Production process of silicon single crystal

一种硅单晶、熔融硅的技术,应用在单晶生长、单晶生长、化学仪器和方法等方向,能够解决适应性及应用性差、成本上拉晶体次数指数增加等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100] Embodiment 1 corresponds to claims 1 and 3 .

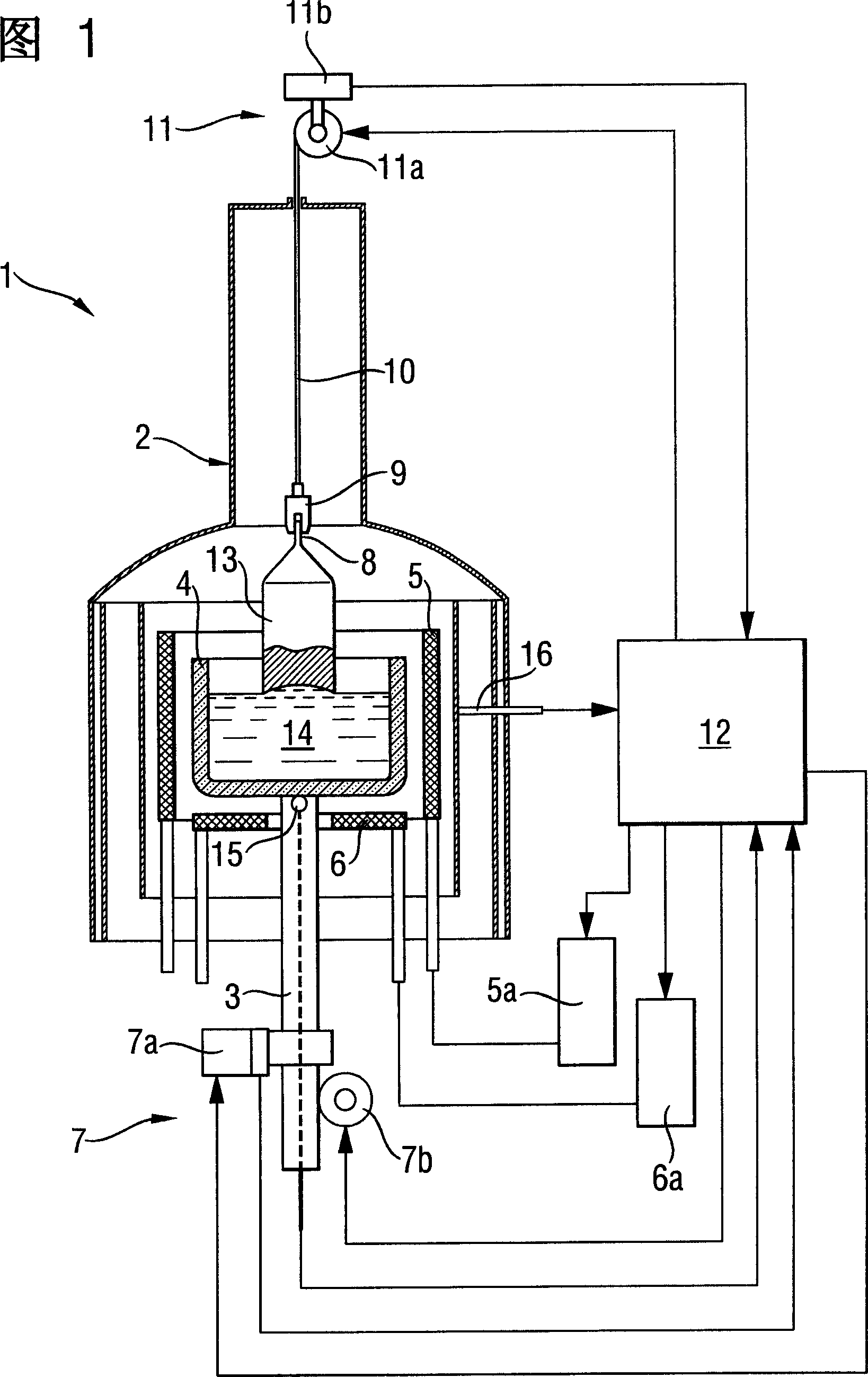

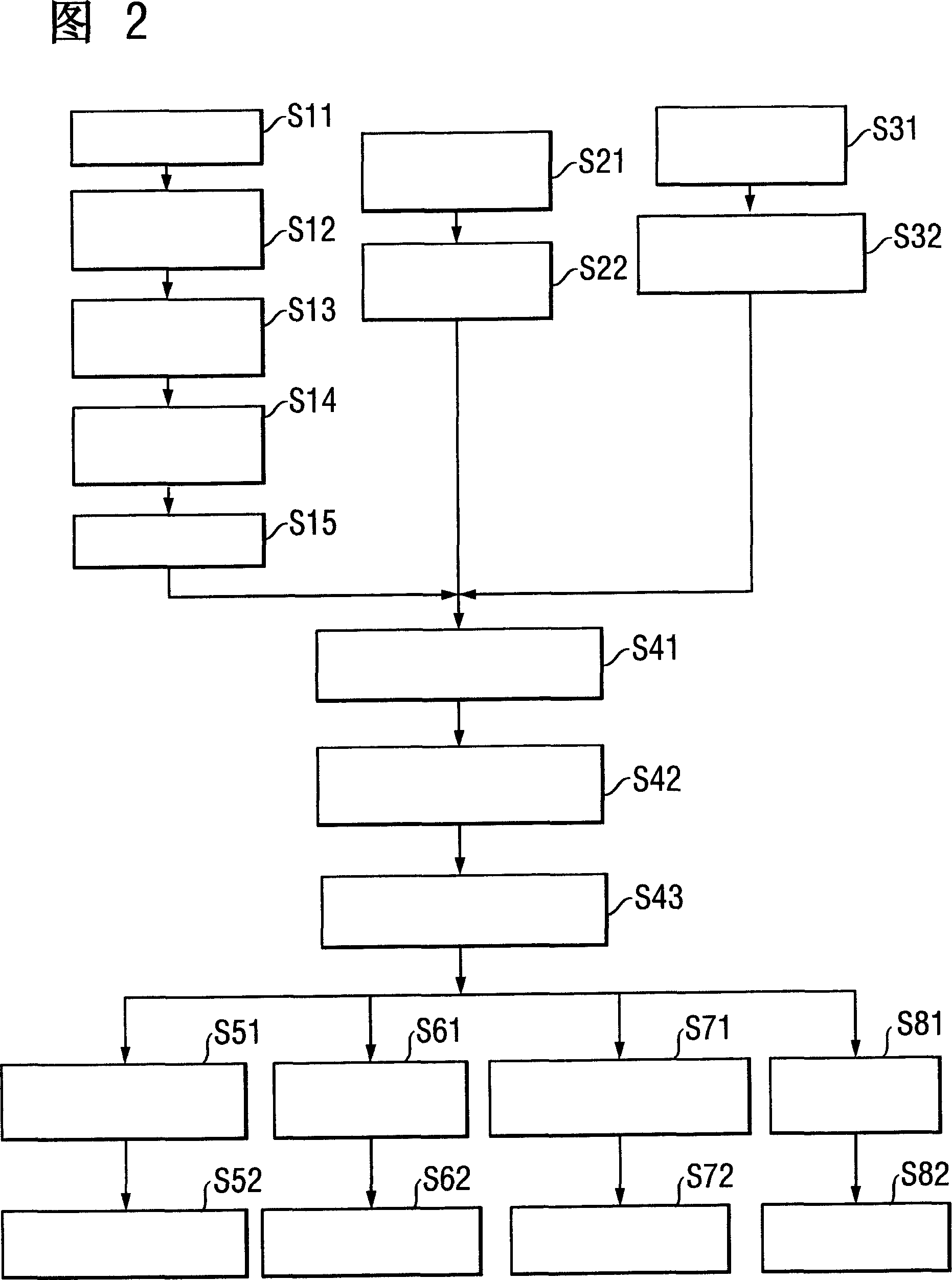

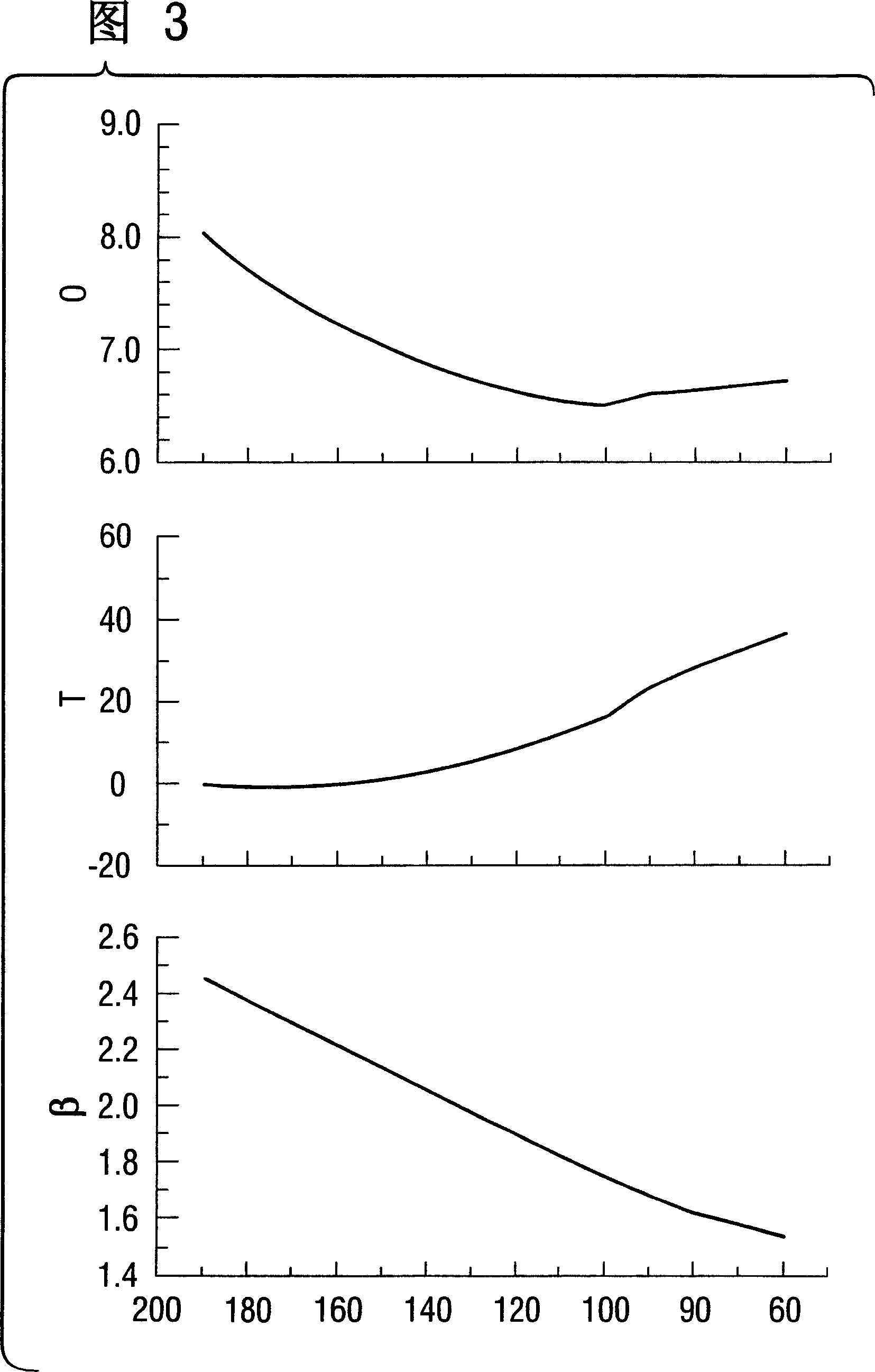

[0101]Grow a 12-inch crystal in the same crystal pulling furnace and furnace assembly as Comparative Example 1, so that the oxygen concentration in the crystal becomes 8.0×10E uniformly 17 (atoms / cubic centimeter), the crucible temperature was controlled by changing the crucible rotation speed during crystal growth. Specifically, in the initial stage of single crystal pull-up, the rotation speed of the crucible is relatively low, and in the later stage of growth, the rotation speed is increased or decreased according to the flowchart shown in FIG. 2 . The respective functions F, G and H for oxygen concentration used within governing equation (1) have the following form:

[0102] F(Ω)=Ω 0.5

[0103] G(T)=T+g Equation (7)

[0104] H(β)=β -1

