Cobalt-free anti-co 2 Poisoned high oxygen permeability biphasic oxygen permeable membrane material, preparation method and application thereof

A technology of oxygen permeable membrane and oxygen permeability, which is applied in the field of its preparation, ceramic oxygen permeable membrane, and mixed conductor oxygen permeable membrane, can solve the problems that cannot meet industrial applications, low oxygen permeability of two-phase oxygen permeable membrane, and achieve good Long-term stability, considerable oxygen permeability, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In this embodiment, a cobalt-free anti-CO 2 The preparation method of the poisoned high oxygen permeability dual-phase oxygen permeable membrane material comprises the following steps:

[0039] a. Preparation of Sm 0.1 Sr 0.9 Cu 0.2 Fe 0.8 O 3-δ Powder material:

[0040] Preparation of Sm by Sol-Gel Method 0.1 Sr 0.9 Cu 0.2 Fe 0.8 O 3-δ Powder material, first weigh 1.74g of Sm 2 O 3 In a beaker, add a small amount of concentrated HNO with a mass fraction of 68% 3 , heated with electromagnetic stirring until completely dissolved, concentrated HNO 3 The amount of addition needs to be sufficient to convert Sm 2 O 3 Completely dissolved to give Sm(NO 3 ) 3 solution; weigh 19.11g of Sr(NO 3 ) 2 , 4.84g of Cu(NO 3 ) 2 ·3H 2 O and 32.43g Fe(NO 3 ) 3 ·9H 2 O in another large beaker, add deionized water, electromagnetic stirring to completely dissolve the Sr salt, Cu salt and Fe salt to obtain an intermediate solution, and then add the prepared Sm(NO) to...

Embodiment 2

[0055] This embodiment is basically the same as the first embodiment, and the special features are:

[0056] In this embodiment, a cobalt-free anti-CO 2 The preparation method of the poisoned high oxygen permeability dual-phase oxygen permeable membrane material comprises the following steps:

[0057] a. This step is the same as the first embodiment;

[0058] b. This step is the same as that of Embodiment 1;

[0059] c. Preparation of dual-phase oxygen permeable membrane material:

[0060] Weigh Sm with a mass ratio of 5:5 0.1 Sr 0.9 Cu 0.2 Fe 0.8 O 3-δ and Ce 0.8 Sm 0.2 O 2-δ The two powders were wet ball milled for 48h with alcohol as the dispersion medium to make the two phases fully mixed evenly. Pour it into the mold, and hold it under the pressure of 180-200MPa to form a green wafer;

