Method for synchronous fermentation of bacillus liquid for use in microbial manure

A technology of microbial fertilizer and bacillus, which is applied in the field of simultaneous fermentation of bacillus liquid, can solve the problems of uneven growth of bacteria, different growth starting points, and difficulty in production control, so as to reduce the probability of pollution and improve product quality. , Conducive to the effect of production control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

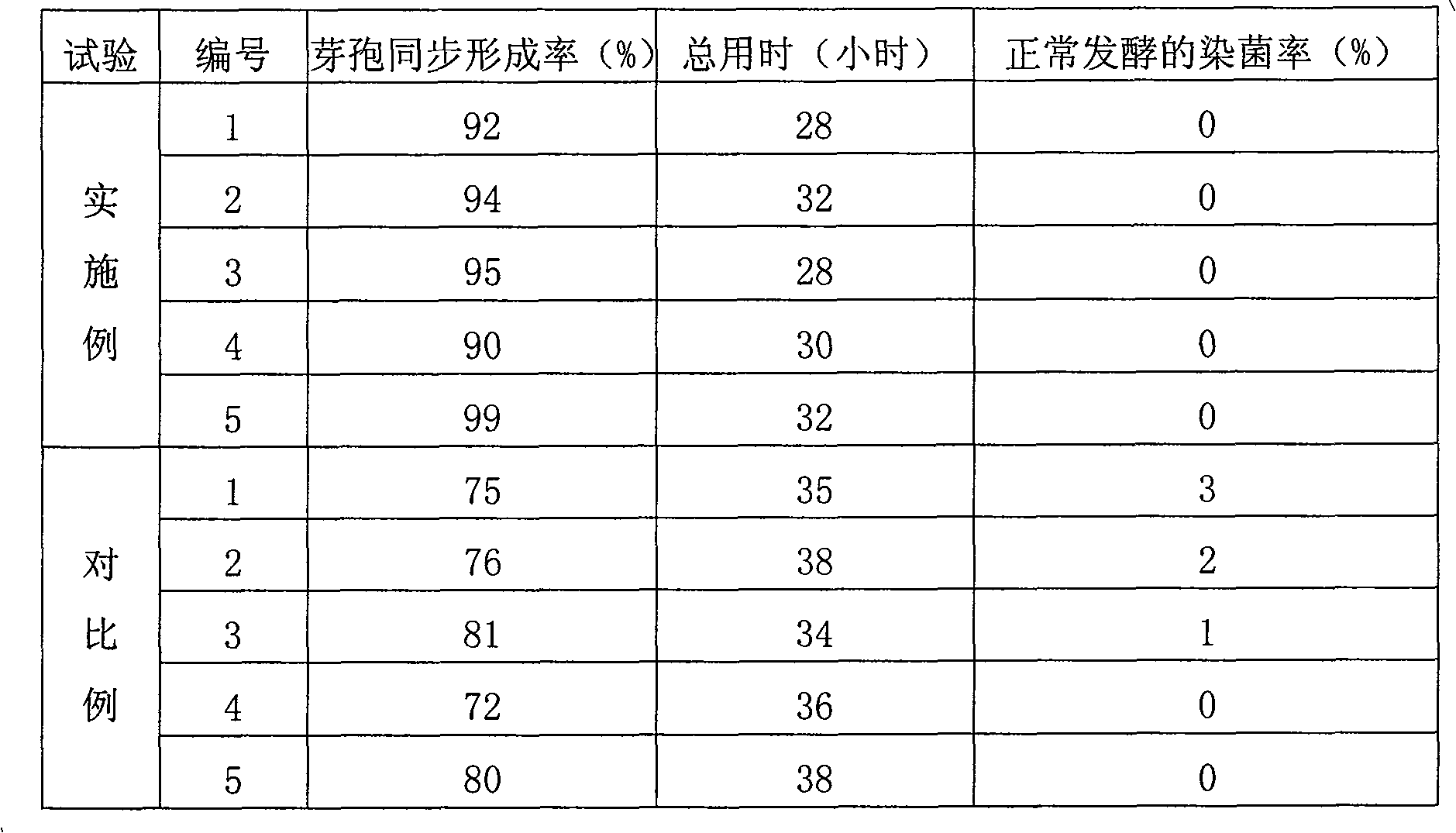

Examples

Embodiment 1

[0023] With the nutrient solution of bacillus megaterium (by weight percentage, starch 3%, bean cake powder 1%, corn steep liquor 0.1%, K 2 HPO 4 0.5%, (NH 4 ) 2 SO 4 0.2%, CaCO 3 0.5%, pH7.2-7.5) 300 kilograms add the fermenter of the external heat exchange jacket that has agitator, be warmed up to 121 ℃, pressure reaches 0.11MPa, heat preservation and pressure-holding 30 minutes carry out sterilization. Then slowly lower the temperature to 90°C, and at the same time reduce the pressure in the tank to normal pressure. In the normal working state of the fermentation workshop, light the fire ring around the inoculation port of the tank, and open the inoculation cover of the fermentation tank under the protection of the flame. , quickly add pure bacillus megaterium liquid seeds into the fermenter, and then close the inoculation cover to make the tank body airtight. Turn on the agitation, keep the tank temperature at 90° C. and normal pressure for 15 minutes, and carry out t...

Embodiment 2

[0027] With the nutrient solution of bacillus licheniformis (by weight percentage, starch 0.5%, K 2 HPO 4 0.2%, (NH 4 ) 2 SO 4 0.1%, MgSO 4 0.05%, Yeast Extract 0.1%, CaCO 3 0.1%, pH7.0-7.3) 300 kilograms add the fermenter of the external heat exchange jacket that has agitator, be warmed up to 121 ℃, pressure reaches 0.11MPa, heat preservation and pressure-holding 35 minutes carry out sterilization. Then slowly lower the temperature to 90°C, and at the same time reduce the pressure in the tank to normal pressure. In the normal working state of the fermentation workshop, light the fire ring around the inoculation port of the tank, and open the inoculation cover of the fermentation tank under the protection of the flame. , quickly add pure Bacillus licheniformis liquid seeds into the fermenter, and then close the inoculation cover, so that the tank body is in an airtight state. Turn on the agitation, keep the tank temperature at 85° C. and normal pressure for 20 minutes,...

Embodiment 3

[0031] The culture medium of Bacillus lateralis (by weight percentage, peptone 0.5%, bean cake powder 0.2%, yeast powder 0.2%, starch 1%, sucrose 0.5%, K 2 HPO 4 0.2%, MgSO 4 0.05%, CaCO 30.01%, pH7.0-7.5) 300 kilograms add the fermenter of the external heat exchange jacket that has agitator, be warmed up to 121 ℃, pressure reaches 0.11MPa, heat preservation and pressure-holding 35 minutes carry out sterilization. Then slowly lower the temperature to 88°C, and at the same time reduce the pressure in the tank to normal pressure. In the normal working state of the fermentation workshop, light the fire ring around the inoculation port of the tank, and open the inoculation cover of the fermentation tank under the protection of the flame. , quickly add the pure Bacillus lateralis sporogenes liquid seeds into the fermenter, and then close the inoculation cover, so that the tank body is airtight. Turn on the agitation, keep the tank temperature at 88° C. and normal pressure for 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com