Vehicle body front part structure of vehicle

A technology of front structure and automobile body, applied in the direction of upper structure, upper structure sub-assembly, vehicle parts, etc., can solve the problems of pitching and swaying, failure to obtain longitudinal beam axial bending deformation, impact cannot be effectively absorbed, etc. Achieve the effect of suppressing the pitch and roll phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Hereinafter, embodiments of the present invention will be described based on the drawings.

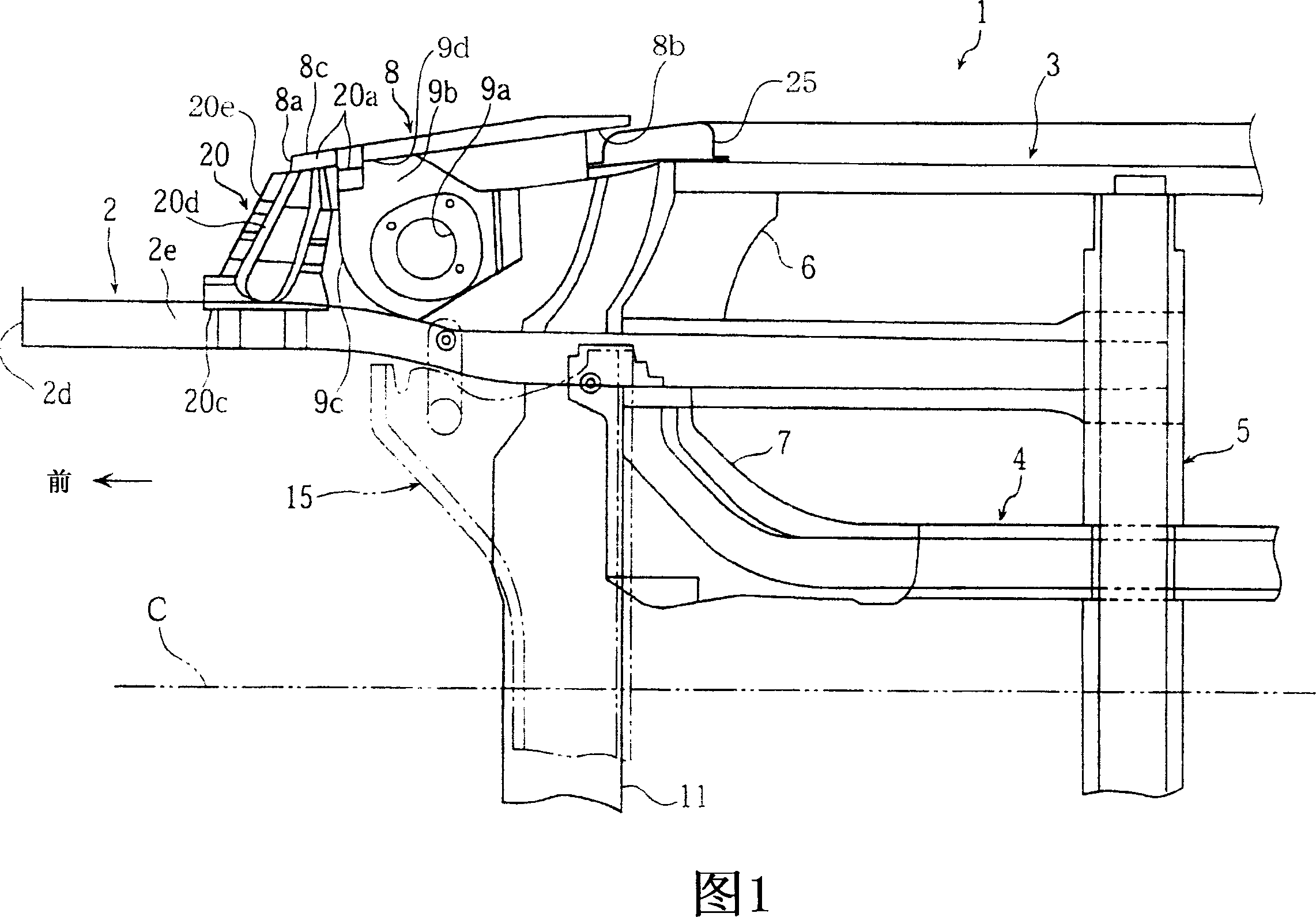

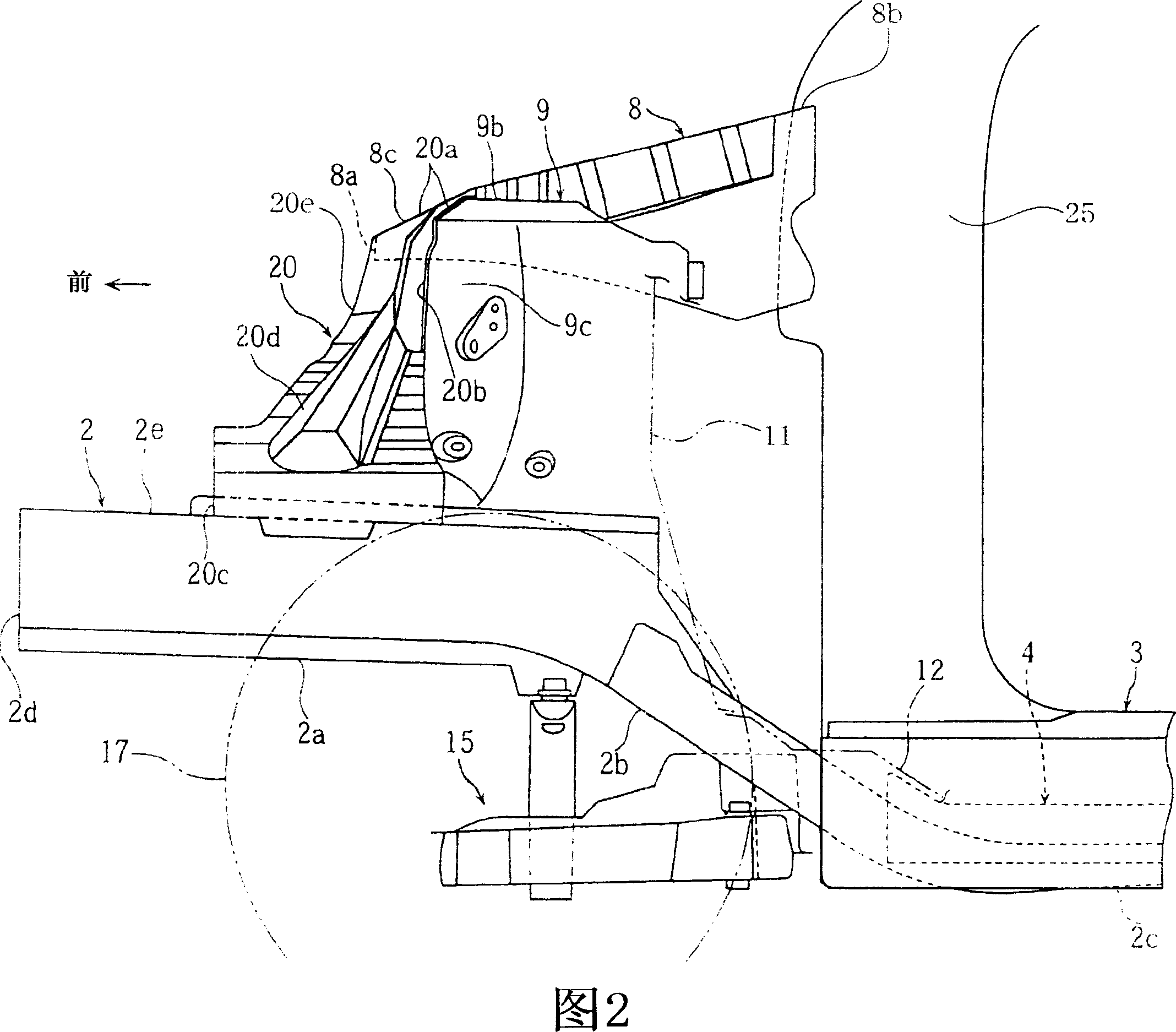

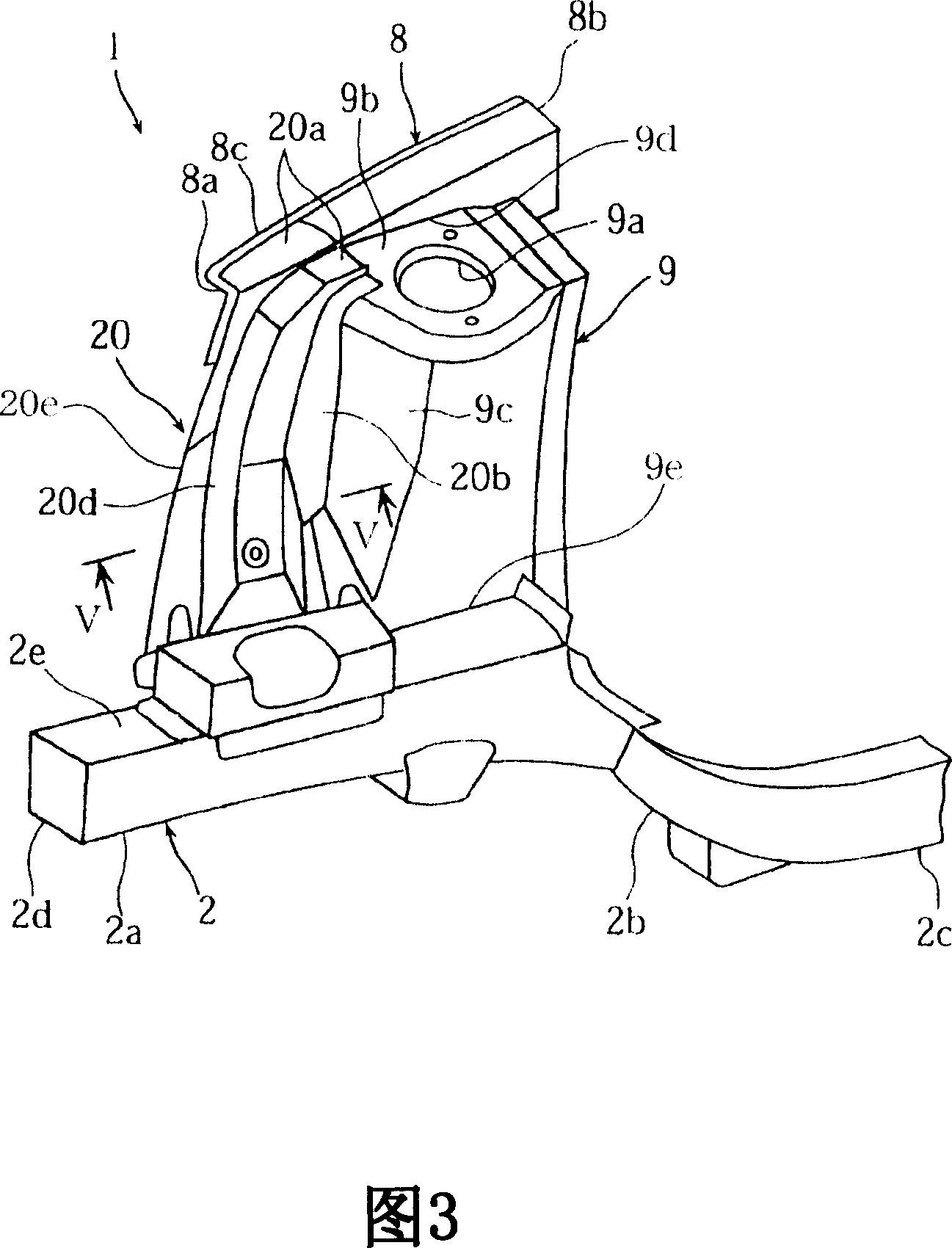

[0019] Accompanying drawing 1-5 has described the vehicle front body structure according to an embodiment of the present invention, and wherein Fig. 1 and Fig. 2 are the top view and the side view of front body frame respectively, Fig. 3 is the perspective view of front body frame, Fig. 4 and Fig. 5 is a front view and a sectional view (vertical section along the section line V-V in Fig. 3) of the rigid part, respectively.

[0020] In Fig. 1, reference numeral 1 denotes a front body frame of a vehicle, which mainly includes: left and right front side members 2, 2 extending longitudinally along the vehicle; left and right rocker rails (rocker rail) 3, 3, which Located on the lateral outsides of the left and right front longitudinal beams 2, 2, and extending substantially along a direction parallel to the front longitudinal beams 2; And basically extending along the direction par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com