Wind turbine blade

A technology of wind turbine blades and blades, which is applied in the direction of wind engines, engines, and wind engines in the same direction as the wind, so as to achieve the effect of optimizing logistics and reducing assembly time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] For wind turbine blades that are subdivided transversely into modules, the first question that arises is how many modules the blade should be divided into depending on various factors, among them means of manufacture, transport feasibility Sex etc. can be taken into consideration. For example, the blade may be subdivided into three modules, however, depending on other factors, it may also be decided to subdivide it into a greater number of modules of shorter length, or into a smaller number of modules of Longer modules.

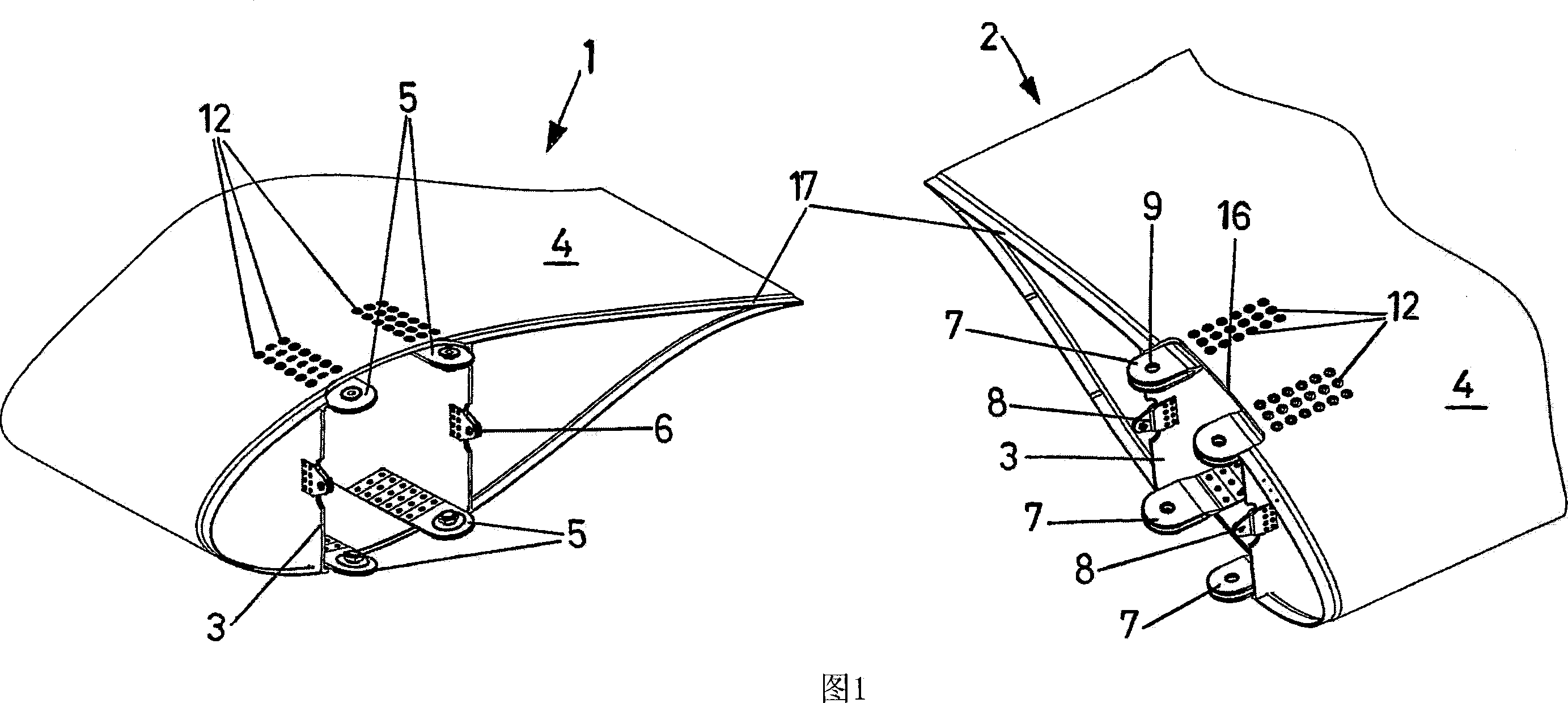

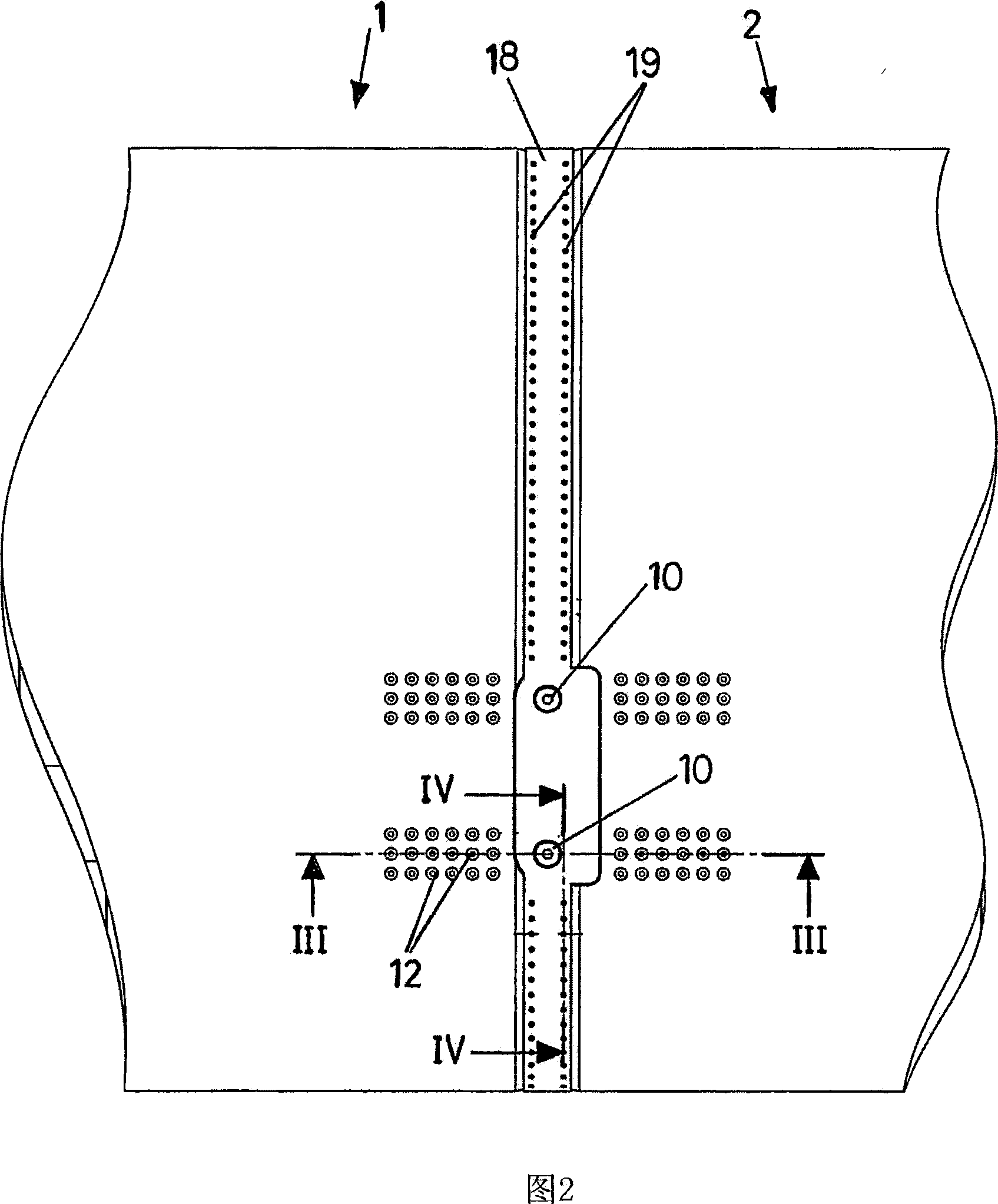

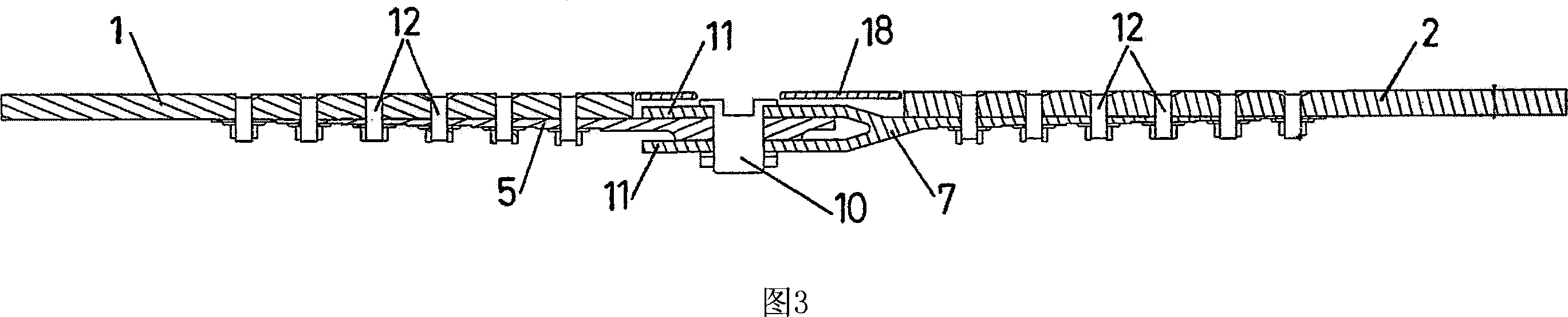

[0034] Figure 1 shows a perspective view of the faceable end segments of two consecutive modules 1 and 2 of a wind turbine blade. These blades consist essentially of internal stiffening structural members and an aerodynamic shell or box 4 attached to a beam 3, either of which may be constructed of a fiber reinforced resin of a different nature, in the described embodiment, the Internal reinforcement structural members take the form of structural beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com