Method and device for filling a container with a predetermined quantity of fluid and related filling machine

A kind of filling equipment and pre-measurement technology, applied in liquid filling, liquid bottling, liquid treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

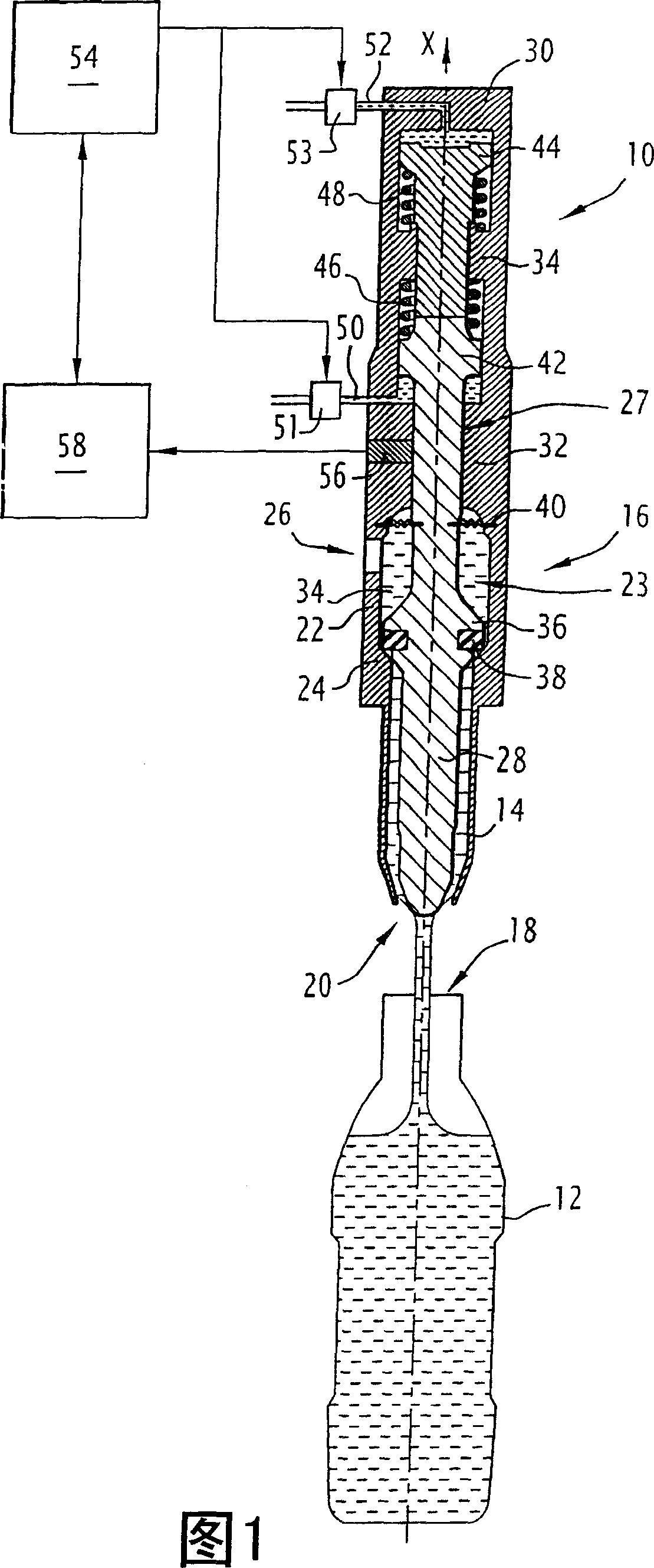

[0016] In the following description, the terms "above", "below", "high", "low", etc. refer to a vertical axis X along which the container and the filling device generally extend and along which the fluid flows. A straight axis X flows from the filling device to the container. The container is located below the filling device.

[0017] The filling device shown in FIG. 1 is denoted by reference number 10 . It is to fill a container 12, in this case a bottle, with a fluid which may be water or any type of liquid.

[0018] The filling device 10 comprises a nozzle 14 for delivering a flow of fluid along a vertical axis X into the container 12 , and a valve 16 for controlling the flow of fluid through the nozzle 14 .

[0019] The nozzle 14 is in the shape of a vertical tube which is located above the opening 18 of the container 12 . The diameter of the tube decreases near its lower end 20 , which faces the opening 18 .

[0020] Valve 16 comprises an outer housing 22 extending up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com