Thermoplastic resin composition and shaped body made from the composition

A technology of thermoplastic resin and composition, which is applied in the field of plastic resin composition and inclusion, and can solve problems such as reduction, poor creep resistance, resin rigidity, and insufficient impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

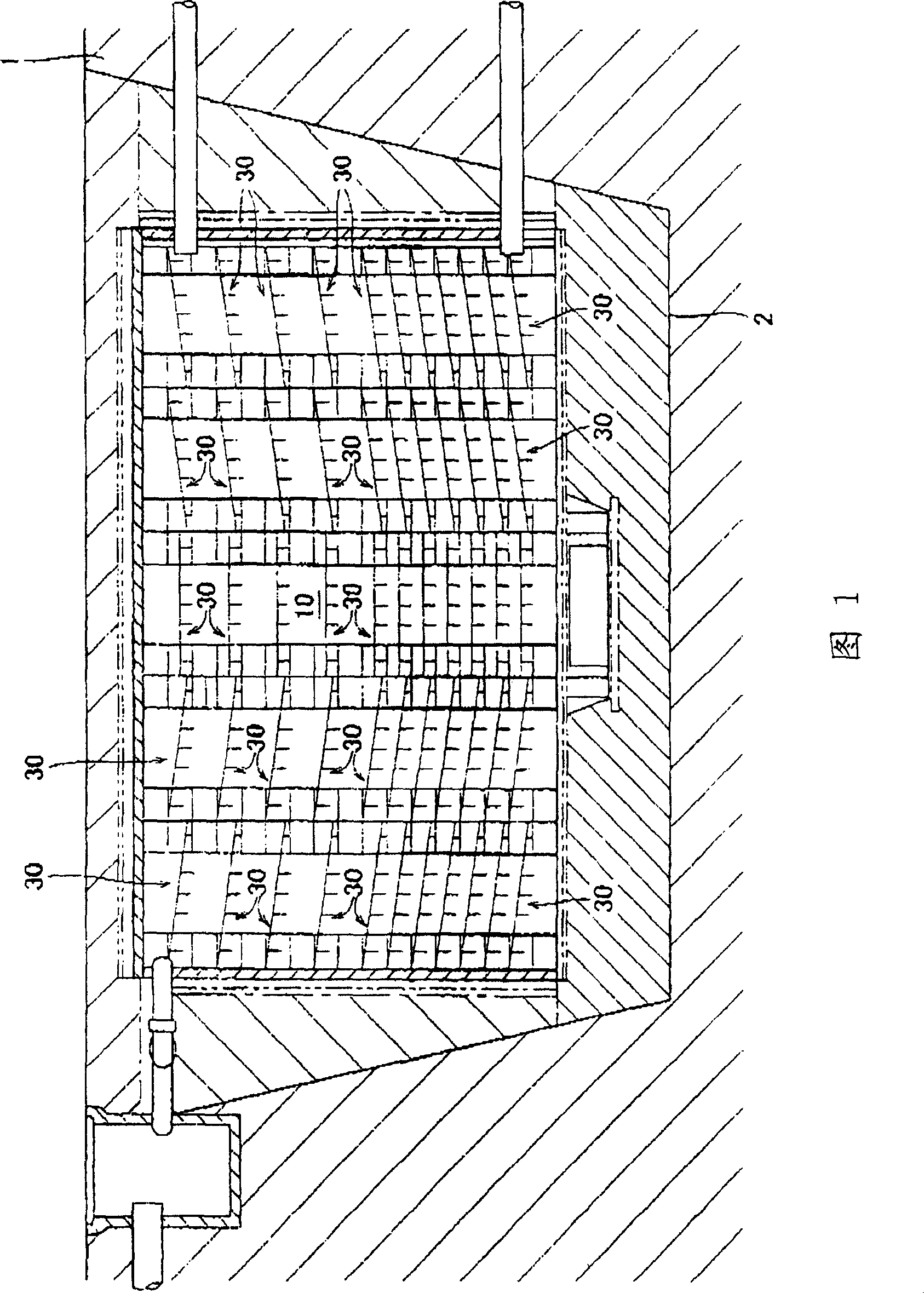

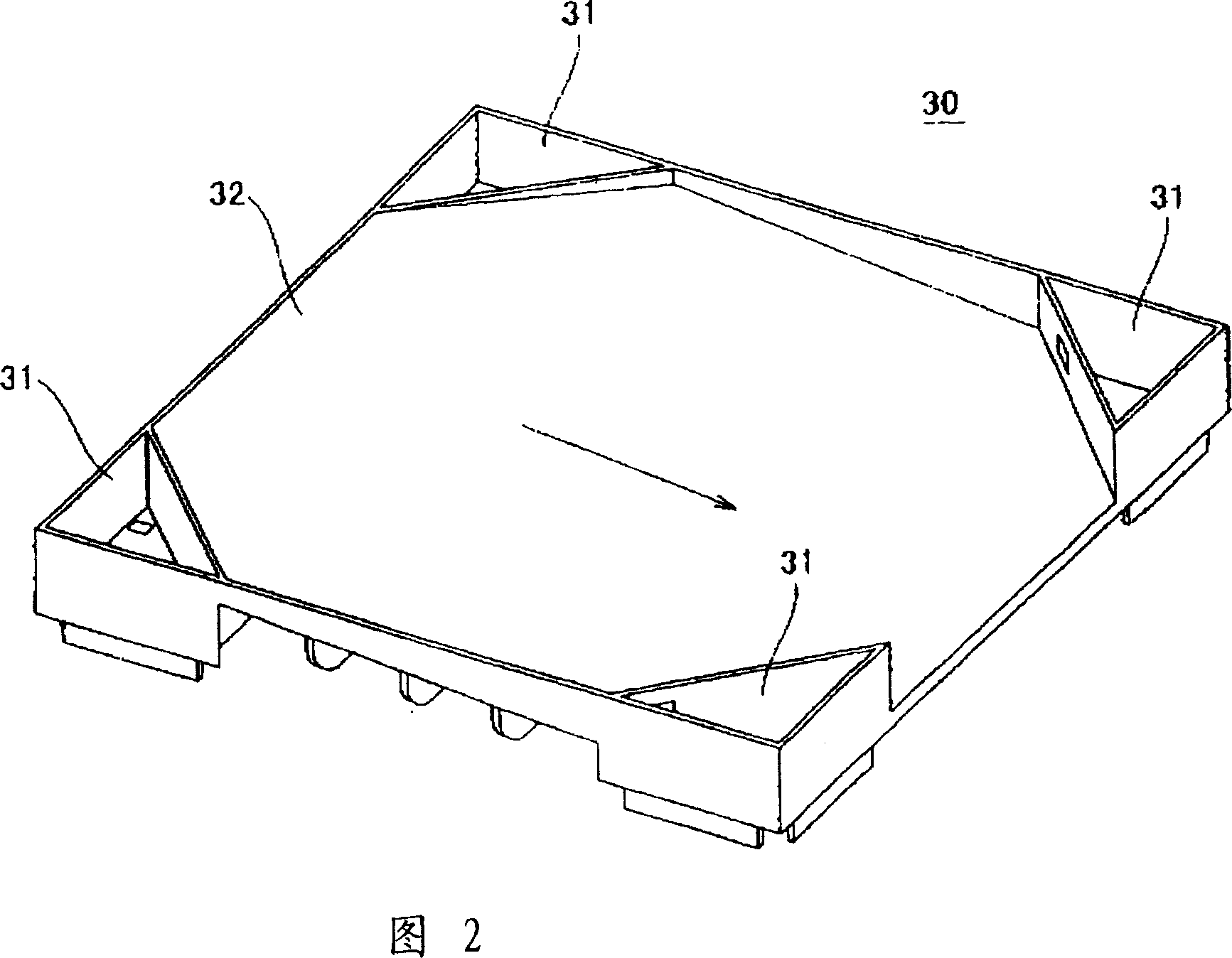

Image

Examples

Embodiment

[0075] Hereinafter, although an Example and a comparative example are shown and this invention is concretely demonstrated, this invention is not limited only to an Example.

[0076] In addition, the test methods and materials used in the examples are as follows.

[0077] 1. Test method

[0078] (1) Tensile modulus of elasticity: measured in accordance with JIS K-7162. In addition, the test piece was made into a dumbbell-shaped (Danbell) test piece using Fanatsuku Autotoshito Model 75.

[0079] (2) Maximum point stress: measured in accordance with JIS K-7162.

[0080] (3) Creep resistance: The test piece is made on the side of a rectangle with a length of 100 mm and a width of 10 mm, and two U-shaped notches of 1.5 mm are made on both sides of the central part. A load of 10 kg was applied to one end, and the time until fracture was obtained.

[0081](4) Drop weight test at 0°C: at 0°C, a 5.3R hammer was dropped on the test piece by a Dupon impact testing machine, and the he...

