Wheel holder of scriber

A technology of wheel holder and scriber, which is applied in glass manufacturing equipment, glass cutting equipment, glass production, etc., and can solve problems such as increased head load, increased head distance, and difficulty in accurately controlling the head

Active Publication Date: 2007-05-09

TOP ENG CO LTD

View PDF2 Cites 21 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in the case of using a sleeve chuck, the addition of the sleeve chuck increases the load on

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

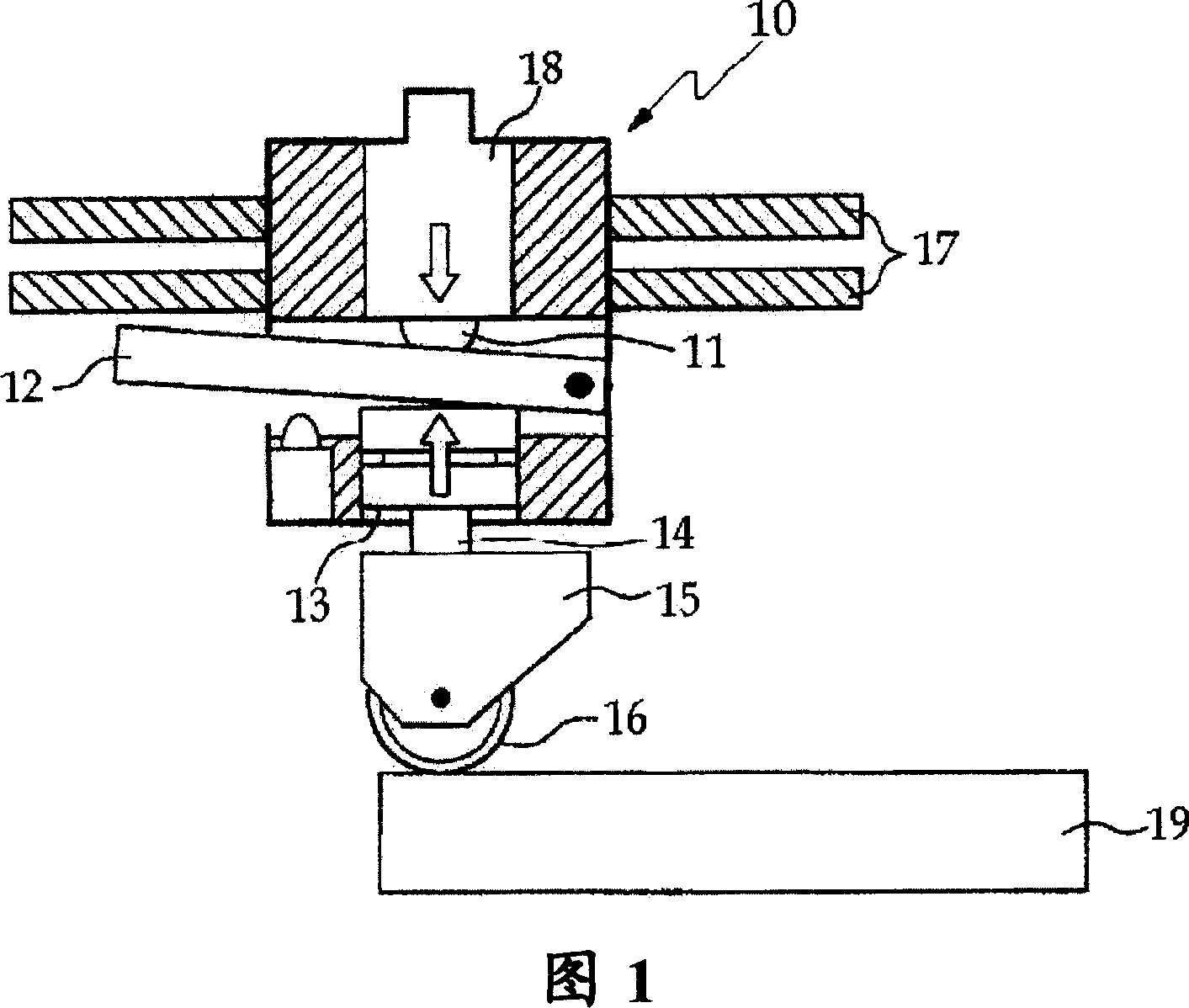

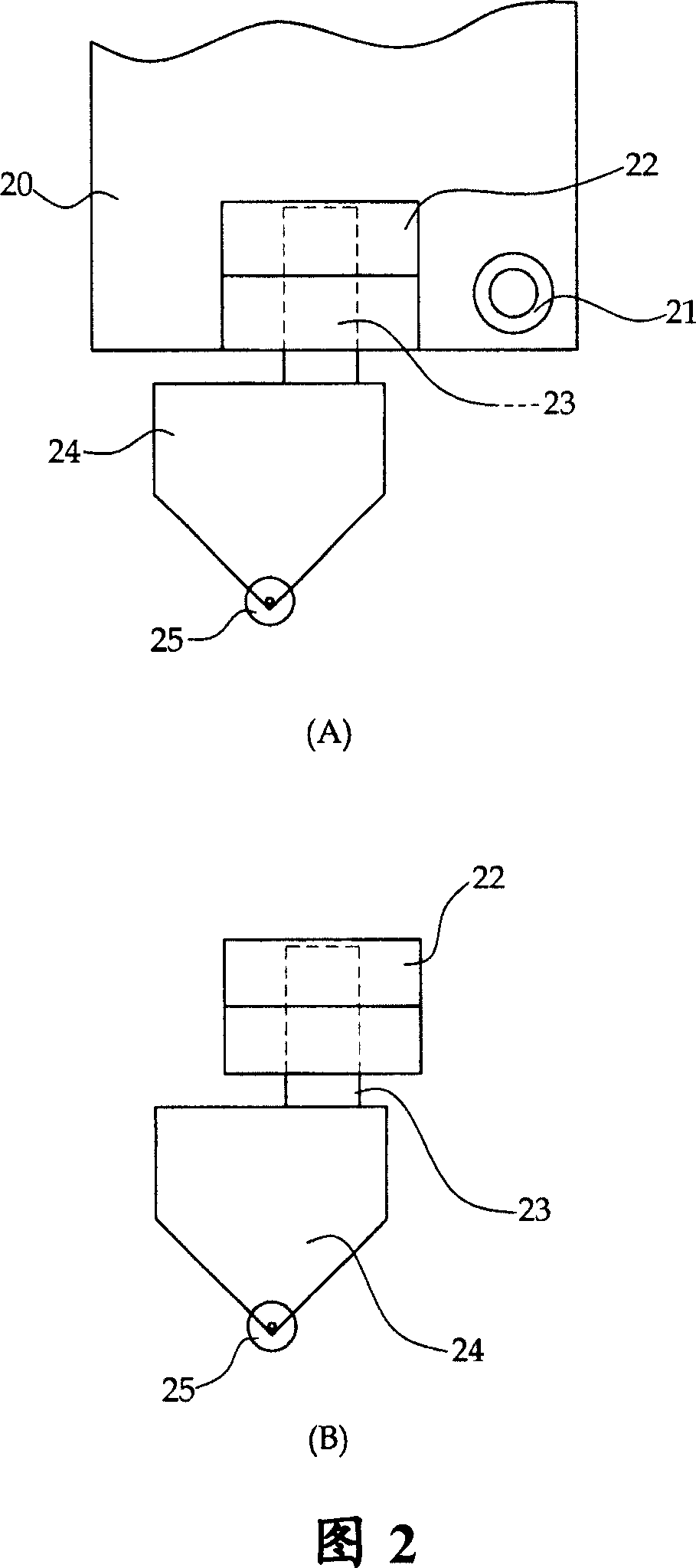

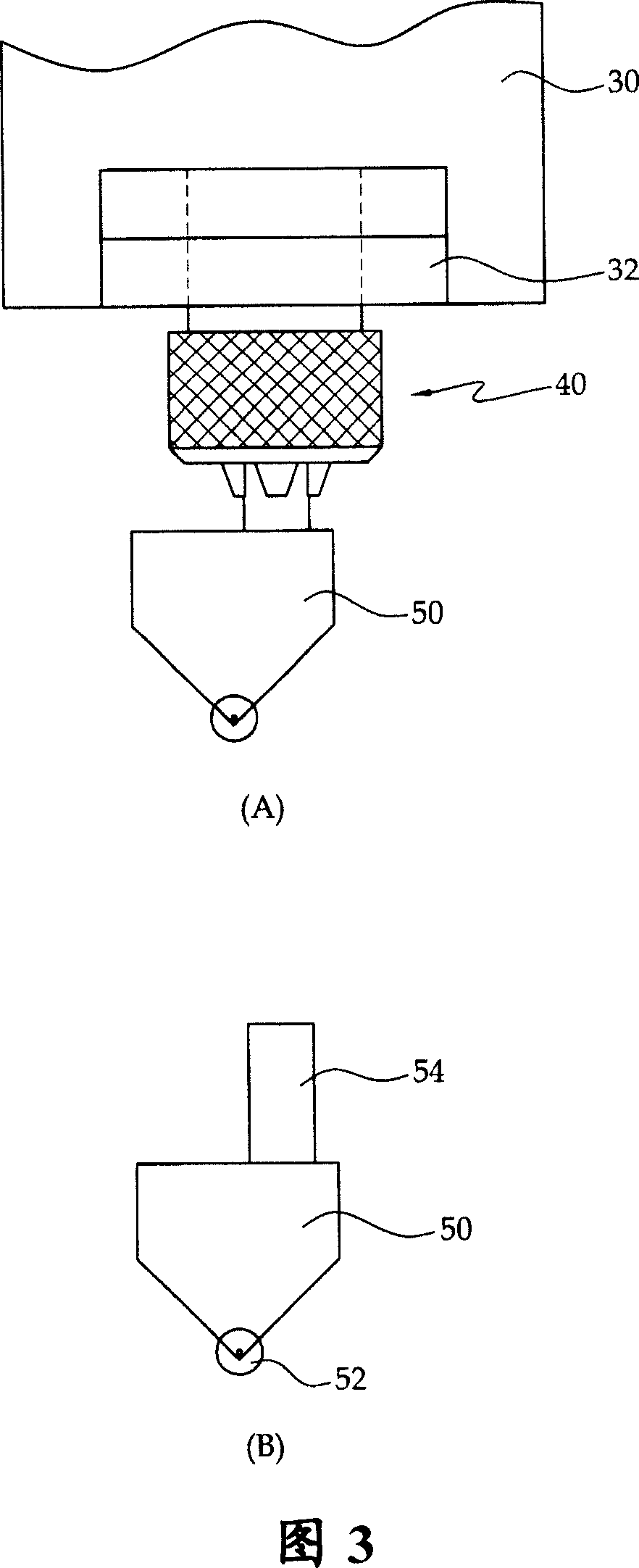

