Wind-energy compressor using wind energy to compress air

A technology for compressing gas and heaters, applied in the field of wind energy heaters, which can solve the problems of insufficient utilization of wind energy, environmental pollution, and high cost, and achieve the effects of high wind energy utilization efficiency, cost reduction, and no environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

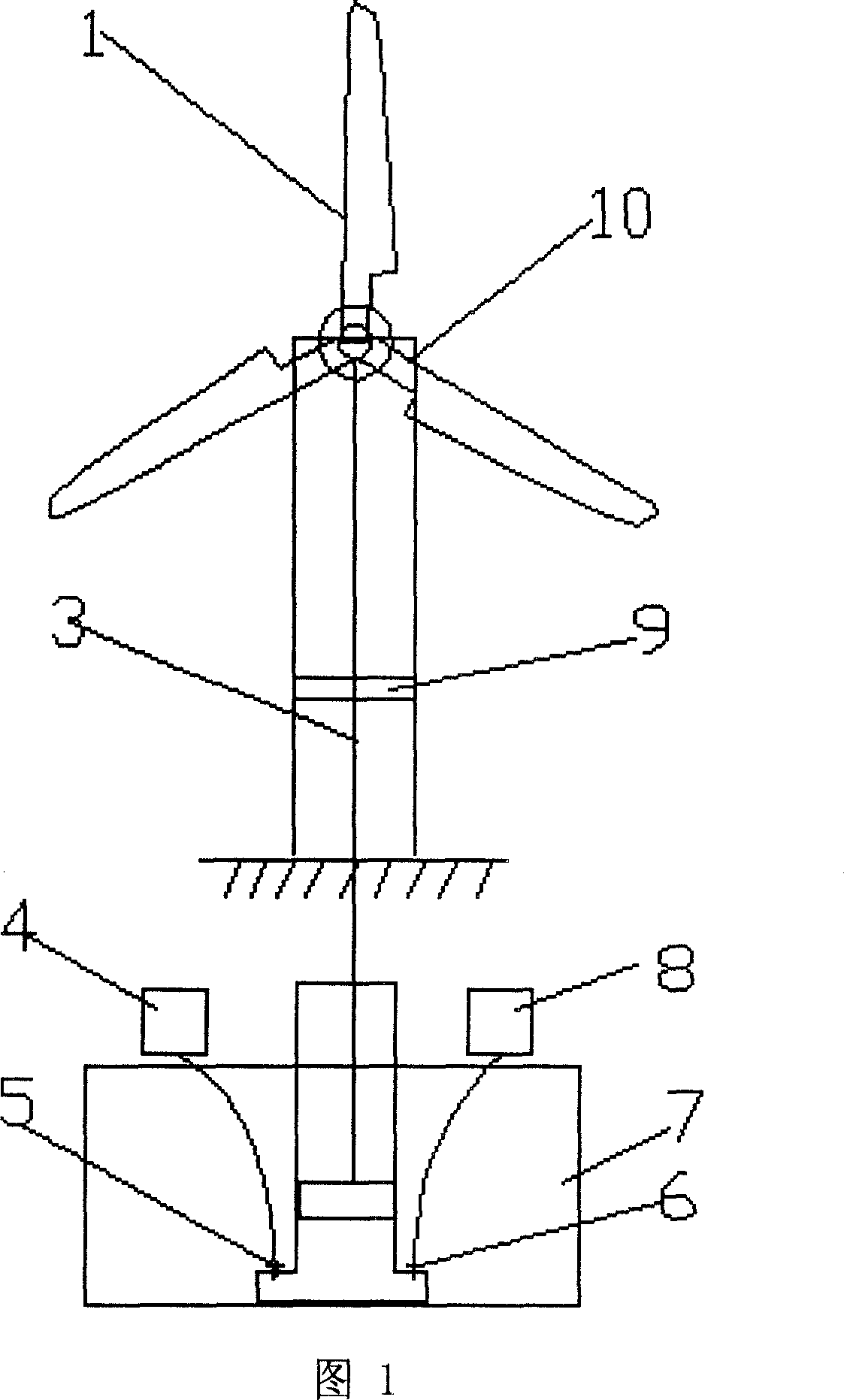

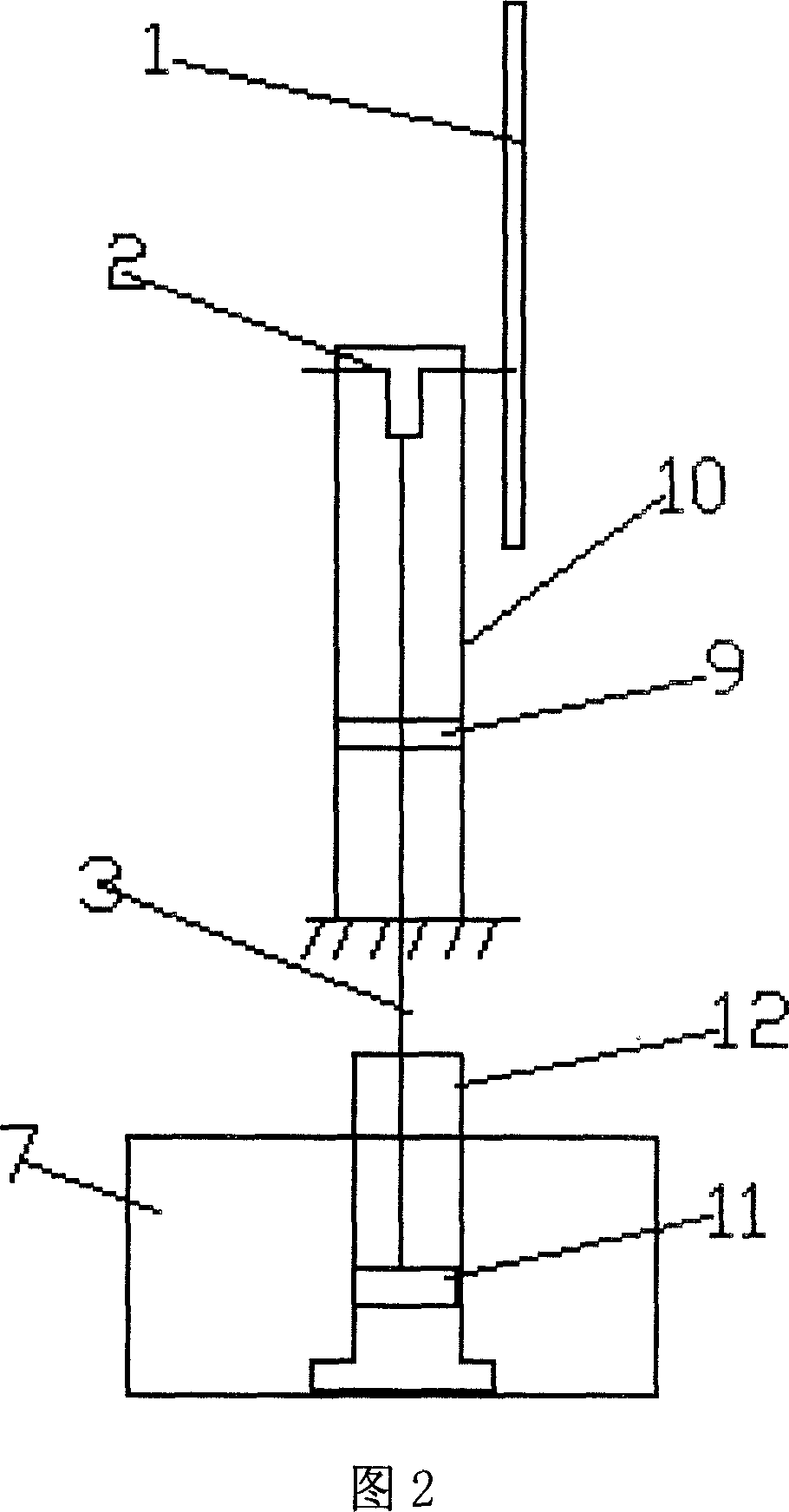

[0013] See Figure 1 and Figure 2. In the figure: 1. wind wheel, 2. crankshaft, 3. connecting rod, 4. pressure tank, 5. exhaust valve, 6:. intake valve, 7. water tank, 8. pressure tank, 9. turntable, 10. Tower frame, 11. piston, 12. cylinder.

[0014] The wind wheel 1 and the crankshaft 2 are connected together, and the crankshaft 2 is fixed on the upper end of the tower 10 . The piston 11 is connected with the crankshaft 2 through the connecting rod 3, reciprocates in the cylinder 12 as the crankshaft 2 rotates, compresses the gas in the cylinder 12 to do work, and converts mechanical energy into heat energy. Heat energy is conducted to the water tank for collecting heat energy through the cylinder, and the water tank is connected with the indoor heating device or the hot water storage. The exhaust valve 5 is installed on the cylinder 12. When the temperature of the gas in the cylinder 12 is too high and the pressure is too high, the valve opens to discharge a certain amount...