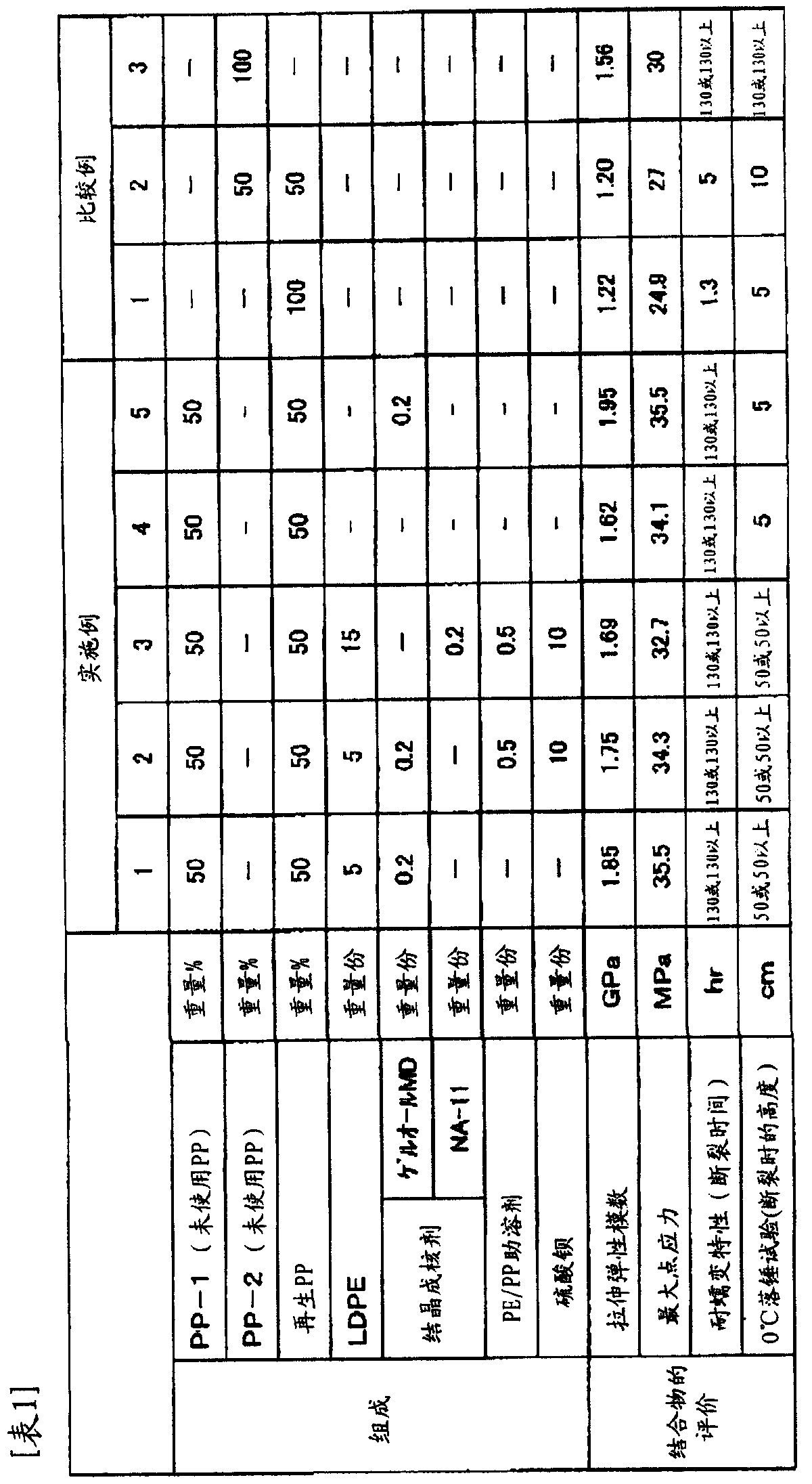

Embodiment 1~8、 comparative example 1~7

[0100] The components shown in Table 1 and Table 2 were melt-kneaded at the ratios shown in Table 1 and Table 2 using an extruder (manufactured by Plastic Engineering Research Institute Co., Ltd., model "BT-40") to obtain a recycled thermoplastic resin composition. thing. The evaluation results of the obtained compositions are shown in Tables 1 and 2.

[0101]

[0102]

[0103] As can be seen from Table 1, even if recycled raw materials are used, they can become materials with excellent mechanical properties (maximum point stress, creep resistance, impact resistance), and a large amount of recycled raw materials can be used.

[0104] In addition, as shown in Table 2, even if recycled raw materials are used, since the gel fraction becomes higher, a material with excellent mechanical properties (maximum point stress, creep resistance) can be obtained, and a large amount of recycled raw materials can be used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com