Highpower density immersion electric heating element electric-insulating sealing device

An electric heating element, high power density technology, applied in the direction of electric heating devices, ohmic resistance heating parts, electrical components, etc., can solve the problems that are difficult to guarantee, affect the insulation seal, and the aging of the end of the resin glue insulation seal, etc., to achieve the best results Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

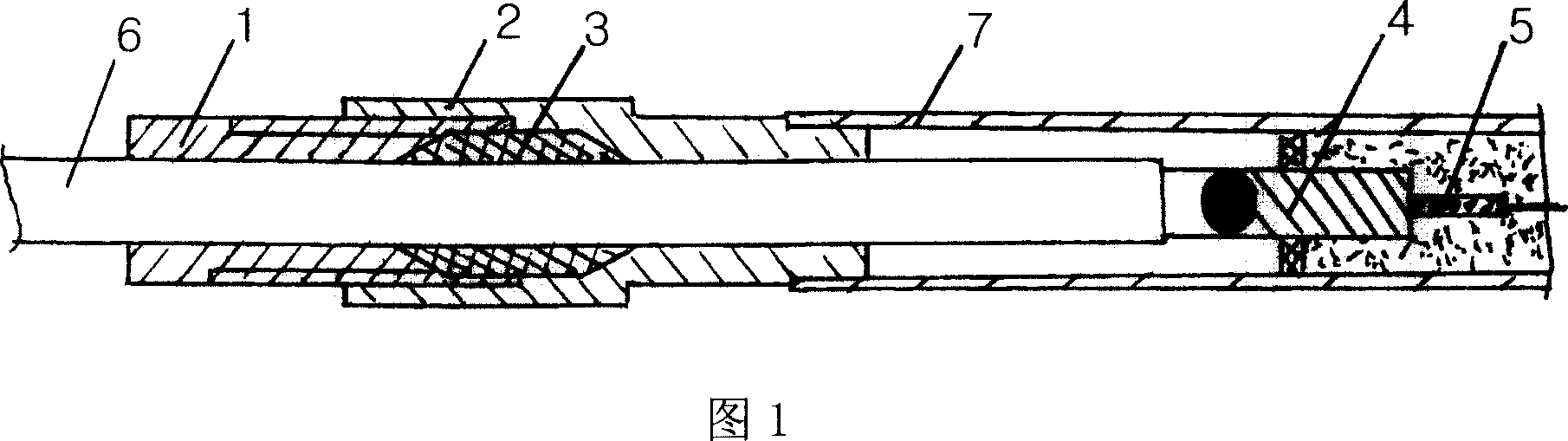

[0011] The invention provides a high power density immersion type electric heating element leading insulation and sealing device. In the structural diagram of the electric heating element lead insulation sealing device shown in Figure 1, a polytetrafluoroethylene or fluorine rubber inner ferrule 3 with two conical surfaces is placed in the sealing ferrule 2, and the inner cavity of the sealing ferrule 2 is threaded. The lower part of the section and the lower inner hole of the compression nut 1 are provided with conical surfaces matching the conical surfaces at both ends of the inner ferrule 3. When the compression nut 1 is screwed into the sealing ferrule 2, the inner ferrule 3 is compressed, and the high-temperature insulated wire 6 passes through the inner ferrule 3, and the compressed and deformed inner ferrule 3 is in sealing contact with it. Therefore, the design of the conical surfaces at both ends of the inner ferrule 3 further increases the sealing performance of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com