Exhaust frame for a motor vehicle, fixing device comprising such frame, and method for fixing such frame

A motor vehicle and exhaust pipe technology, which is applied in the direction of exhaust device, power device, and power device gas intake, etc., can solve the problems of vibration reduction, complicated assembly of fixing device, and inability to place the fixing device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

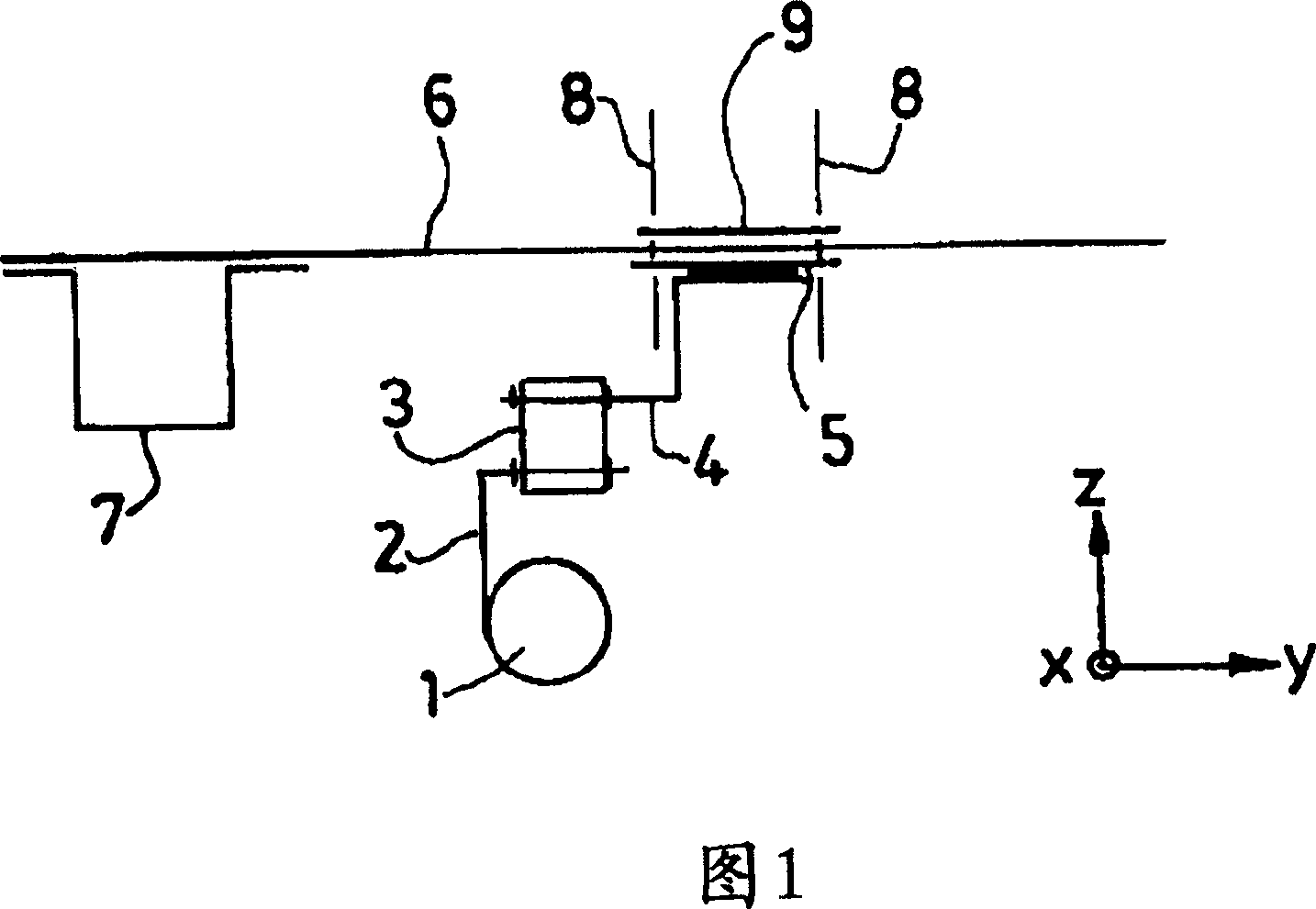

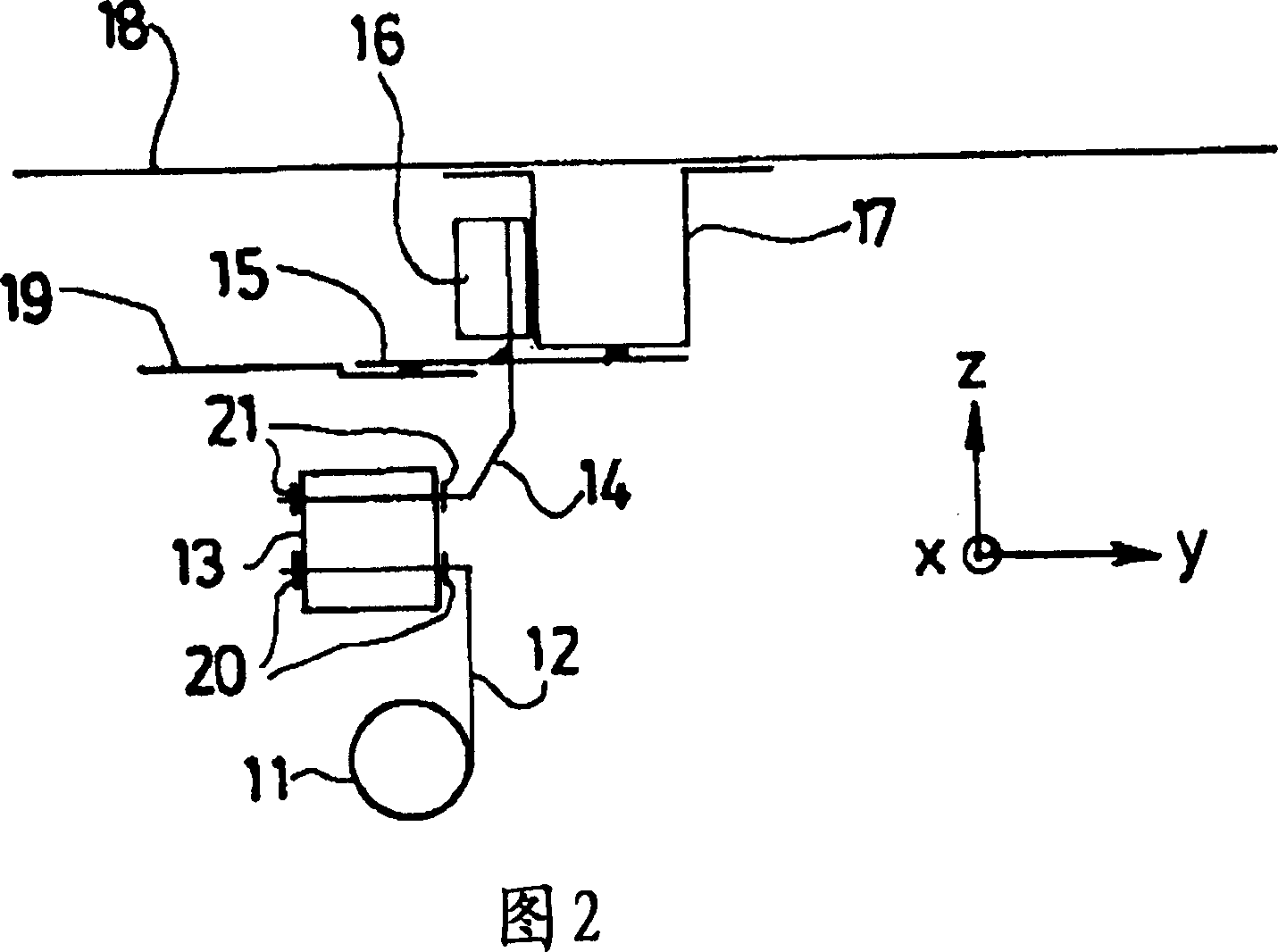

