Self-cleaning anti-fog element and manufacturing method thereof

A self-cleaning, anti-fog technology, applied in chemical instruments and methods, ion implantation plating, coating, etc., can solve problems such as not given, and achieve film damage prevention, strong photocatalytic ability, and good hydrophilicity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

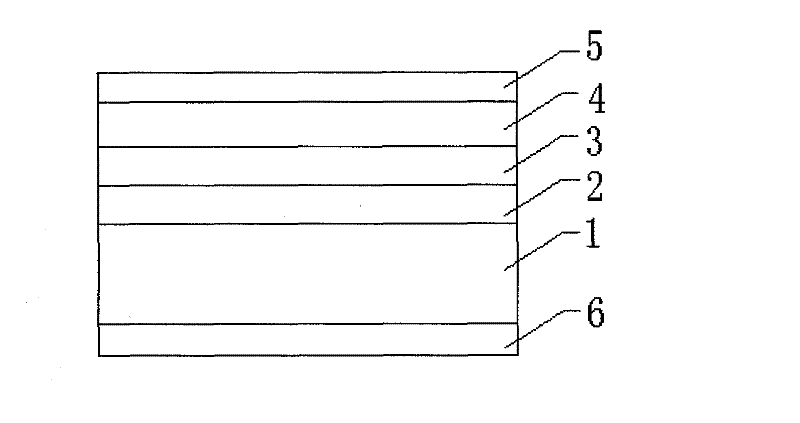

[0052] figure 1 An embodiment of a self-cleaning anti-fog element of the present invention is shown. In an embodiment, the anti-fog element comprises

[0053] Light-transmitting base material 1, this base material can be glass or plastic film, when anti-fog element of the present invention is applied to automobile rearview mirror, windshield glass or window glass, can directly rearview mirror glass, windshield glass or window glass Coating the base material to form anti-fog rearview mirrors, anti-fog glass, etc.; another embodiment of the present invention is to make the anti-fog element into a film that can be pasted and fixed on other objects. In this case, the base material Plastic films such as PET film or PMMA or PC can be selected, and the processed anti-fog film material can be cut to a specific size as required and pasted on the surface of objects t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com