Design method for improving waterflooding effect of anisotropic oil reservoir

An anisotropy and design method technology, applied in the field of oilfield development and research, can solve problems such as unbalanced displacement of injected water, small sweeping range, and large difference in water breakthrough time of production wells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] An Indoor Experimental Example of Different Direction Well Spacing Design Method

[0088] 1. Instructions for making simulation models

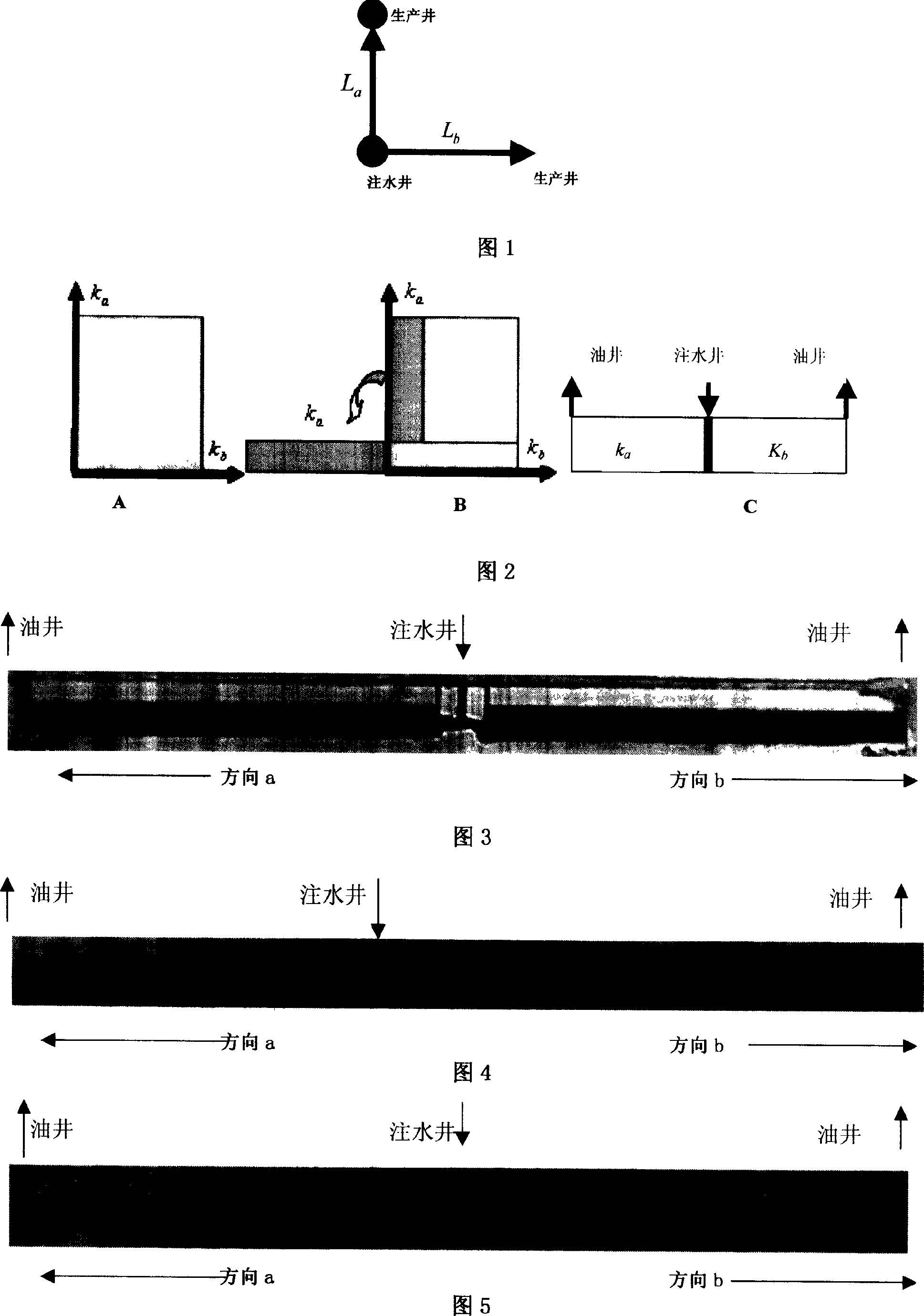

[0089] Fig. 2(A) is a schematic diagram of an anisotropic reservoir, the direction with lower permeability is set as the reference direction, denoted by direction a, and its permeability is k a ; The direction with higher permeability is indicated by direction b, and its permeability is k b . In order to facilitate the production of physical simulation models, the anisotropic model is abstracted and simplified into two different permeability strips, and the permeability strips in the direction a are rotated 90 degrees counterclockwise (Fig. 2(B)). The anisotropic model shown in Fig. 2(C) is obtained.

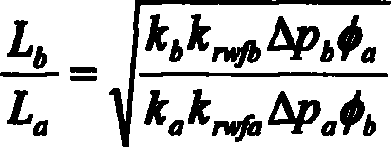

[0090] The test model is made by filling a glass plate with pure quartz sand. Since the glass is transparent and the quartz sand is lighter in color, the entire model is transparent in transmitted light. The experimental simulated o...

Embodiment 2

[0108] An Indoor Experimental Example of Design Method of Injection-production Pressure Difference in Different Directions

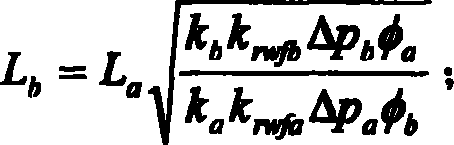

[0109] The production simulation experiment model of the different injection-production pressure difference design method adopts the equal well spacing model used in the comparison in Example 1, that is, k a =1543.8×10 -3 μm 2 , k b =3279.3×10 -3 μm 2 ; a = φ b =0.36;k rwfa =k rwfb .

[0110] In the model, the simulated well spacing is 0.2m, that is, L a = L b =0.2m (equivalent to 200m well spacing under reservoir conditions);

[0111] Set the injection-production pressure difference in the reference direction, that is, direction a, as 0.015MPa, that is, Δp a =0.015MPa (equivalent to 15MPa under reservoir conditions).

[0112] According to the ratio of injection-production pressure difference design in different directions, the injection-production pressure difference in direction b can be obtained as

[0113] Δp ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com