Engine air filter discharge pipe sealing structure

An engine air filter and pipe sealing technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of increasing manufacturing costs, cumbersome manufacturing procedures, increasing the wall thickness of rubber pipes, etc., to ensure tightness and structural implementation. simple effect

Inactive Publication Date: 2007-03-21

CHONGQING CHANGAN AUTOMOBILE CO LTD

View PDF0 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For example: some use rubber, although the softness of the rubber material can meet the sealing performance of the joint, but it is not rigid enough because of its own softness when catering to the engine's rapid acceleration and deceleration conditions. Increase the wall thickness of the rubber tube

Some use engineering plastics, which have enough rigidity, but it is difficult to guarantee the sealing performance of the joints, so the method of changing the wall thickness has to be adopted, which increases the manufacturing cost

There are also rubber-plastic composite structures, although the sealing and rigidity can be taken into account, but the production process is more cumbersome

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

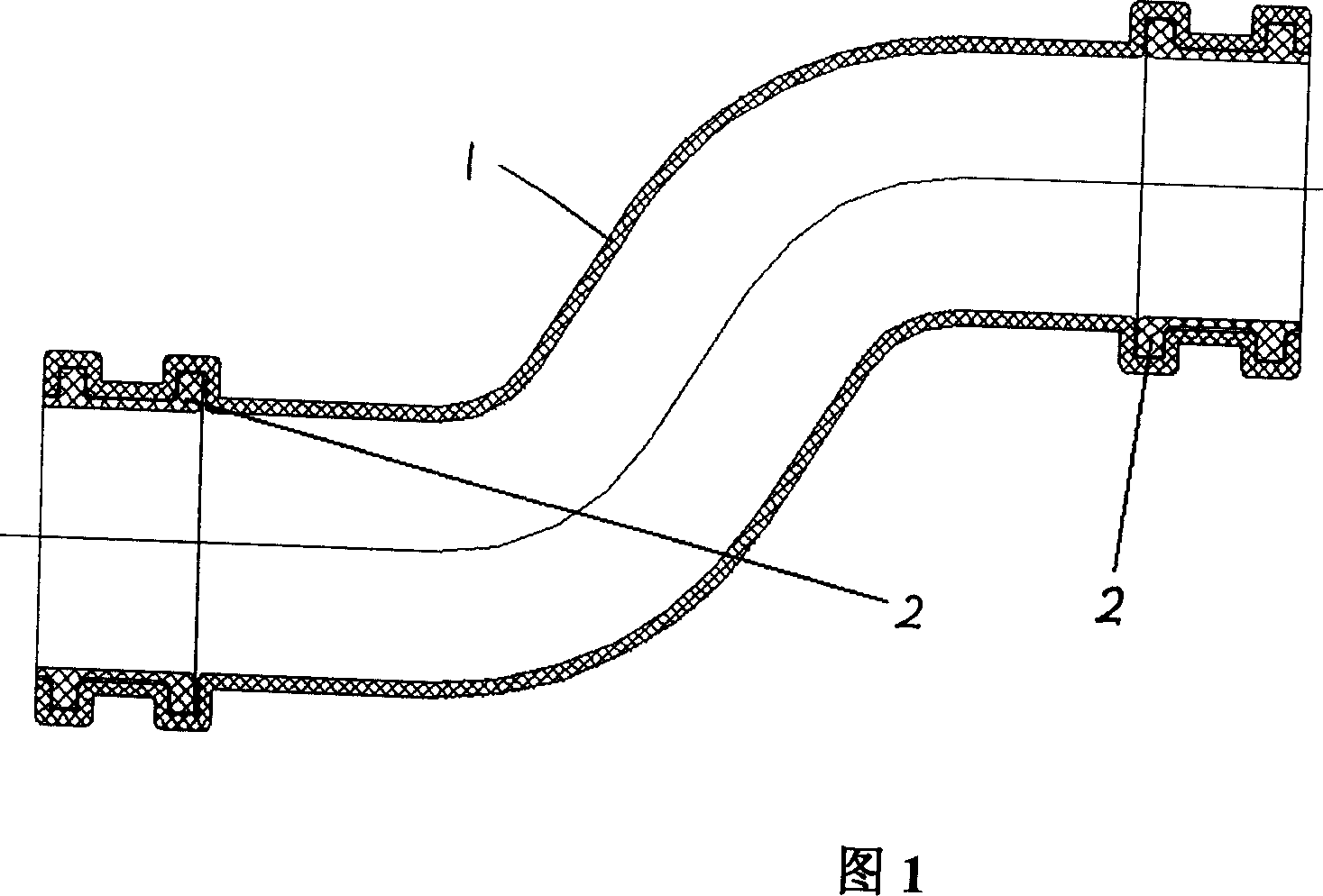

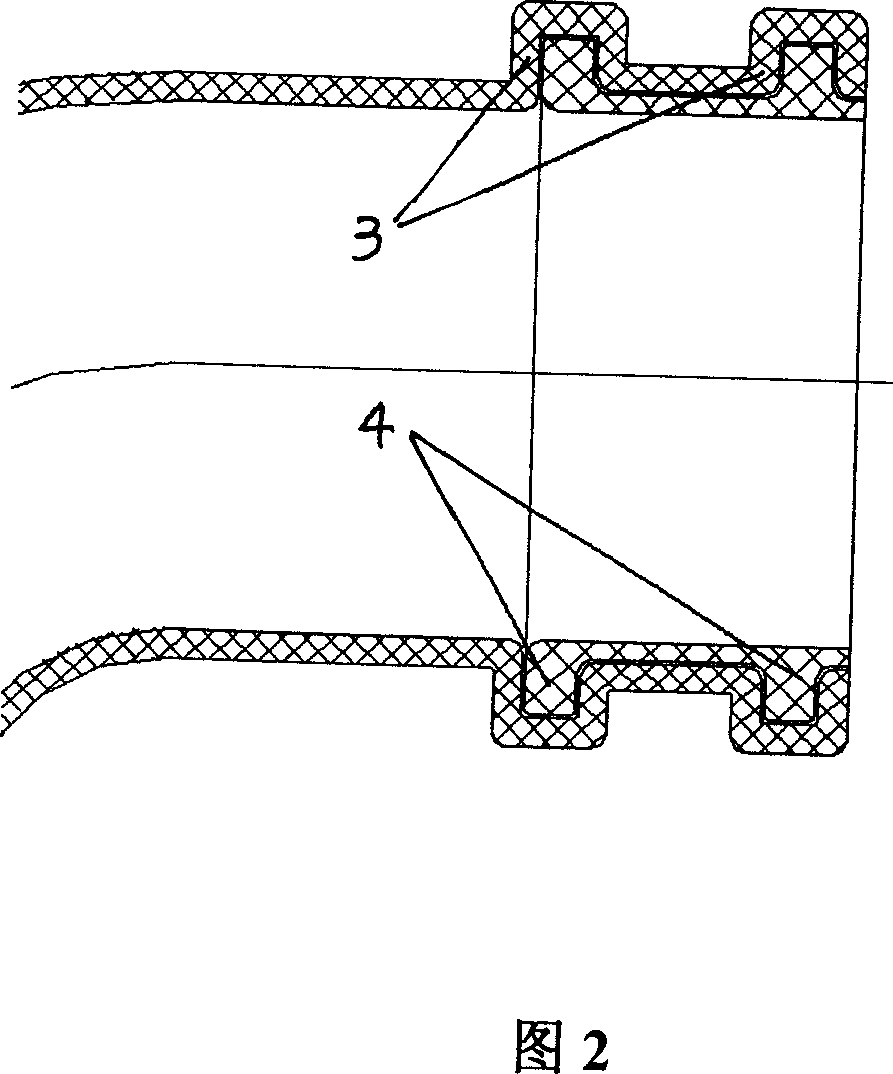

[0010] Referring to Fig. 1, this sealing structure is composed of a pipe body 1 made of engineering plastics and a rubber sealing sleeve 2. It can be seen from Fig. 2 that there are two rings of positioning grooves 3 on the inner wall of the connecting part at both ends of the pipe body 1, and the sealing rubber sleeve There are corresponding two circles of positioning protrusions 4 on the 2, which are stuck in the positioning groove 3.