Circuit board component thermal disassembling equipment and method

A technology for circuit boards and components, which is applied in the field of thermal disassembly equipment for circuit board components, can solve the problems of difficult temperature control, cleaning, and difficulty in maintaining a constant temperature for a long time, and achieves the effect of easy temperature control and large adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

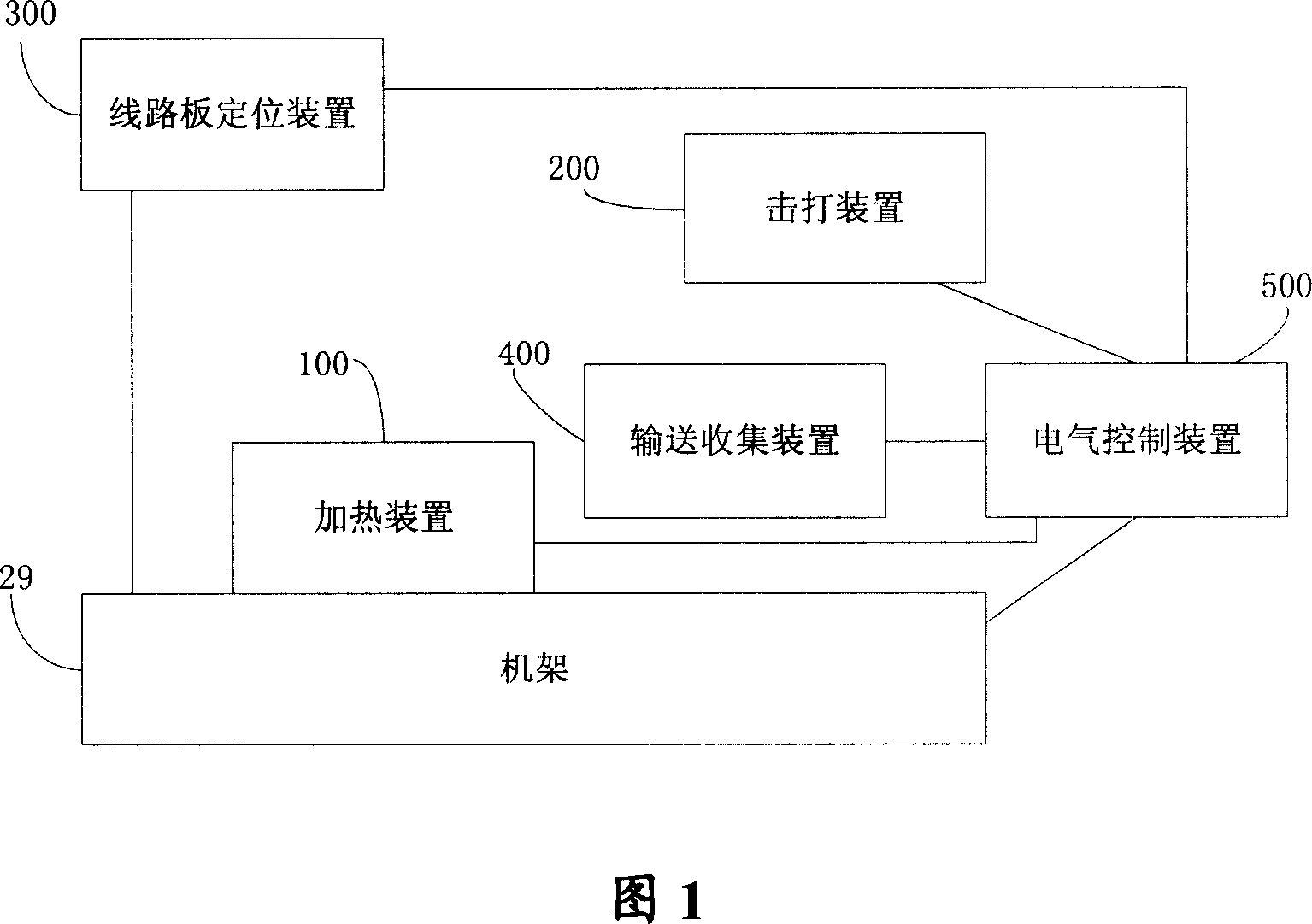

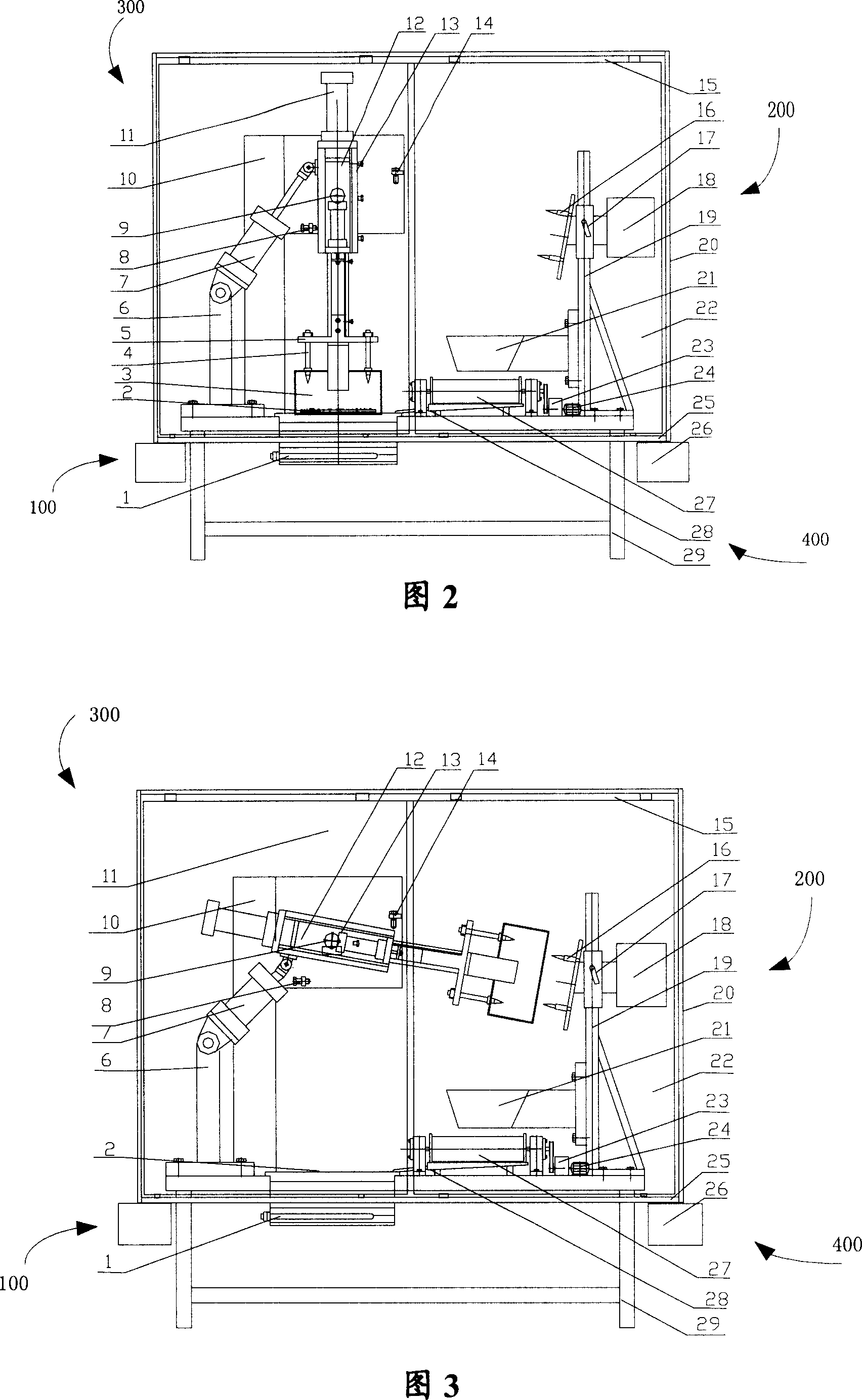

