Enhanced elastomer coated, protective barrier fabric and process for producing same

A technology for barrier fabrics, fabrics, applied in the direction of chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problem of shortening the service life of barrier fabrics, delamination, pinhole protection performance damage, adhesives and/or or polymer adhesion failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

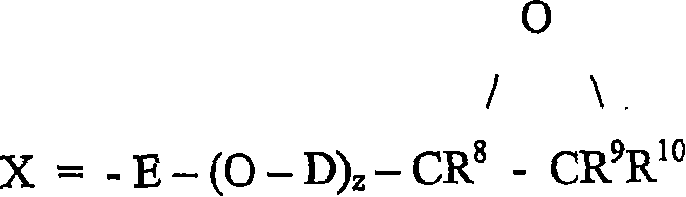

[0057] The present invention relates to selected cold-cure compositions and a two-step process for applying a coating of the composition to one side of a woven fabric, preferably a polyester-containing fabric.

[0058] In this way, excellent reusable barrier fabrics or barrier fabric articles can be produced; in particular, barrier fabrics or barrier fabric articles that meet the stringent technical standards required for medical virus / fluid barrier applications .

[0059] Preferably, the manner in which the soft fabric is laminated to the coated "inside" side of the woven fabric is typically: i) sewing the coated barrier fabric to a prefabricated textile process article such as a surgical gown or surgical drapes); or (ii) sewing the coated barrier fabric to the textile material before the textile material and the coated barrier fabric are made into a finished article such as the surgical gown or surgical drapes described above .

[0060] The solvent-free and filler-free col...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com