High beam light-emitting intensity detecting method of vehicular head light detector and detecting mechanism thereof

A luminous intensity detection and headlight technology, which is applied in the direction of testing the alignment of automobile headlights, photometry, and testing optical performance, etc., can solve problems such as errors, and achieve the effect of good adaptability and high measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

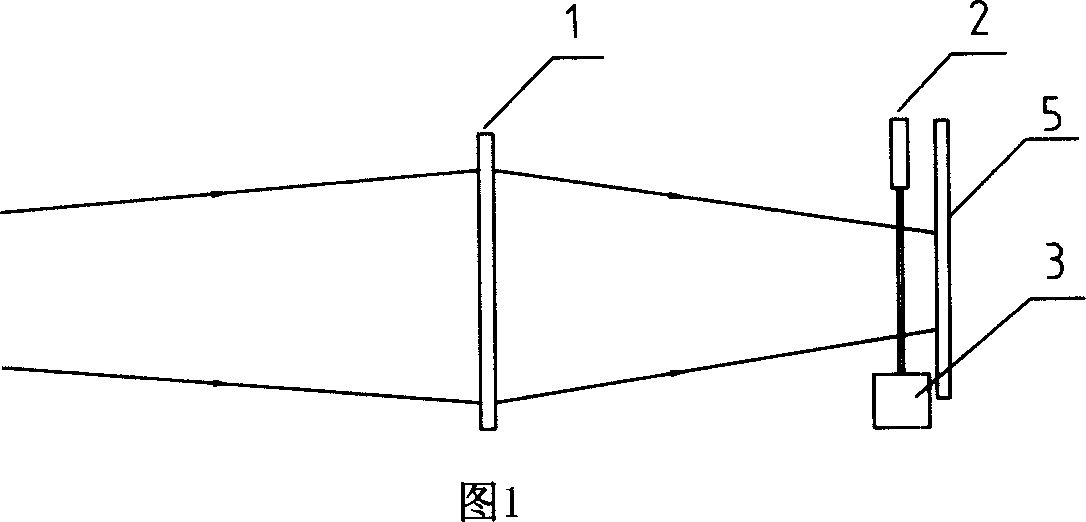

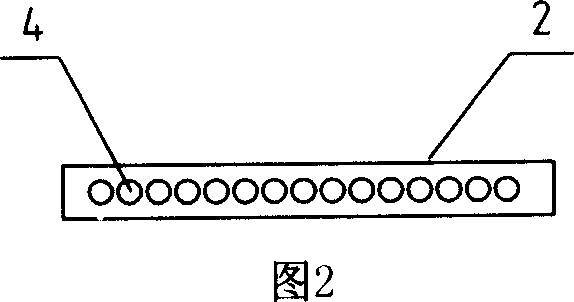

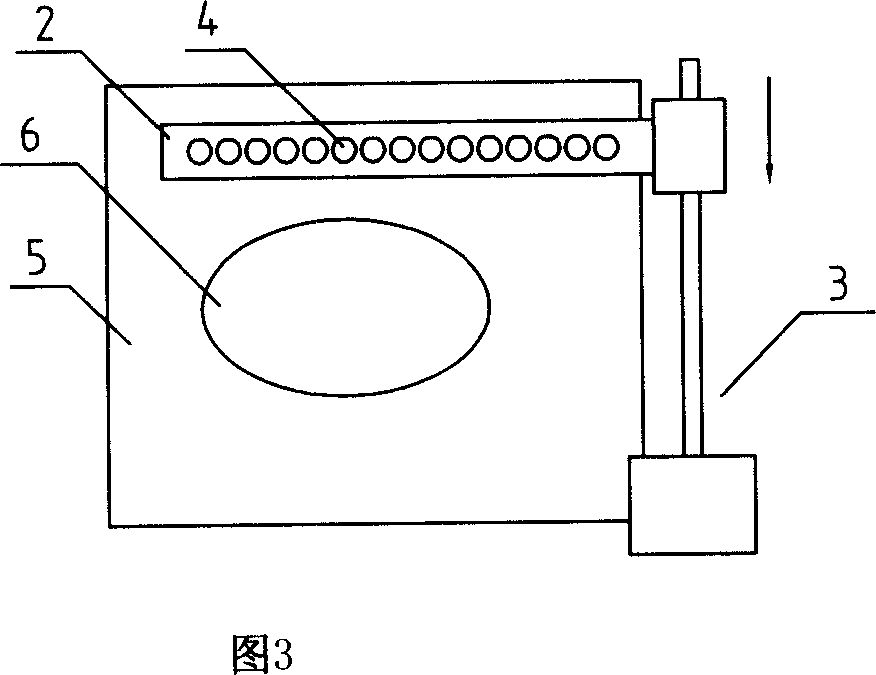

[0015] With reference to Fig. 1, Fig. 2, there are several photoelectric conversion elements 4 arranged in a straight line on the light intensity detection plate 2 behind the lens in the vehicle headlamp tester in this embodiment. The photoelectric conversion element 4 is a photovoltaic cell. The light intensity detection board 2 is installed on the dragging mechanism 3 that can move on the vertical plane where the light beam projects. When the beam of the high beam of the vehicle headlight passes through the lens 1 and converges, its beam is projected on the screen 5 to form a beam projection 6, and the drag mechanism 3 drives the light intensity detection plate 2 on the vertical plane of the beam projection under the control of the controller. move up. Under the control of the controller, the drag mechanism 3 drives the light intensity detection board 2 to move up and down on the vertical plane where the light beam is projected, as shown in FIG. 3 . Or the drag mechanism 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com