Panel structure and kitchen base with the same

A structure and core board technology, applied in kitchen cabinets, building structures, cabinets, etc., can solve problems such as troublesome replacement of decorative boards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

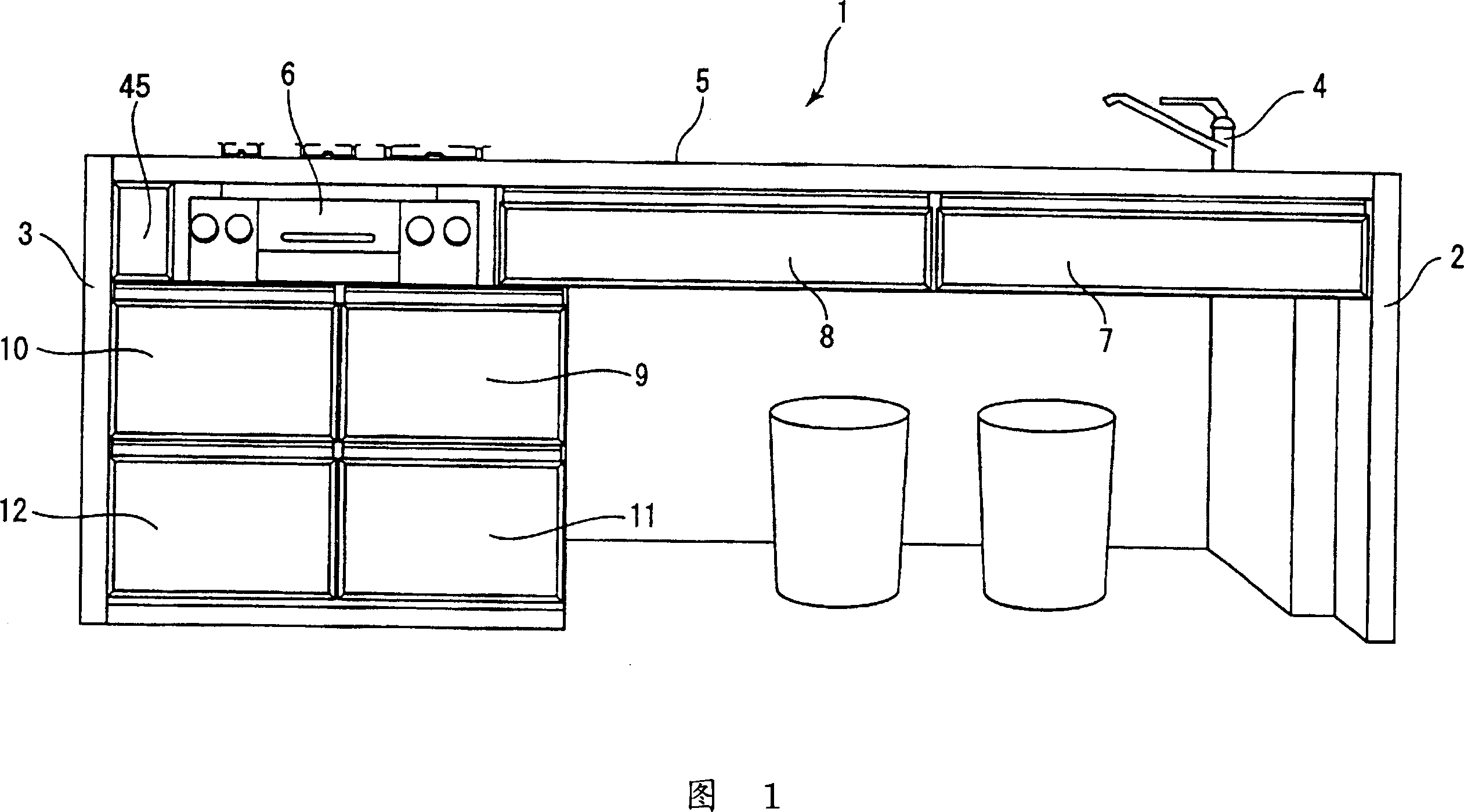

[0032] Embodiments of the present invention will be described below with reference to the drawings. First, FIG. 1 is a front view showing the overall appearance of a kitchen cabinet according to Embodiment 1 of the present invention. The reference numeral 1 in Fig. 1 is a kitchen cabinet constructed with the panel of the present invention. The kitchen cabinet 1 is provided with legs 2, 3 on the left and right, and a top 5 provided with a faucet 4, a water tank (not shown), etc. is arranged on the top of the legs 2, 3. On the lower part of the table top 5, a gas burner 6 and drawers 7 and 8 that can be drawn out to the front side are arranged side by side. In addition, below the gas stove 6, there are also four drawers 9, 10, 11, 12 that can be pulled out to the front.