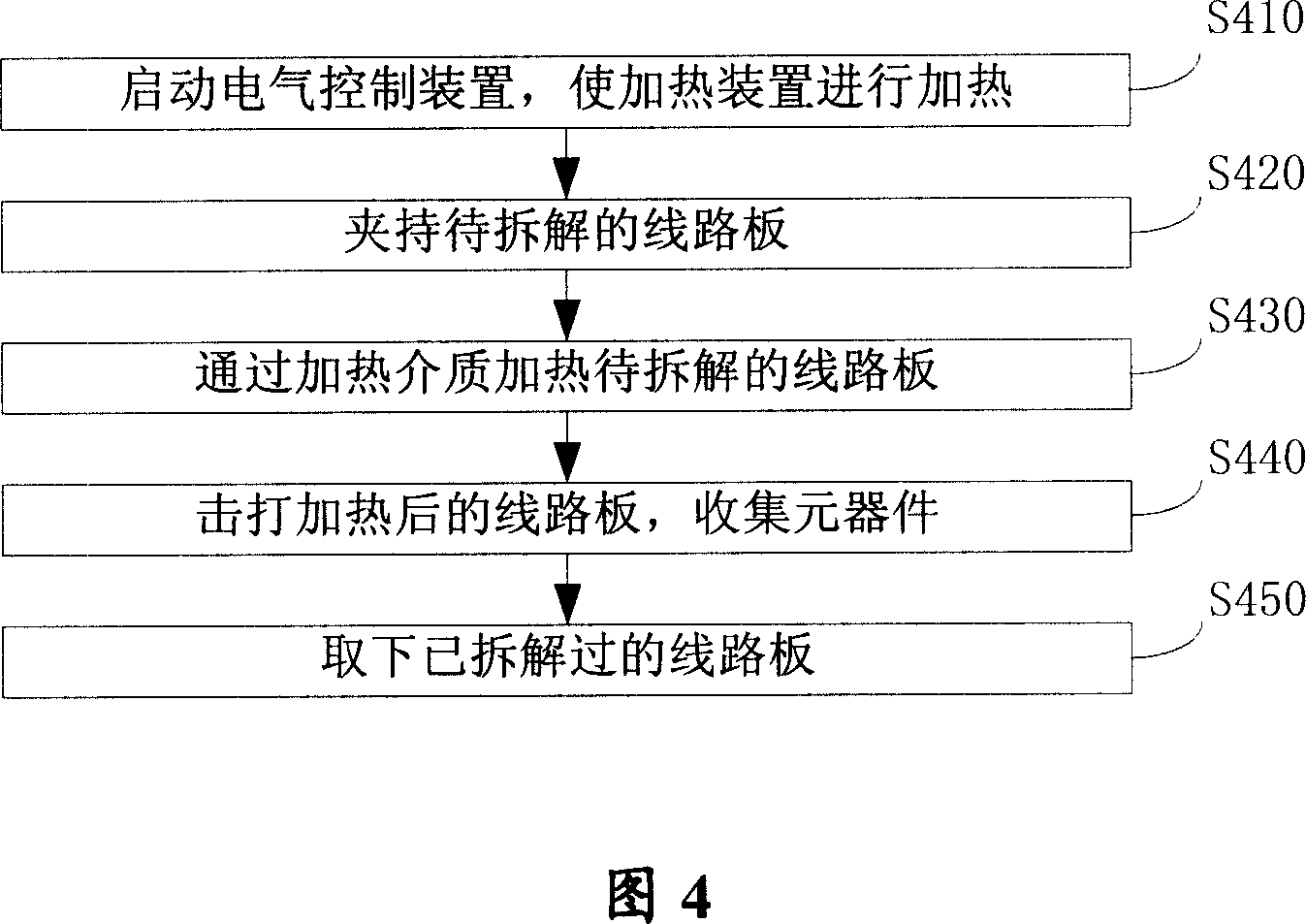

[0039] Please refer to FIG. 1 , which is a schematic diagram of the thermal disassembly equipment for circuit board components of the present invention.

[0040] The thermal disassembly equipment for circuit board components includes a frame 29 , a heating device 100 , a beating device 200 , a circuit board positioning device 300 , a conveying and collecting device 400 and an electrical control device 500 .

[0041] The frame 29 is used to provide a working platform to support and fix other devices of the thermal disassembly equipment for circuit board components, and has a certain height.

[0042] The heating device 100 is arranged on the upper surface of the frame 29 and has an accommodating space for heating medium for melting solder joints of components on the circuit board (not shown).

[0043] The beating device 200 is fixed on the frame 29 and is used for beating the heated circuit board so that the circuit board vibrates and the components fall off.

[0044] The circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com