Fan-shaped cast-in-place hollow floor type storage tank leveling foundation and construction method thereof

A technology for storage tank foundations and hollow floors, which can be applied to foundation structure engineering, protection devices, buildings, etc., and can solve the problems of difficulty in satisfying the characteristic value of the horizontal bearing capacity of single piles, increased project investment, and large horizontal seismic forces of storage tank foundations. problems, to achieve the effect of saving construction procedures, simplifying construction procedures and reducing earthquake response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

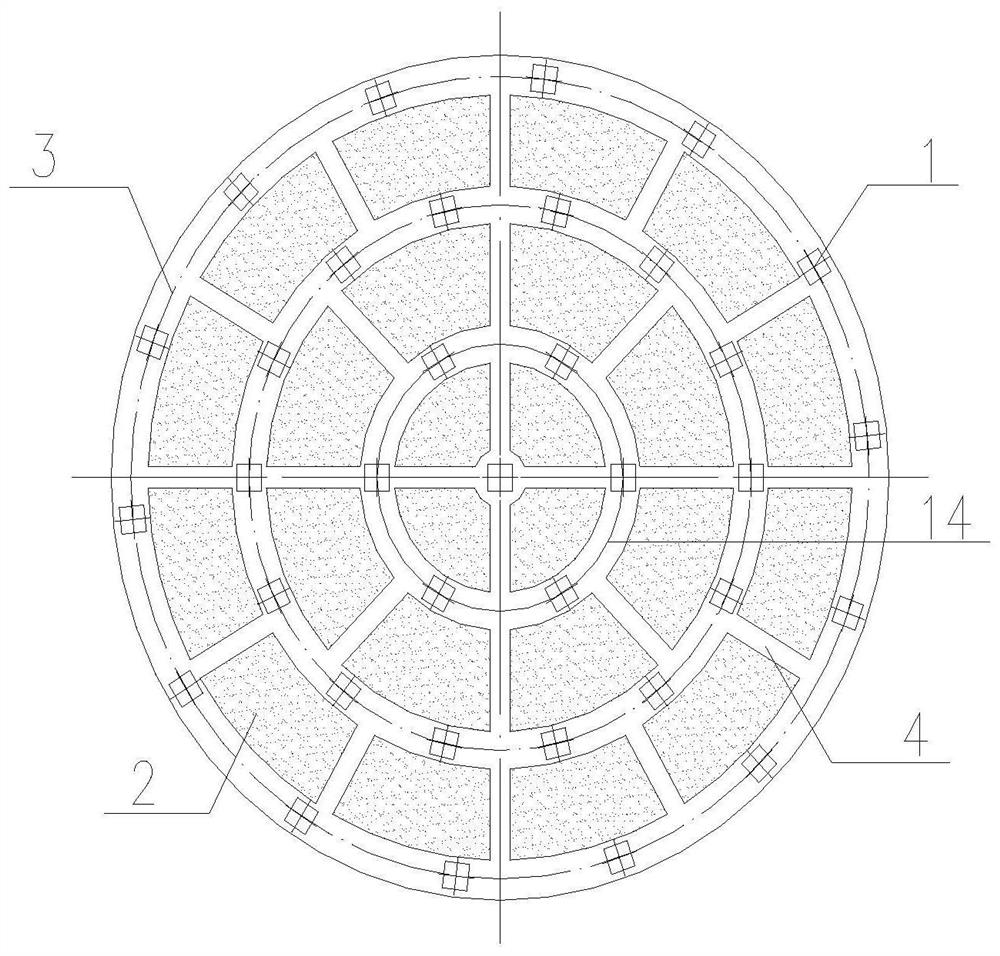

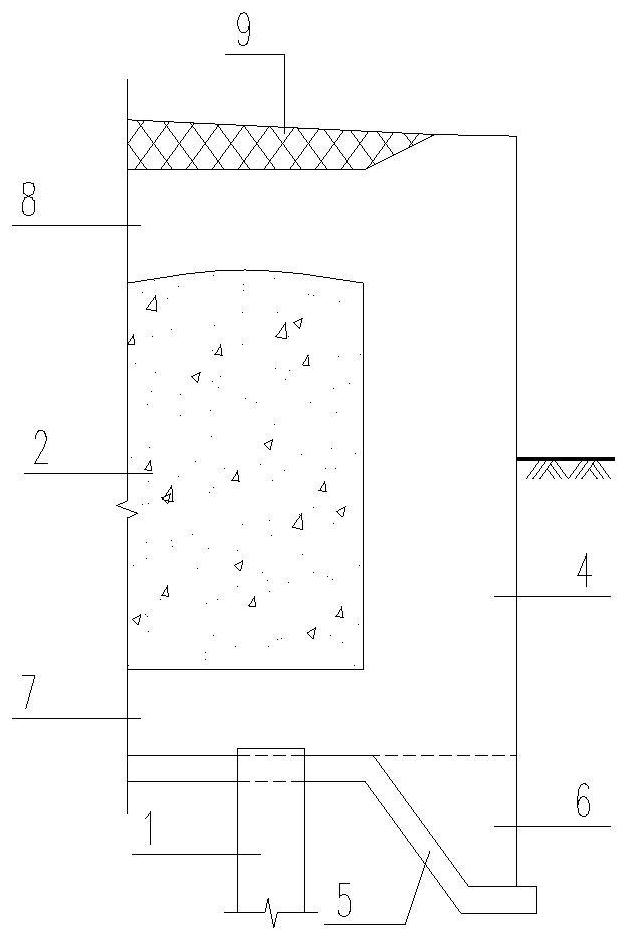

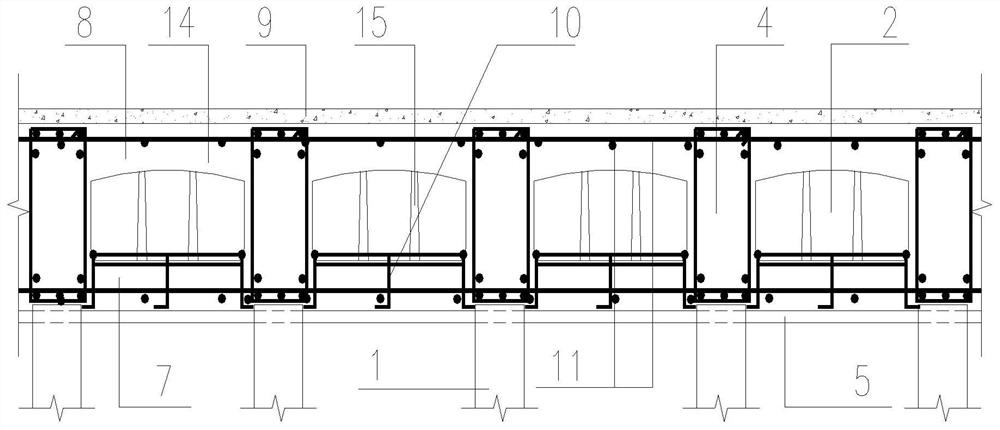

[0039] The present invention will be further described below in conjunction with the accompanying drawings of the description.

[0040] Such as Figure 1-2 As shown, a fan-shaped arrangement of cast-in-situ hollow floor storage tank leveling foundation, including storage tank foundation pile foundation 1, storage tank foundation plain concrete cushion 5, fan-shaped arrangement of cast-in-situ hollow floor storage tank leveling The foundation 14 and the asphalt sand cushion 9 are composed of the cast-in-place hollow floor storage tank leveling foundation 14 arranged in a fan shape as a toe-type foundation raft, and the plain concrete cushion 5 of the storage tank foundation is set on the pile foundation 1 and the foundation storage tank foundation. Between the fan-shaped cast-in-place hollow floor storage tank leveling foundations 14, the asphalt sand cushion layer 9 is arranged on the fan-shaped cast-in-place hollow floor storage tank leveling foundations 14.

[0041] Among t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com