The invention provides a wheel holder assembly of scriber for cutting brittleness substrate like glass. The assembly includes a wheel holder for forming a scribed line for cutting a brittleness substrate, and a linking unit aligned on the head part of the scriber which can link with the wheel holder detachably, and a magnet aligned on the linking unit or the wheel holder for fixing the wheel holder to the linking unit by employing magnetic force. The wheel holder links with the head part of scriber, therefore it helps to detachably replacing the wheel holder.

Description

technical field [0001] The present invention relates to a wheel holder assembly for a scriber and, in particular, to a wheel holder assembly for a scriber for cutting substrates made of brittle materials such as glass. Background technique [0002] Generally, a glass substrate used as a substrate of a display is first manufactured as a large-sized substrate, which is then cut into a plurality of small-sized individual substrates suitable for its use. [0003] The process of cutting brittle materials, such as glass substrates, generally includes: scribing the surface of the substrate using a diamond-tipped tool (which has a hardness greater than that of the glass substrate) to form cut lines on the substrate; Pressurize the substrate near the cutting line to cut the substrate along the cutting line. [0004] Specifically, the scribing process is a process of rotating a cutting wheel to form cracks at cut positions of the substrate. The cutting process is a process in which ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C03B33/027

CPCY02P40/57

Inventor 金永敏孙志英

Owner TOP ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com