Double-sided pressure sensitive adhesive tape capable of movement in short time, and preparation method thereof

A pressure-sensitive adhesive, short-time technology, applied in the direction of film/sheet adhesive, adhesive type, ester copolymer adhesive, etc., can solve adhesive tape movement, material waste, and reduce production efficiency And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

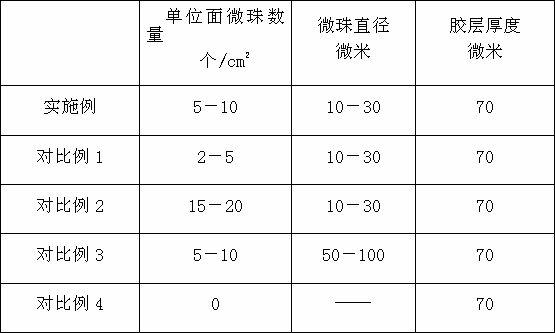

Image

Examples

Embodiment 1

[0017] The pressure-sensitive adhesive described in the present invention is an acrylate pressure-sensitive adhesive, and the acrylate pressure-sensitive adhesive is usually based on (meth)acrylic acid alkyl ester and has a free radical polymerizable unsaturated group and at least one Obtained by copolymerization of monomers with reactive functional groups.

[0018] Commonly used alkyl (meth)acrylates include: methyl (meth)acrylate, ethyl (meth)acrylate, n-butyl (meth)acrylate, isobutyl (meth)acrylate, 2-Ethylhexyl (meth)acrylate, n-octyl (meth)acrylate, isooctyl (meth)acrylate, lauryl (meth)acrylate, octadecyl (meth)acrylate, etc. . The above monomers may be used alone or in combination of two or more. The amount of the monomer accounts for 80-99% of the total amount of monomers.

[0019] The commonly used ones that can be listed as functional monomers are: (meth)acrylic acid, itaconic acid, (meth)hydroxyethyl acrylate, (meth) hydroxyethyl acrylate, (meth)hydroxypropyl acr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com