Branch pipe intersecting line laying out instrument

A technology of intersecting lines and pay-off instruments, which is applied to workshop equipment, manufacturing tools, etc., can solve problems such as the same or similar literature reports that have not been found, and achieve the effects of improving line drawing efficiency, high line drawing accuracy, and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

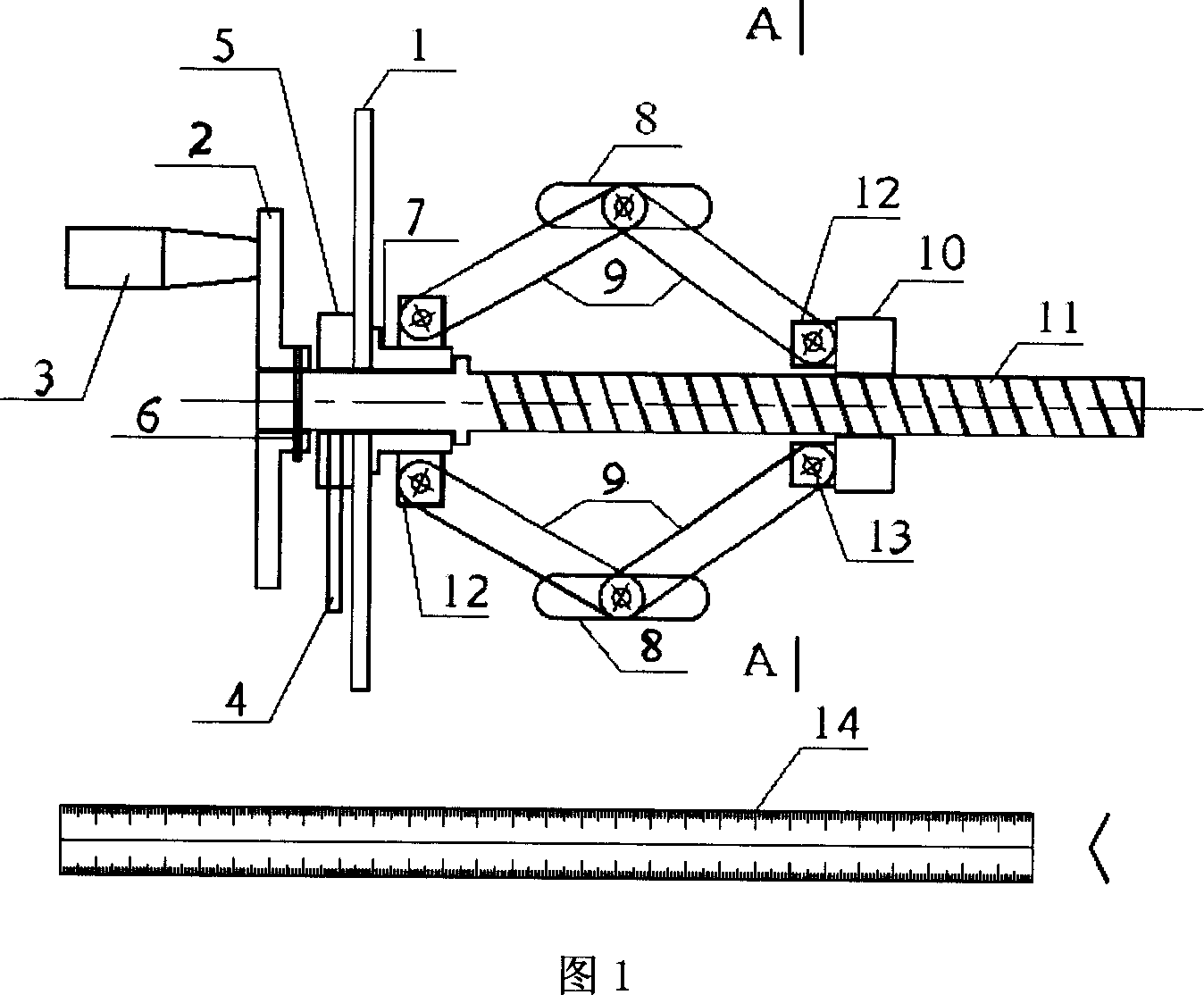

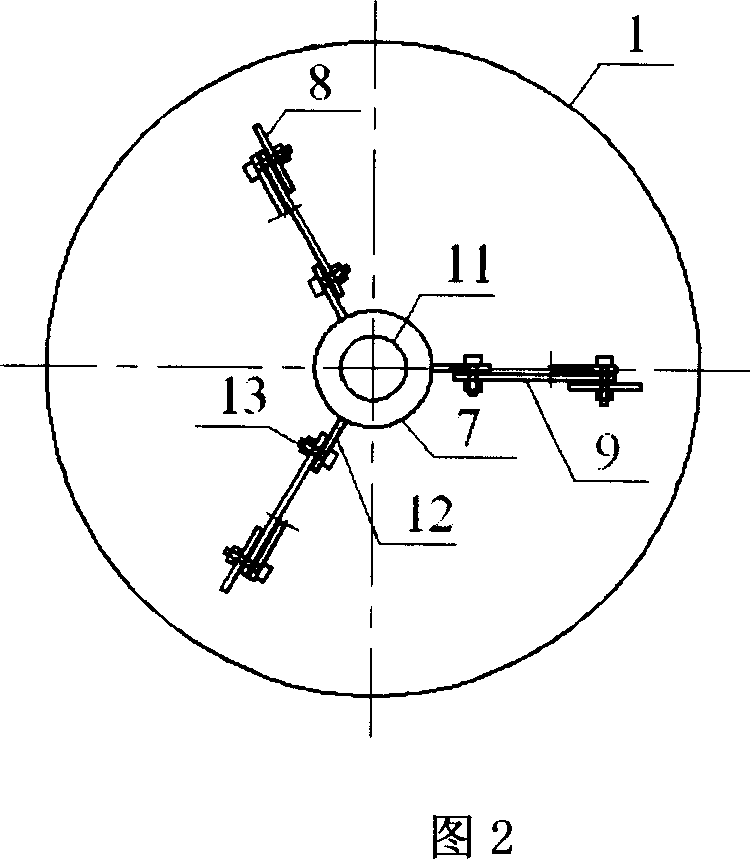

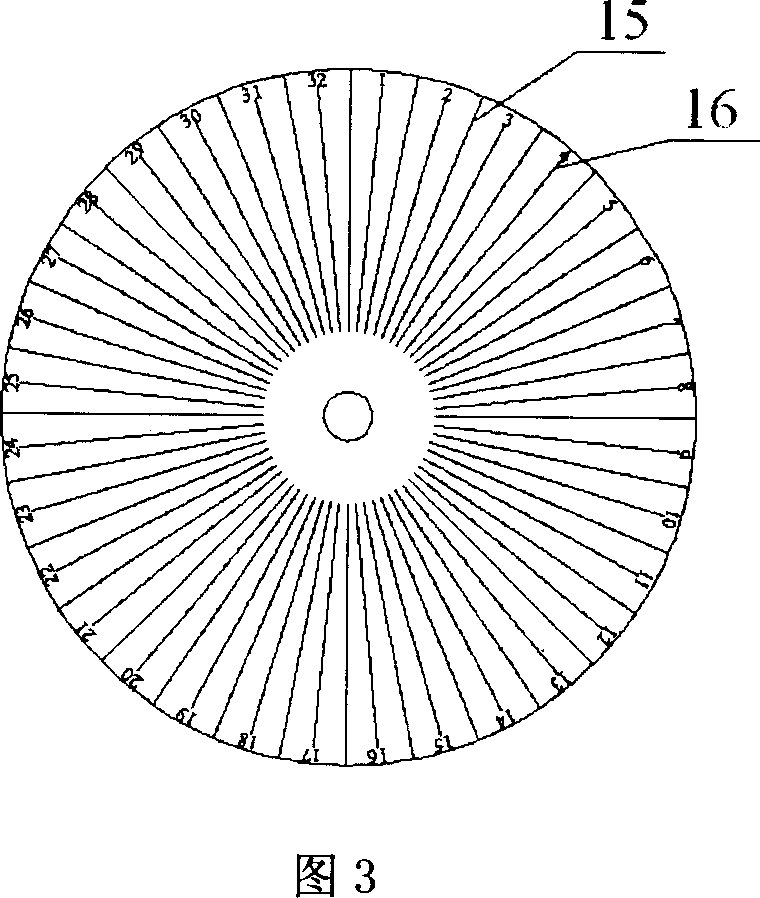

[0015] As shown in Figure 1-3, this embodiment consists of a dial 1, a rotating disc 2, a rotating handle 3, a fastening bolt 4, a fixed block 5, a fixed bolt 6, a fixed nut 7, three positioning steel sheets 8, three sets of Connecting rod 9, movable nut 10, central shaft 11 and steel ruler 14 form. The dial 1 is connected with the fixed block 5 and the fixed nut 7, the central shaft 11 is inserted into the central hole of the dial 1, the fixed block 5 and the fixed nut 7, and then the central shaft 11 is inserted into the rotating disc 2, and the rotating disc 2 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com