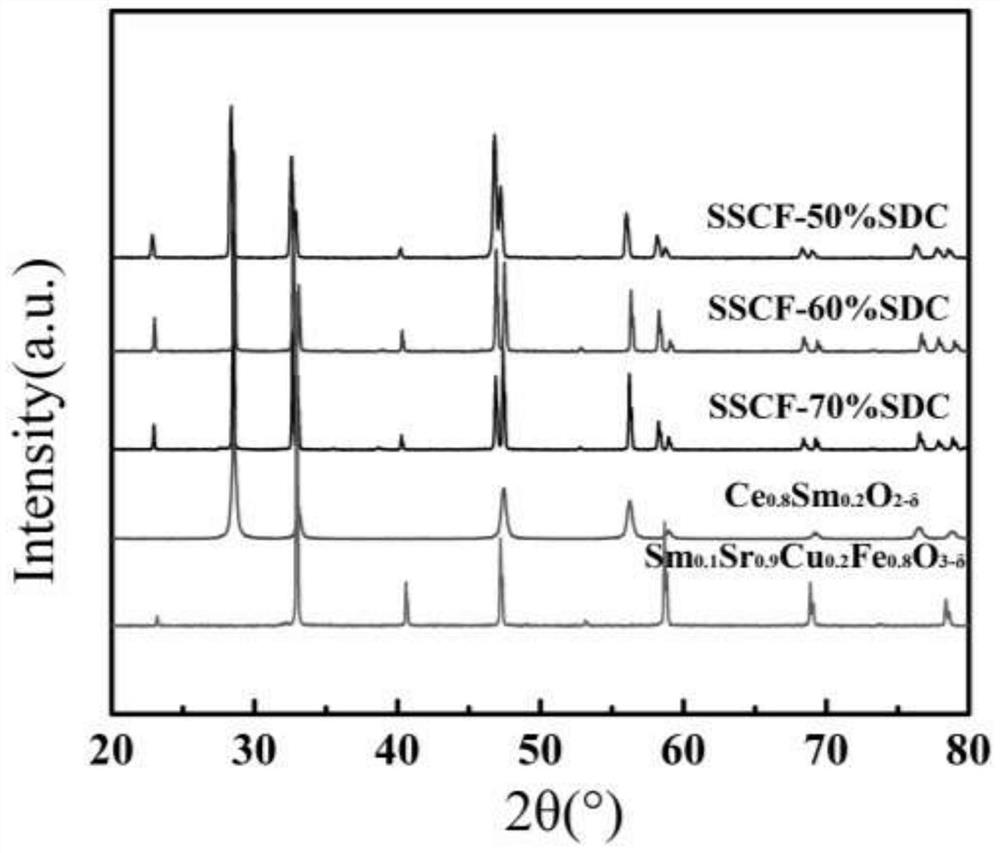

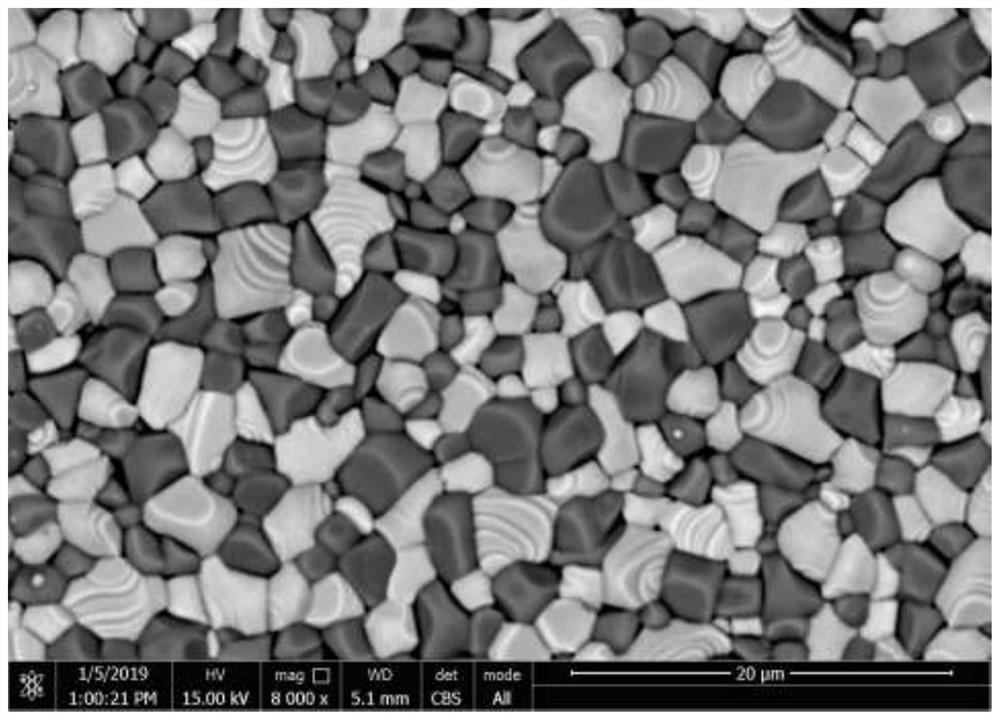

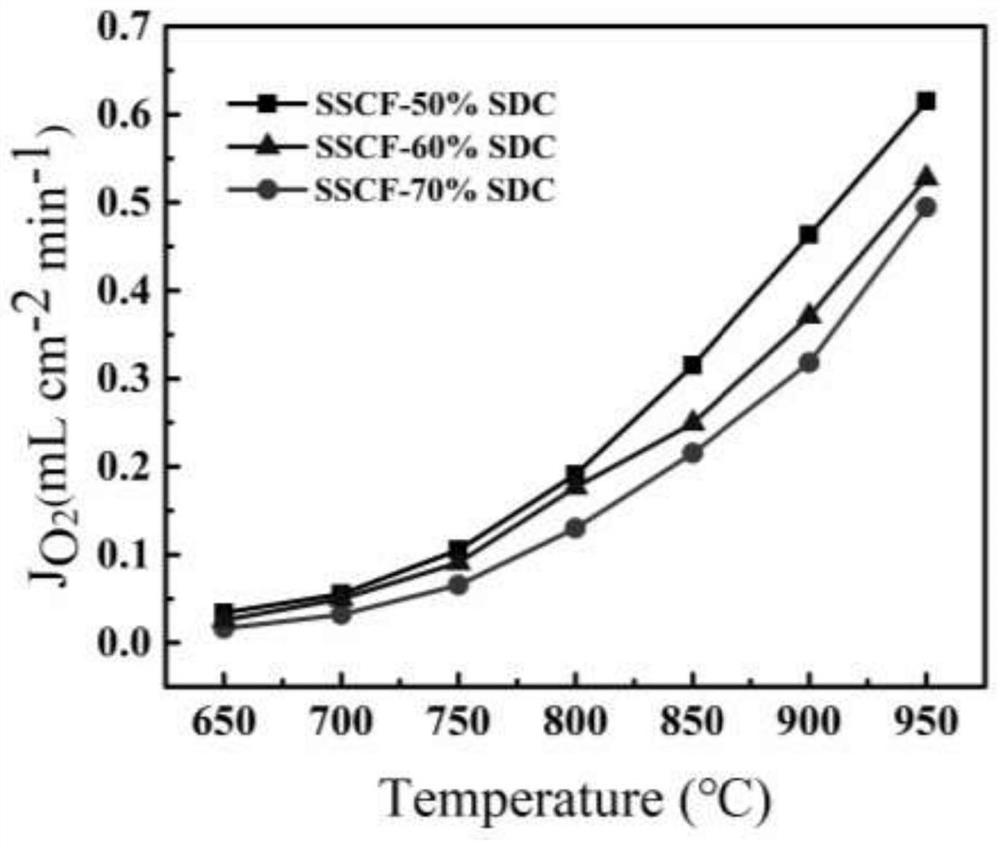

[0061] Then, the temperature was raised to 1200 °C at a heating rate of 2 K / min, and calcined for 5 h to obtain dense Sm 0.1 Sr 0.9 Cu 0.2 Fe 0.8 O 3-δ -50% Ce 0.8 Sm 0....

Embodiment 3

[0065] This embodiment is basically the same as the previous embodiment, and the special features are:

[0066] In this embodiment, a cobalt-free anti-CO 2 The preparation method of the poisoned high oxygen permeability dual-phase oxygen permeable membrane material comprises the following steps:

[0067] a. This step is the same as the first embodiment;

[0068] b. This step is the same as that of Embodiment 1;

[0069] c. Preparation of dual-phase oxygen permeable membrane material:

[0070] Weigh Sm with a mass ratio of 4:6 0.1 Sr 0.9 Cu 0.2 Fe 0.8 O 3-δ and Ce 0.8 Sm 0.2 O 2-δ The two powders were wet ball milled for 48h with alcohol as the dispersion medium to make the two phases fully mixed evenly. Pour it into the mold, and hold it under the pressure of 180-200MPa to form a green wafer;

[0071] Then, the temperature was raised to 1200 °C at a heating rate of 2 K / min, and calcined for 5 h to obtain dense Sm 0.1 Sr 0.9 Cu 0.2 Fe 0.8 O 3-δ -60% Ce 0.8 Sm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com