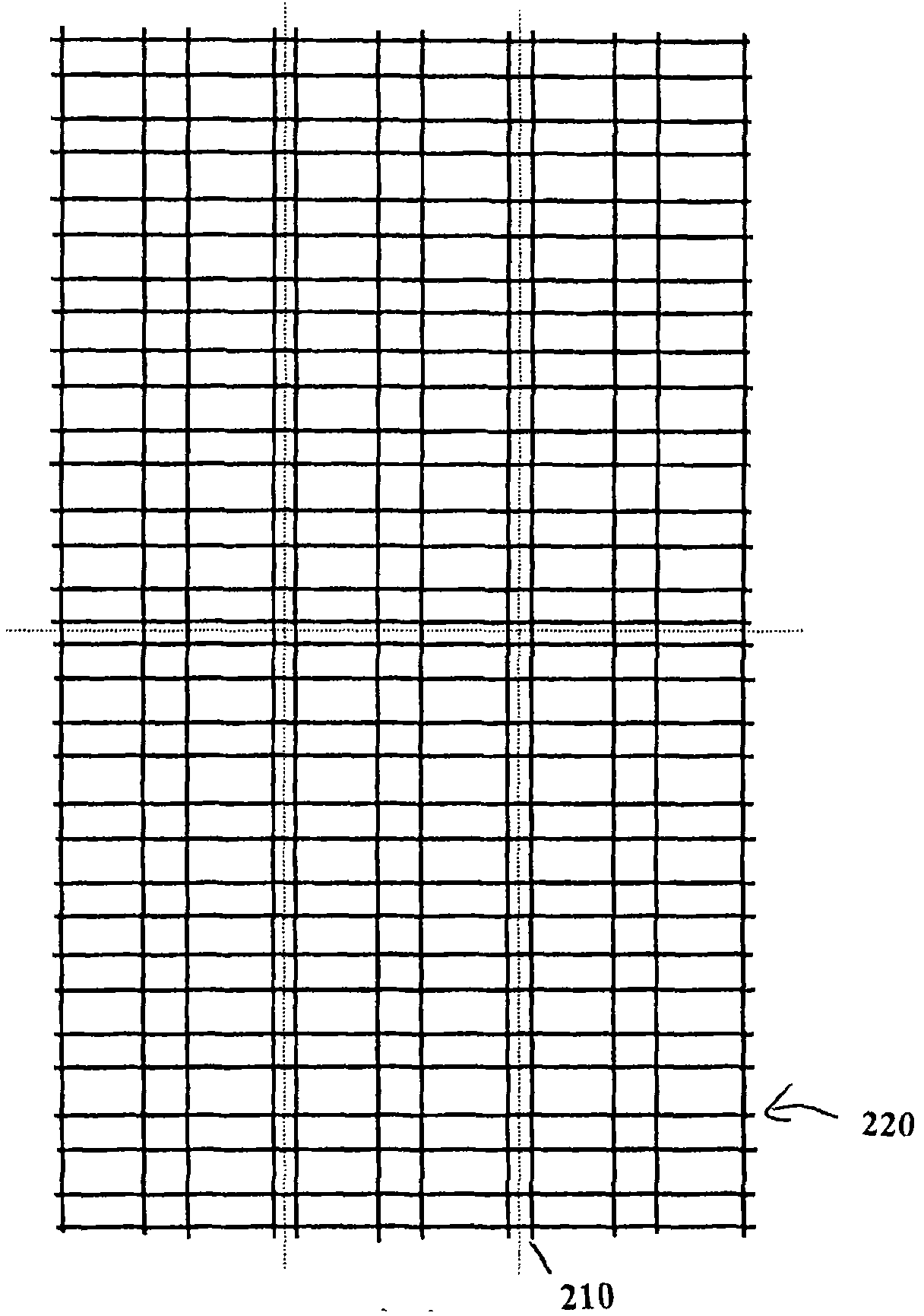

[0038] exist figure 1 and figure 2 The module according to the first embodiment is denoted by reference numeral 200, which module is made by having as image 3The shown dimensioned wire mesh 220 constitutes the form of the element, which is then bent approximately 95 degrees along the two inner rods. In the embodiment shown in the figure, 8 to 10 plastic balls 240 (plastic spheres) can be pressed into the downwardly open grid structure 230. The grid is slightly loose. In the illustrated embodiment, the grid structure is made such that the plastic balls 240 protrude upwardly from the grid. Therefore, structural stability can be ensured.

[0039] In a particular embodiment of the invention, the surrogate is not a solid sphere, but is flattened on the top surface so as to form a defined plane which is more suitable for a person to walk on. In this case, the surrogate has a directional position.

[0040] In another embodiment, which can be combined with the above-described ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com