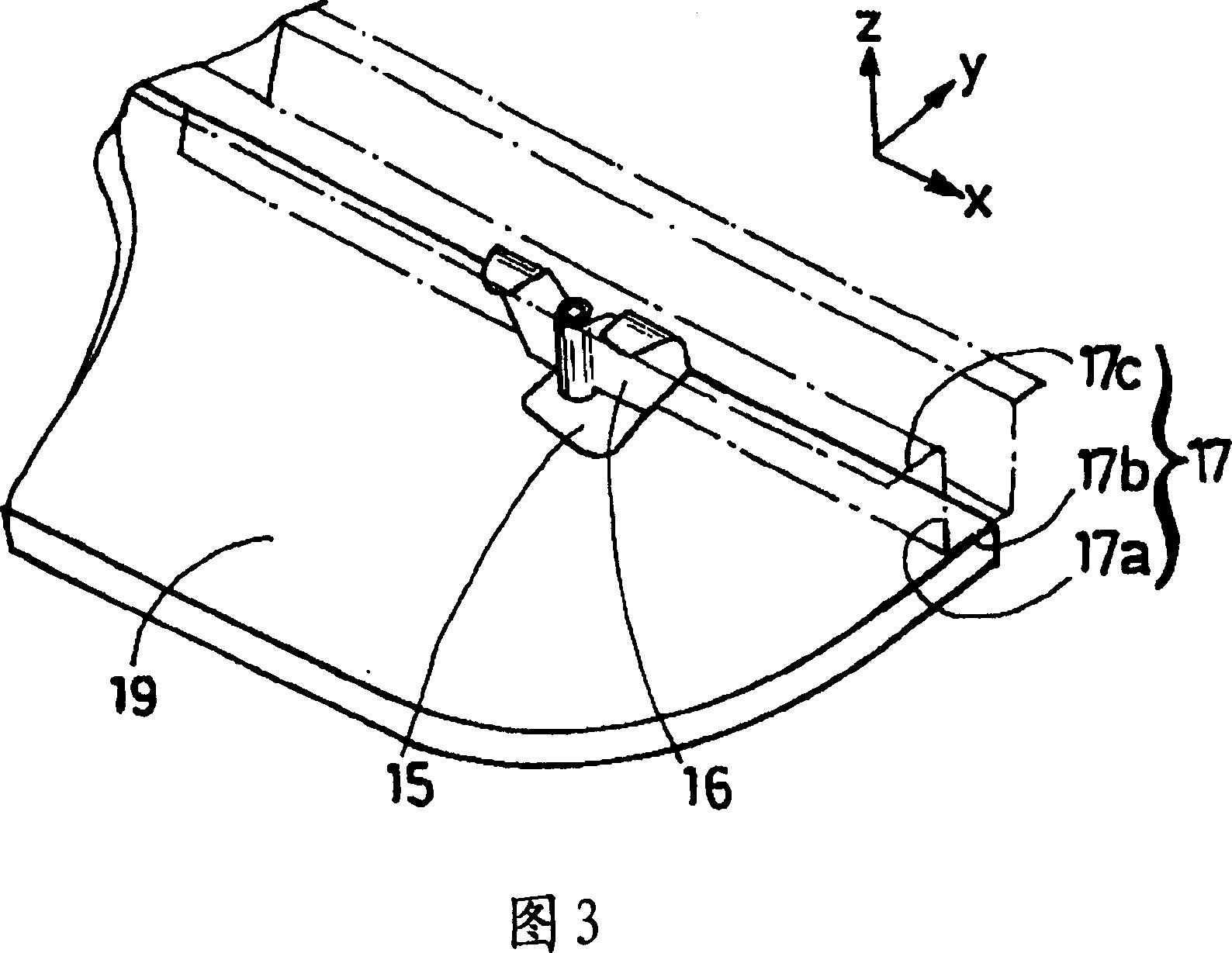

[0023] In the figures, the directions x, y and z represent the longitudinal, transverse and vertical directions of the vehicle, respectively, and the axis x points towards the rear of the vehicle.

[0024] FIG. 2 schematically shows a fixing device for a motor vehicle exhaust pipe 11 according to the invention. The device includes an exhaust pipe support rod 12 , a vibration damping filter 13 and a metal exhaust pipe support, and the metal exhaust pipe support includes a second support rod 14 , a reinforcing plate 15 and a fixing piece 16 .

[0025] Throughout the description, the term "rod" denotes a metallic elongated element of hollow or solid cylindrical cross-section. However, it is also possible to use differently shaped cross-sections for the rod. The rod is sufficiently rigid so as not to deform under the weight or vibration of the exhaust pipe.

[0026] The fastening device according to the invention is more particularly, though not limited to, an underlying motor v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com