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The present invention relates to an air filter outlet pipe seal structure of engine. It includes pipe self-body made of engineering plastics and sealing rubber cover. On the inner walls of connecting portions of two ends of said pipe self-body several positioning grooves are cut, on the sealing rubber cover several positioning projections which are correspondent to the above-mentioned positioning grooves are set, said invention utilizes the elasticity of rubber to make the rubber cover be fastened into the positioning groove of pipe self-body, so that the pipe self-body and rubber cover can be tightly combined together so as to implement the invented seal structure.

Description

technical field [0001] The invention belongs to the technical field of engines, and in particular relates to a tube sealing structure of an engine. Background technique [0002] At present, the outlet pipe of the air filter on the car engine is mostly made of a single material. For example: some use rubber, although the softness of the rubber material can meet the sealing performance of the joint, but it is not rigid enough because of its own softness when catering to the engine's rapid acceleration and deceleration conditions. Increase the wall thickness of the rubber tube. Some use engineering plastics, which have sufficient rigidity, but the sealing performance of the joints is difficult to guarantee, so the method of changing the wall thickness has to be adopted, which increases the manufacturing cost. There is also a rubber-plastic composite structure, although the sealing and rigidity can be taken into account, but the production process is cu...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F02M35/024F16L47/00

Inventor 朱絮飞

Owner CHONGQING CHANGAN AUTOMOBILE CO LTD

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com