Vector control method based on counter potential feedforward control

A technology of vector control and feedforward control, which is applied in vector control system, motor generator control, electromechanical brake control, etc. It can solve the problems of low control precision, oversaturation of current or voltage, easy pulsation of torque, etc. The effect of wide range and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with drawings and embodiments.

[0023] This embodiment includes the following steps:

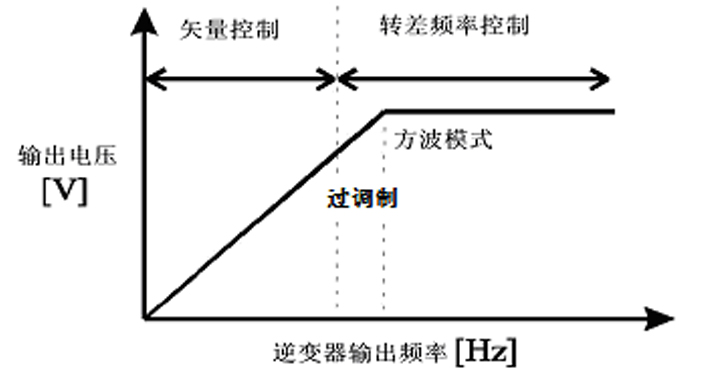

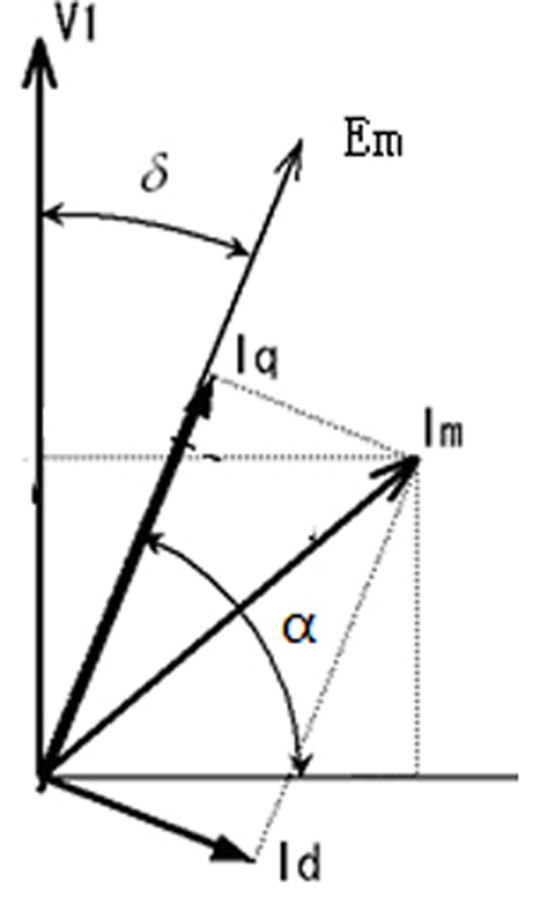

[0024] (1) Obtain the V / F ratio of the motor through the characteristic curve of the asynchronous traction motor, and obtain the required amplitude of the back EMF of the asynchronous traction motor according to the product of the inverter output frequency and the V / F ratio;

[0025] (2) given excitation current and torque current;

[0026] (3) The phase angle of the back EMF of the asynchronous traction motor is obtained by the integral of the inverter output frequency;

[0027] (4) The three-phase stator current of the asynchronous traction motor is obtained by sampling the current sensor, and the amplitude and phase angle of the stator current vector of the asynchronous traction motor are calculated;

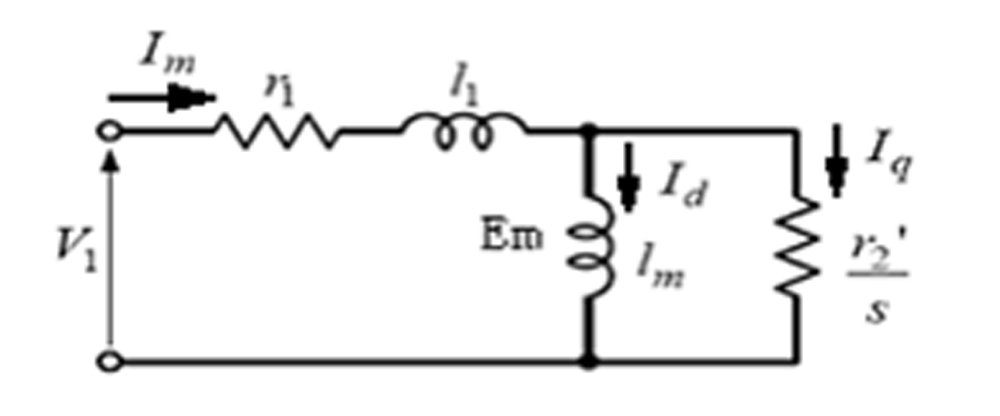

[0028] (5) Obtain the compensation voltage vector amplitude and phase angle of the current on the stator imped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com