Biosensor

A biosensor and substrate technology, applied in subcutaneous biometrics, biometric identification, instruments, etc., can solve the problems of capacitive fingerprint sensor being easily affected by electrostatic discharge, difficult to obtain clear directionality, and low light receiving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

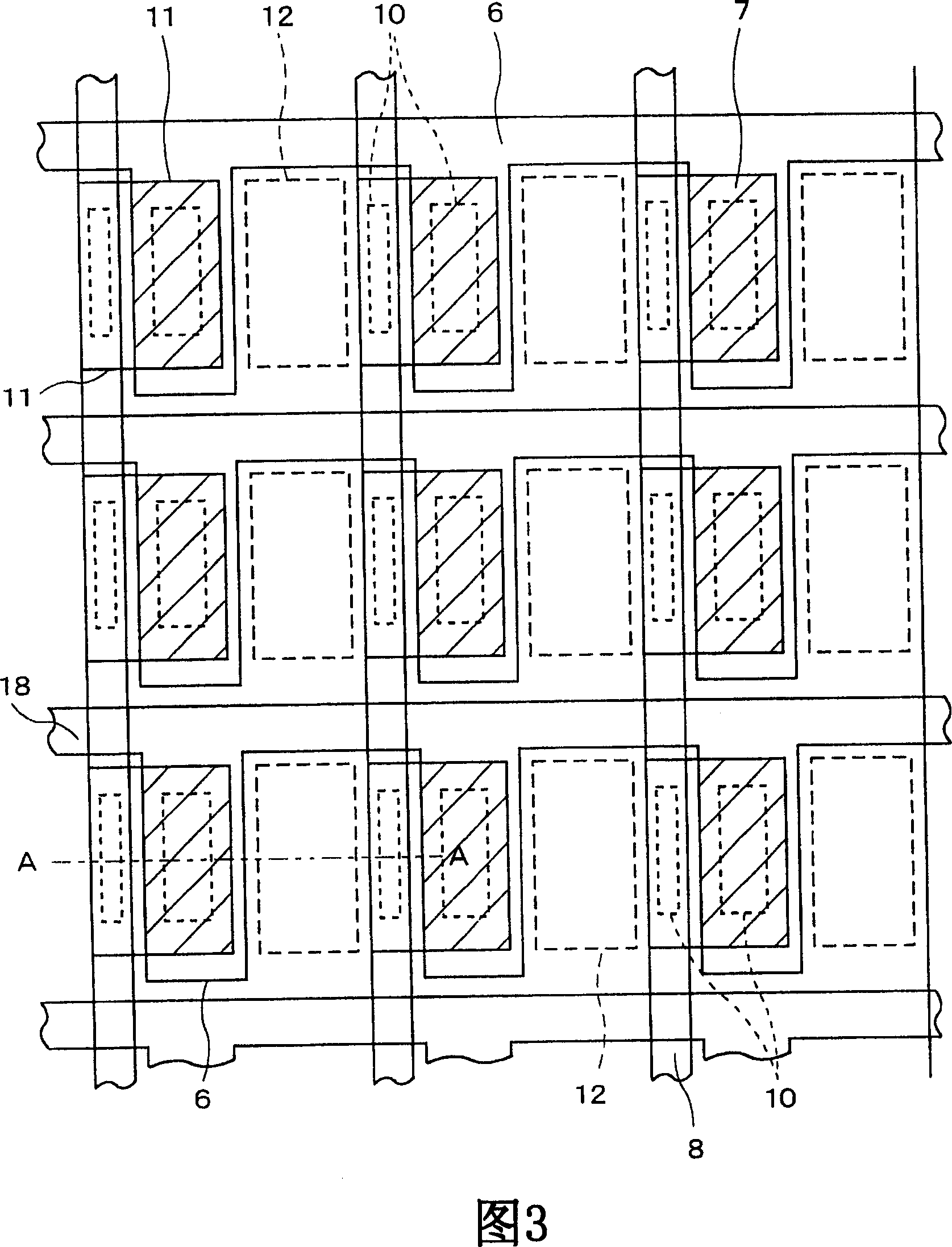

[0023] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings. 3 shows a plan view of a unit for detecting fingerprints or veins in the biosensor according to the present embodiment, and FIG. 4 is a longitudinal sectional view along line A-A shown in FIG. 3 .

