High-speed distributing cycloid hydraulic motor

A cycloidal hydraulic motor and flow distribution technology, which is applied in the direction of fluid pressure actuators, etc., can solve the problem that the output shaft is difficult to meet the requirements of high-precision transmission stability and high volumetric efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The present invention will be described in detail below in conjunction with the above-mentioned embodiments of the accompanying drawings.

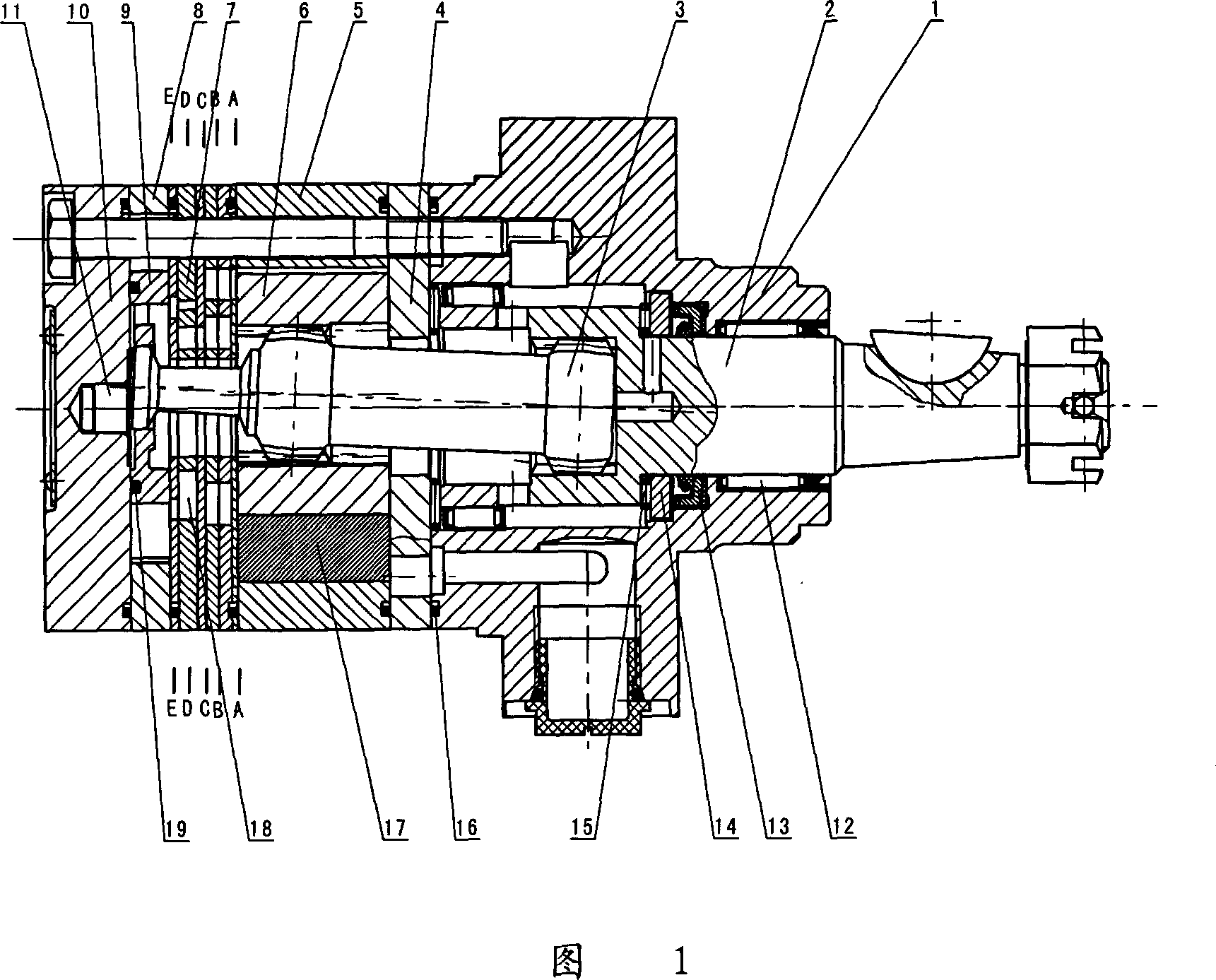

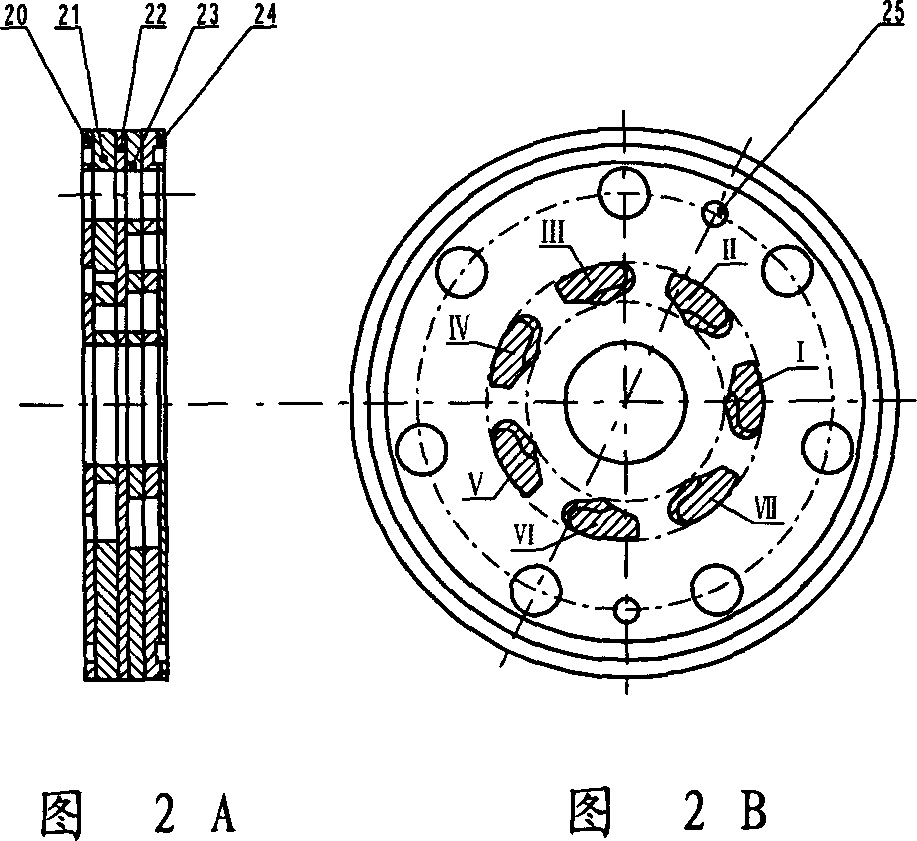

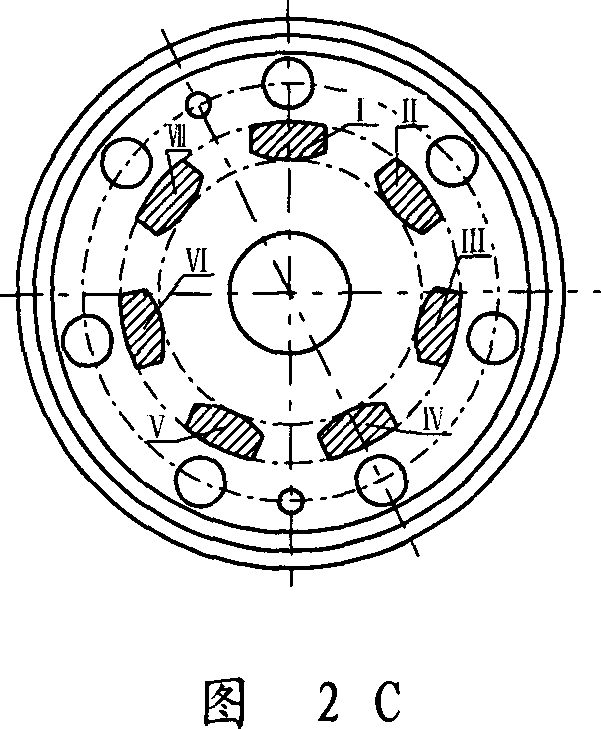

[0021] The high-speed distribution cycloidal hydraulic motor of this embodiment includes a housing 1 with a liquid inlet and a return port, and one end of the housing is fixed with a back cover 10 through a partition plate 8. A cycloidal needle composed of a stator 5 and a rotor 6 is installed. The wheel set and the distribution mechanism composed of a group of distribution support plates (see 20-24 in Figure 2) and distribution plate 9 constitute the distribution mechanism, the other end of which is against the plane of the spacer ring 14 through the needle bearing 12 and one side The thrust bearing 15 is supported by the output shaft 2 protruding from the housing, the rotor 6 of the cycloidal pin wheel pair meshes with the external gear at one end of the linkage shaft 3 through the internal spline, and the external gear at the othe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Eccentricity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com