[0105] The constants A, B and g are determined by the operating conditions of Example 1 and the oxygen concentration of the actually obtained crystals by the least square method. ...

Embodiment 2

[0109] Embodiment 2 corresponds to claims 2 and 3 .

[0110] In Example 2, a 12-inch crystal was grown in the same crystal pulling furnace and hot zone as Comparative Example 1, so that the oxygen concentration in the crystal was evenly changed to 8.0×10E 17 (atoms / cubic centimeter), as in Example 1, the crucible temperature T is controlled by changing the crucible rotational speed Ω in the crystal growth. Specifically, the crucible rotation speed Ω is kept low at the initial stage of single crystal pull-up, and the rotation speed is increased or decreased according to the flow chart shown in FIG. 2 near the later stage of growth. The respective functions F and I of oxygen concentration used in prediction equation (5) have the following form:

[0111] F(Ω)=Ω 0.5

[0112] I(T)=1 / β×Exp(-E / T)

[0113] In addition, the value of E is 24,000 (K), which is an approximate value disclosed in the reference (T, Carberg, J. Electrochem Soc., Vol. 133, No. 9, p. 1940), and the constant...

Embodiment 3

[0117] Embodiment 3 corresponds to claims 3 and 4 .

[0118] In Example 3, at the initial stage of crystal growth, the crucible rotation speed Ω was changed in the same manner as in Example 2, and from the midstream of growth, the crucible rotation speed Ω was fixed at the same rotation speed as in Comparative Example 1 , After that, the change of the crucible temperature T is carried out by adjusting the power supplied to the auxiliary heater 6 . In addition, Equation (5) is used in the prediction equation along with the same functions F and I used in Example 2 and the constants A, B, and E used in Example 2.

[0119] FIG. 6 shows the variation of various operating parameters (rotational speed of the crucible Ω and power supplied to the auxiliary heater 18S) and the temperature T of the crucible. Wherein the crucible rotational speed Ω and the power supplied to the auxiliary heater 18S represent the percentages of the values stated in Comparative Example 1, and the crucibl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com