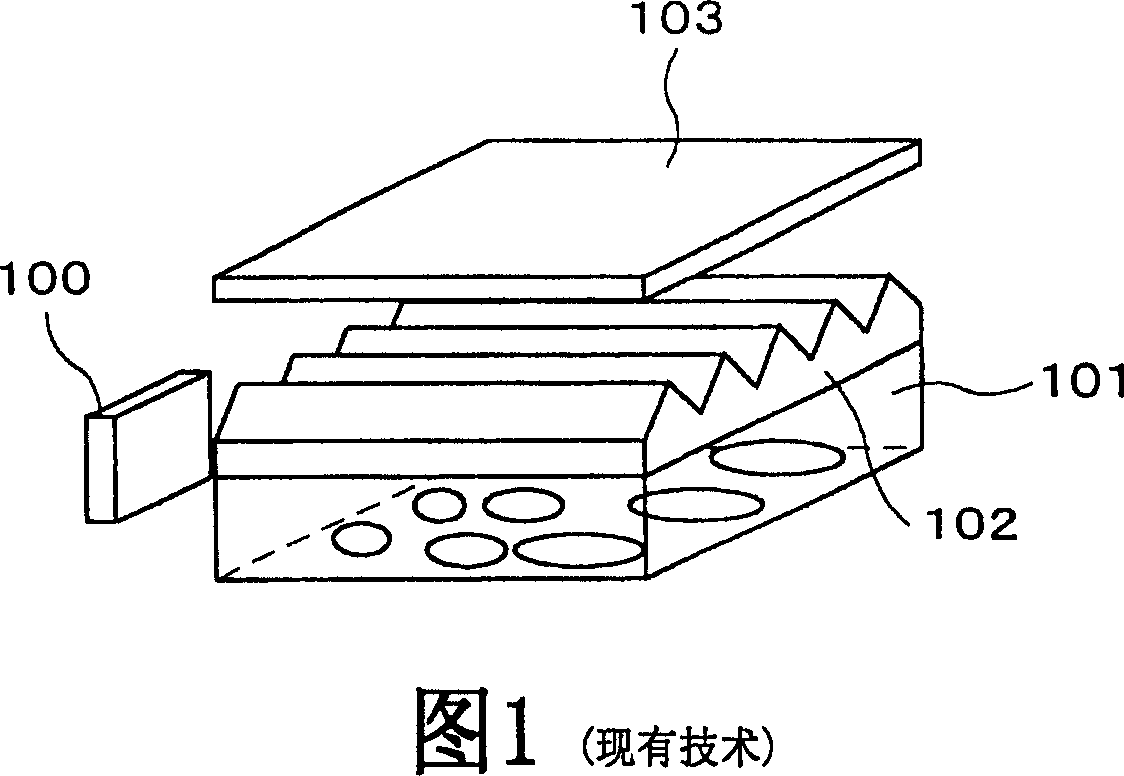

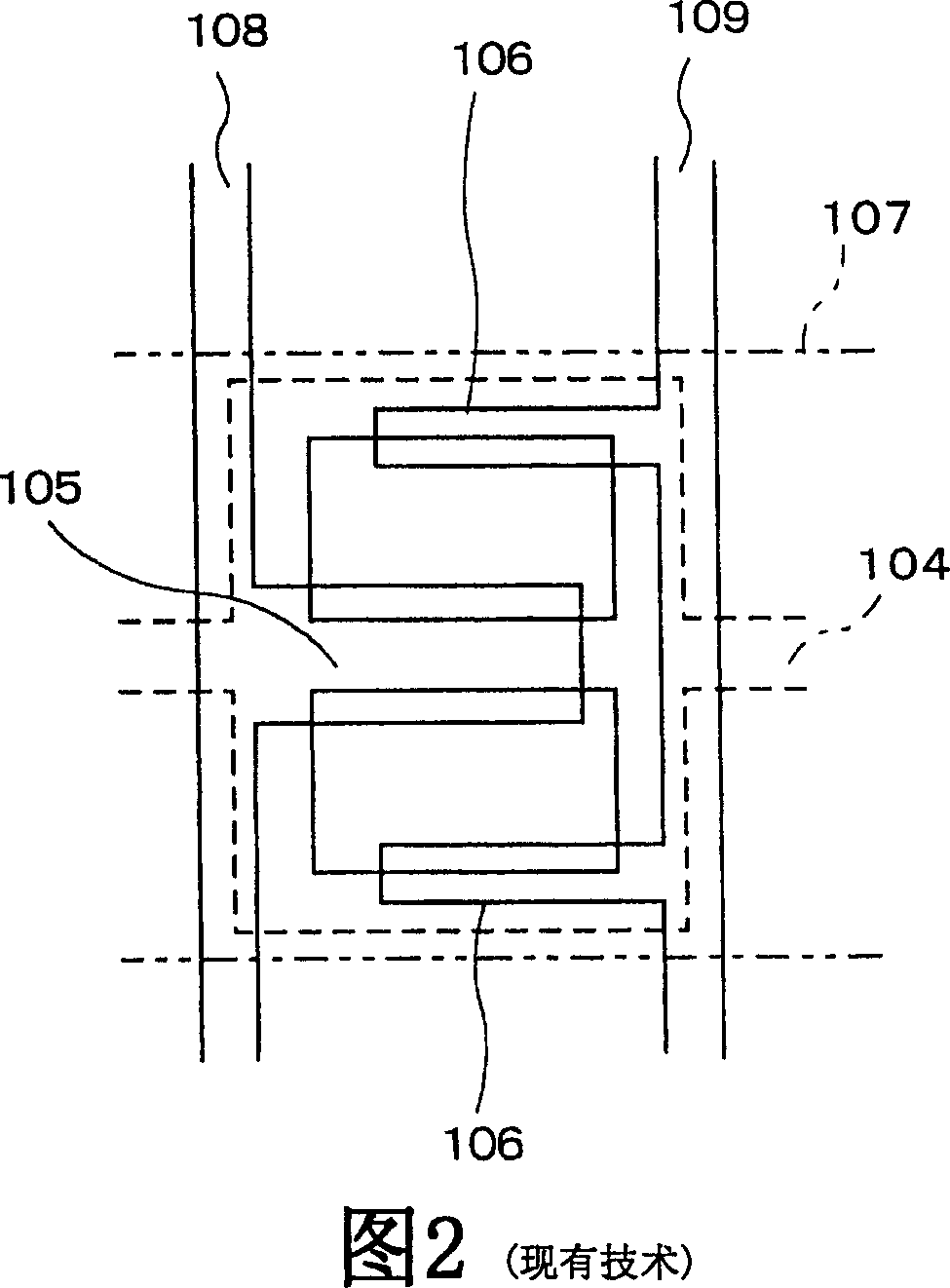

[0024] As shown in FIG. 4, for example, a louver 2 is placed on a backlight unit 1 composed of LEDs (Light Emitting Diodes). For example, the louver 2 is a louver film having a thickness of about 300 μm, which is composed of a film in which transparent portions and opaque portions are laminated in an alternate manner. A light-receiving substrate is also placed on the louver 2 . In this light-receiving substrate, a sensor element is formed on a transparent insulating substrate 3 composed of, for example, glass. Specifically, an opaque film 4 having an opening 12 is formed on the substrate 3 , a transparent insulating film 5 is formed on the opaque film ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap