Plug-in type electromagnetic vortex flowmeter

A flowmeter, plug-in technology, applied in the direction of volume measurement, liquid/fluid solids measurement, volume/mass flow generated by mechanical effects, etc. The problem of high production cost is to achieve the effect of simple and novel structure, easy processing, manufacturing, installation and maintenance, and reliable work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

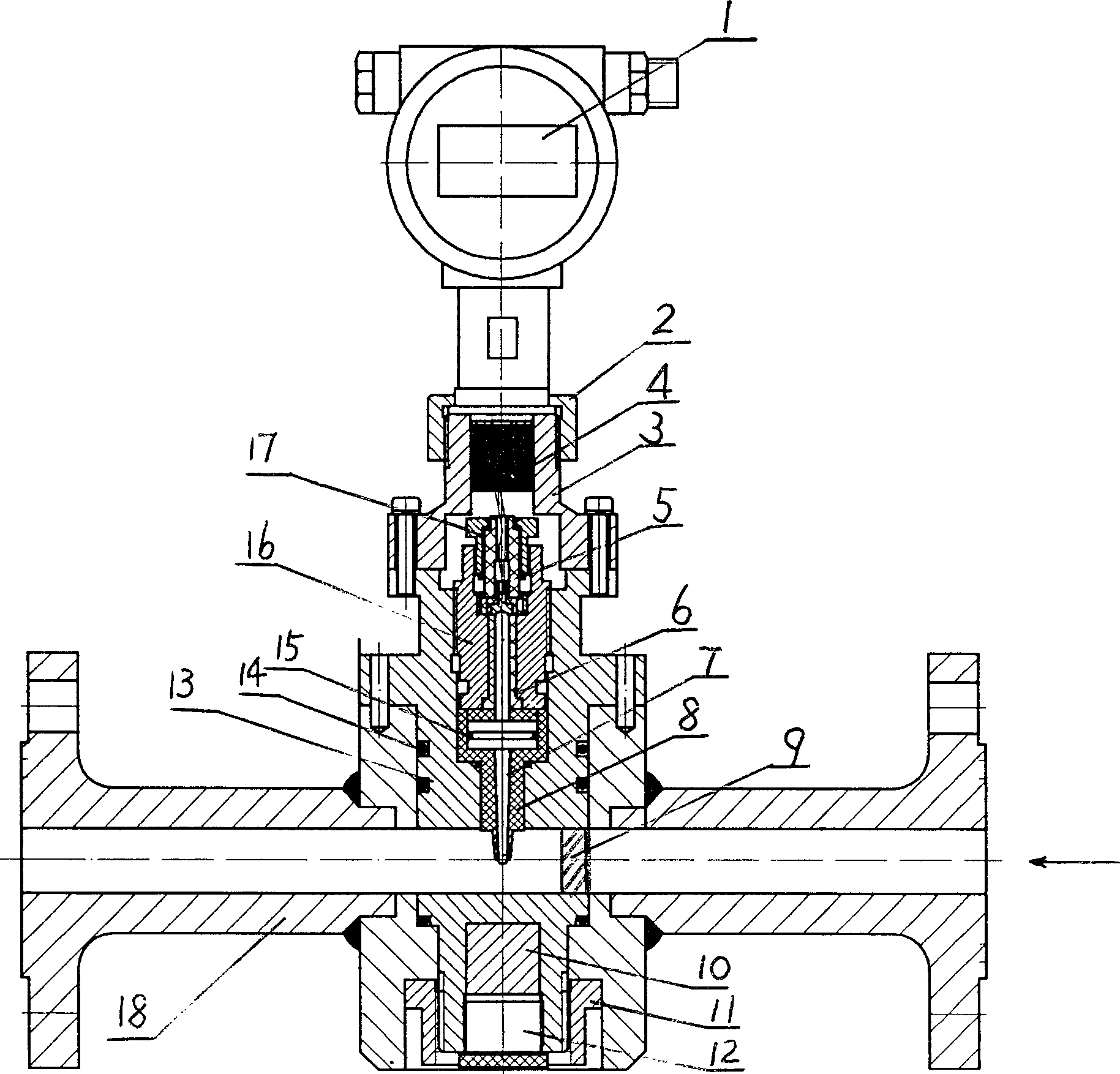

[0007] The present invention will be further described below in conjunction with accompanying drawing.

[0008] As shown in the figure, the present invention consists of an integrator 1, an upper pressure cap 2, an upper gland 3, a sensor 4, a polytetrafluoro jacket 5, 6, a probe 7, a polytetrafluoro jacket 8, a swirl generator 9, Magnetic steel 10, lower spare cap 11, lower gland 12, main body 13, sealing rings 14, 15, support frame 16, locking nut 17 and connecting body 18, its structure and assembly relationship are as follows: Above the cap 2 on the core body; a support frame 16 is provided in the cavity of the core body body 13, and a probe 7 is provided in the middle hole of the support frame 16, and two upper and lower PTFE sheaths are set on the upper and middle outer sides of the probe 7 5, 6, the lock nut 17 on the upper sheath is screwed to the support frame 16 with threads, and the outer part of the lower part is set with a polytetrafluoroethylene jacket 8, and a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com