Embodiment 2

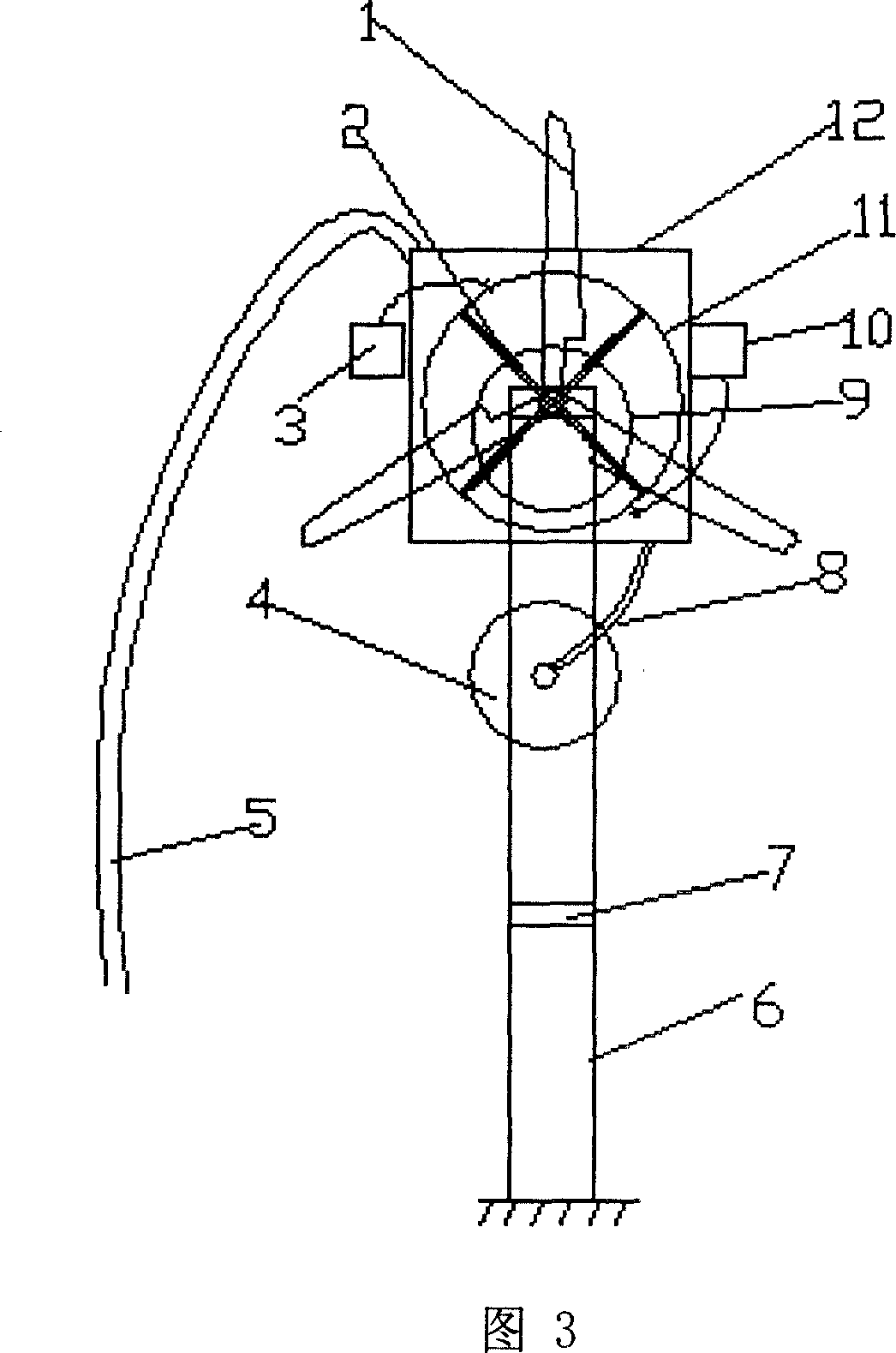

[0016] See Figure 3 and Figure 4. In the figure: 1. Wind wheel, 2. Slider, 3. Pressure tank, 4. Air collector, 5. Air duct, 6. Tower, 7. Turntable, 8. Air duct, 9. Rotor, 10. Pressure tank , 11. Stator, 12. Collector, 13. Main shaft.

[0017] The wind wheel 1 and the rotor 9 are connected together through a main shaft 13, and both ends of the main shaft 13 are fixed on the heat collector 12 with bearings. The rotor 9 is installed eccentrically on the stator 11. When the rotor 9 rotates, the slides 2 are pressed against the inner wall of the stator 11 under the action of centrifugal force, and the space between two adjacent slides 2 changes continuously during the rotation. Compressed gas does work, converting mechanical energy into heat. The stator 11 conducts heat energy to the air in the heat collector 12, and the heat collector 12 is fixed on the tower, and the lower part is effectively connected with a funnel-shaped wind collector 4 through the air pipe 8, and the wind e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com