Component assembling construction auxiliary apparatus in hydraulic engineering and using method thereof

An auxiliary device and hydraulic engineering technology, which is applied in hydraulic engineering, hydraulic engineering equipment, and ship lifting devices, can solve problems such as personnel injury, cumbersome operation, and unsafety, and reduce construction costs and ship machinery costs. , cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

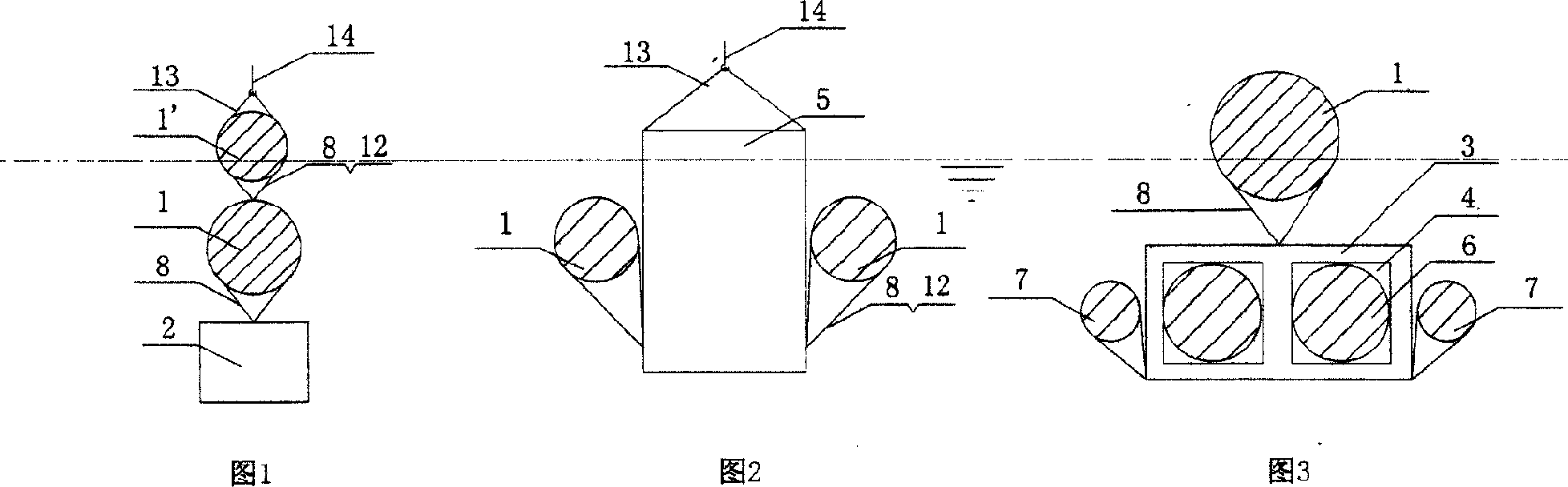

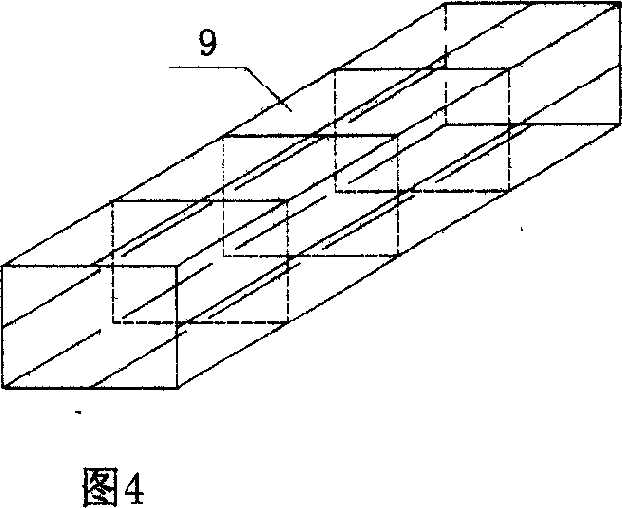

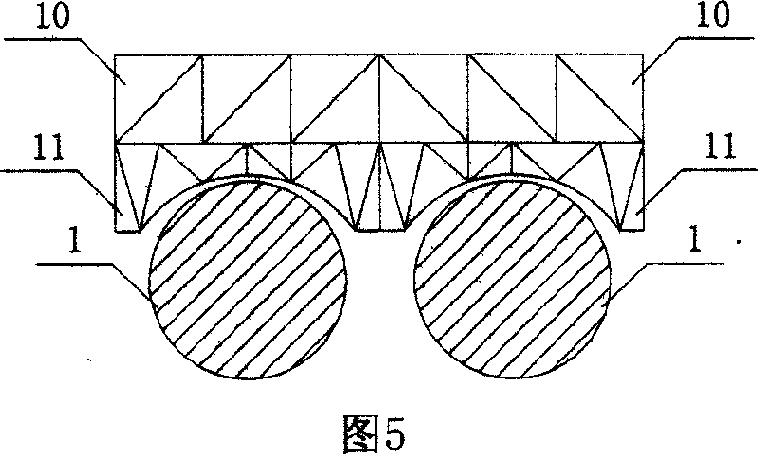

[0024] Refer to Figure 1-5 for an auxiliary device for component installation and construction in hydraulic engineering. The auxiliary device includes: at least one air bag 1 of the buoyancy aid mechanism, connecting between the air bag 1 of the buoyancy aid mechanism, or between the air bag 1 of the buoyancy aid mechanism and the component body 2 or 3, 4 Position connector 8. The auxiliary device is hung on the hook 14 of the crane or the crane (not shown in the figure) through the lifting connector 13, thereby assisting the crane or the crane to complete the hanging and floating installation of the component body 2 or 3, 4 or 5 Construction; as shown in Figure 1 and Figure 2, the up and down series airbags 1 and balloon 1' of the auxiliary device or the left and right series airbags 1 are arranged on the block body 2 or the member of the caisson 5 through the hanging net rope 12 of the positioning connector 8 On the water surface or under the water surface around the body; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com