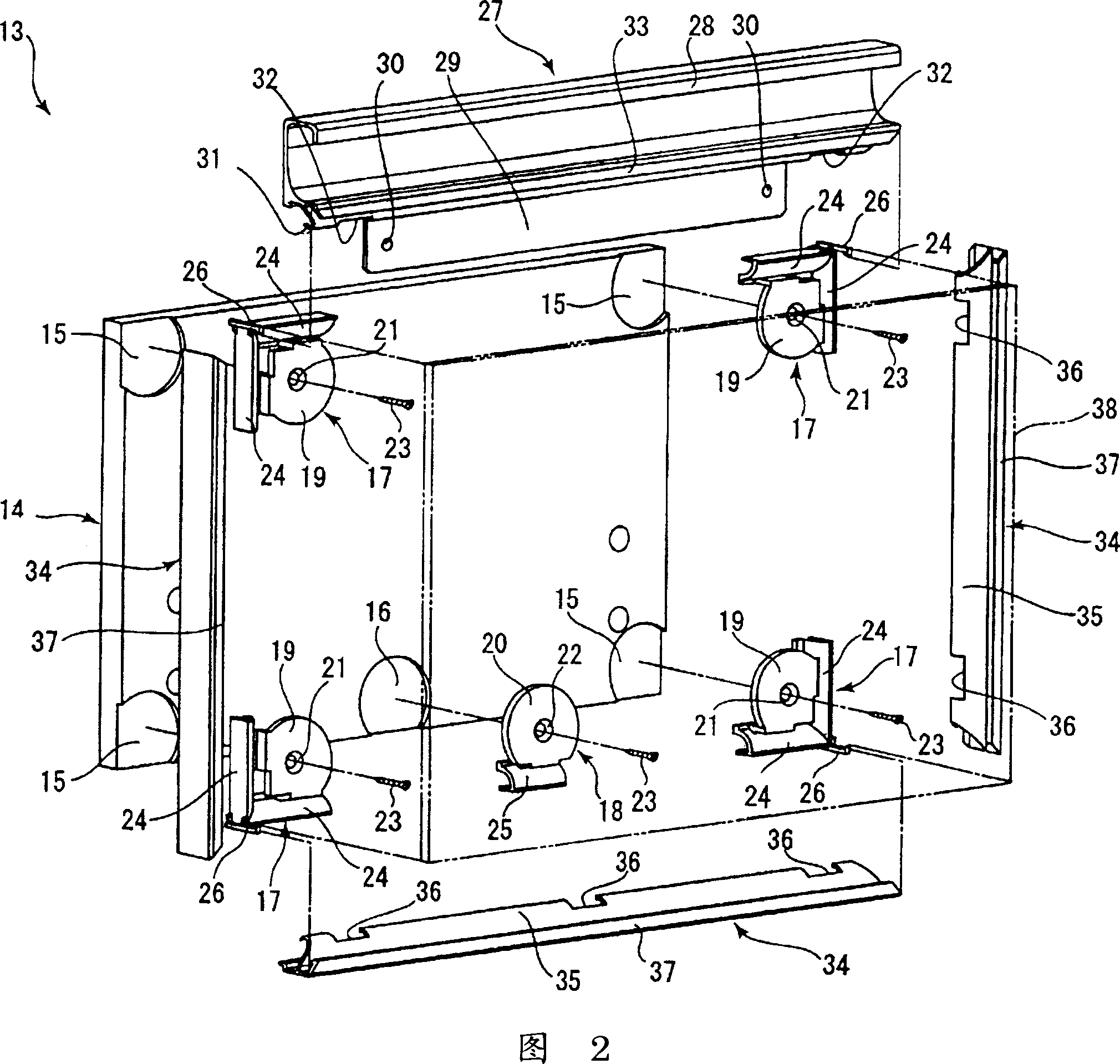

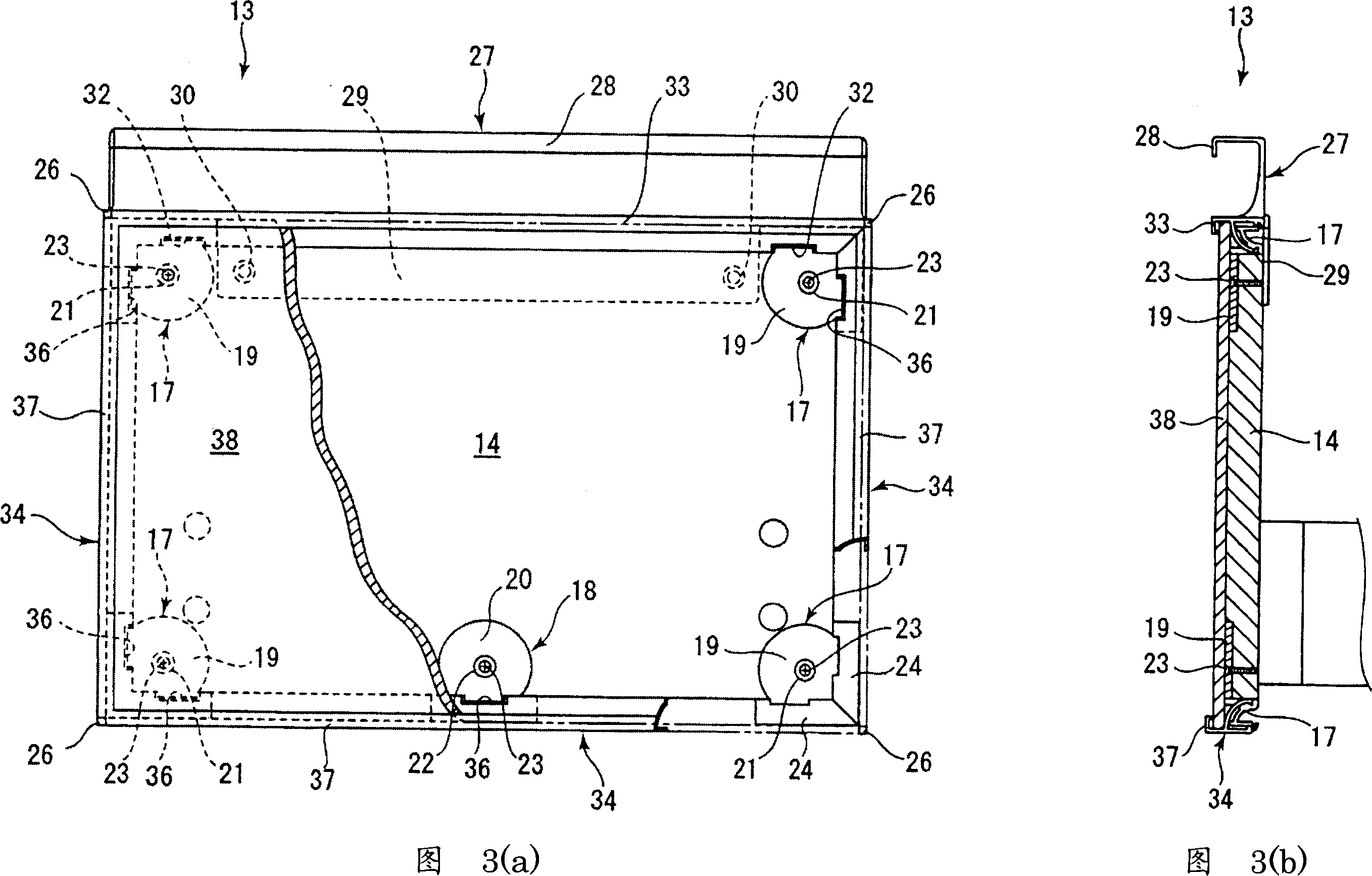

[0033] These four drawers 9, 10, 11, and 12 have the same structure, so only the drawer 9 will be described as an example. On the front side of the drawer 9, a front panel 13 having a panel structure accordi...

Embodiment 2

[0063] Next, the plate structure of Example 2 will be described with reference to FIG. 5 . Description of the same configuration as the above-mentioned embodiment is omitted.

[0064] Fig. 5 is an exploded perspective view showing the front panel 46 of the drawer according to the second embodiment of the present invention. The front panel 46 has a middle board 47 as a core board in this embodiment, and a decorative board 48 as a surface board in this embodiment is attached to the front side of the middle board 47 . Two recesses 49 are formed on the lower portion of the middle plate 47 , and a handle frame 50 is attached to the upper side of the middle plate 47 . A horizontally long handle 51 extending in the longitudinal direction is provided on the upper portion of the handle frame 50 .

[0065] As shown in Figure 5, a rectangular mounting fitting 52 extending downwards and installed on the rear side of the middle plate 47 is provided at the rear of the handle frame 50, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com