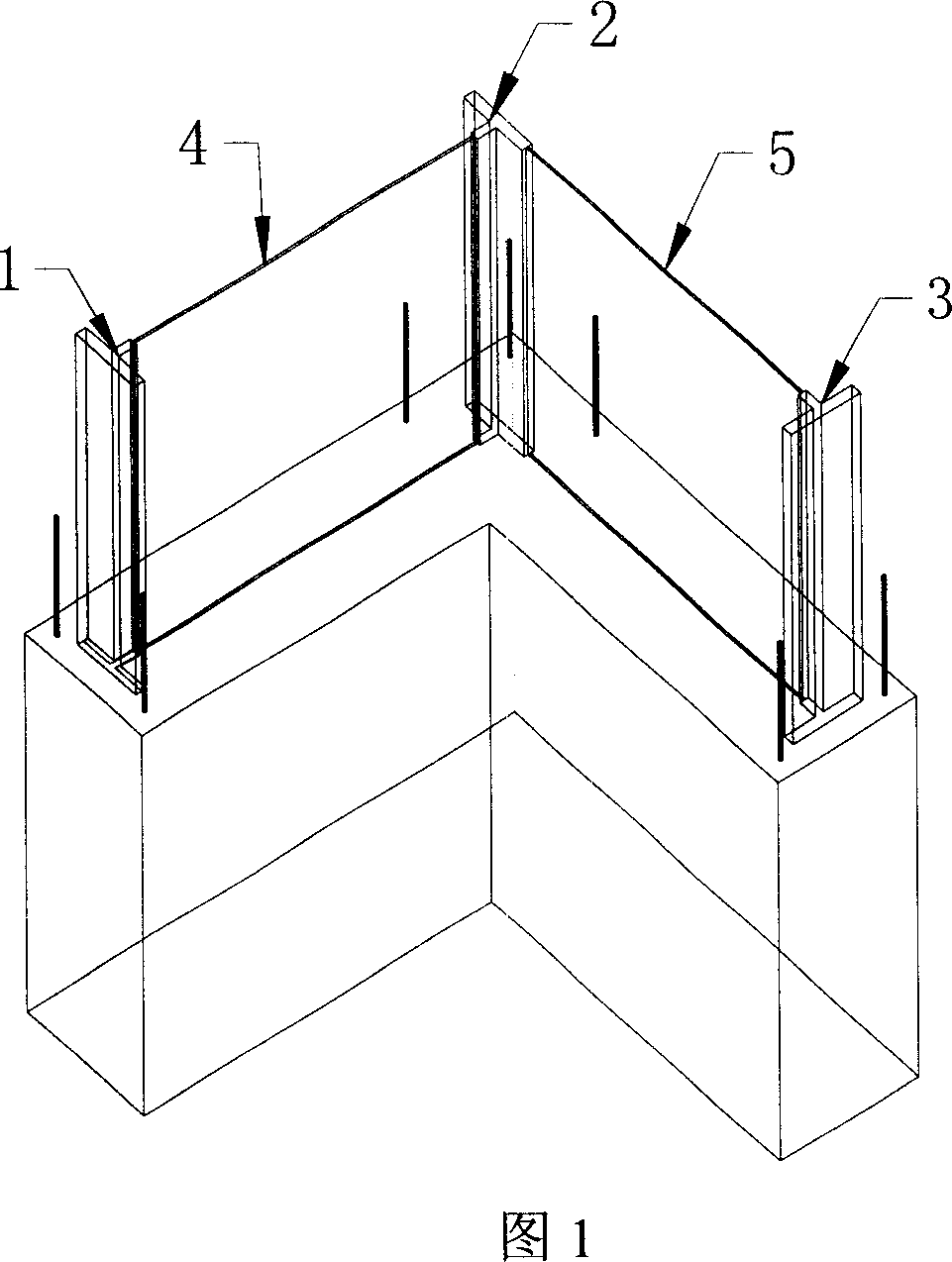

L-shape steel concrete profiled pole with solid-web steel framework

A technology of concrete and special-shaped columns, applied in the direction of columns, piers, pillars, etc., can solve problems such as unreachable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

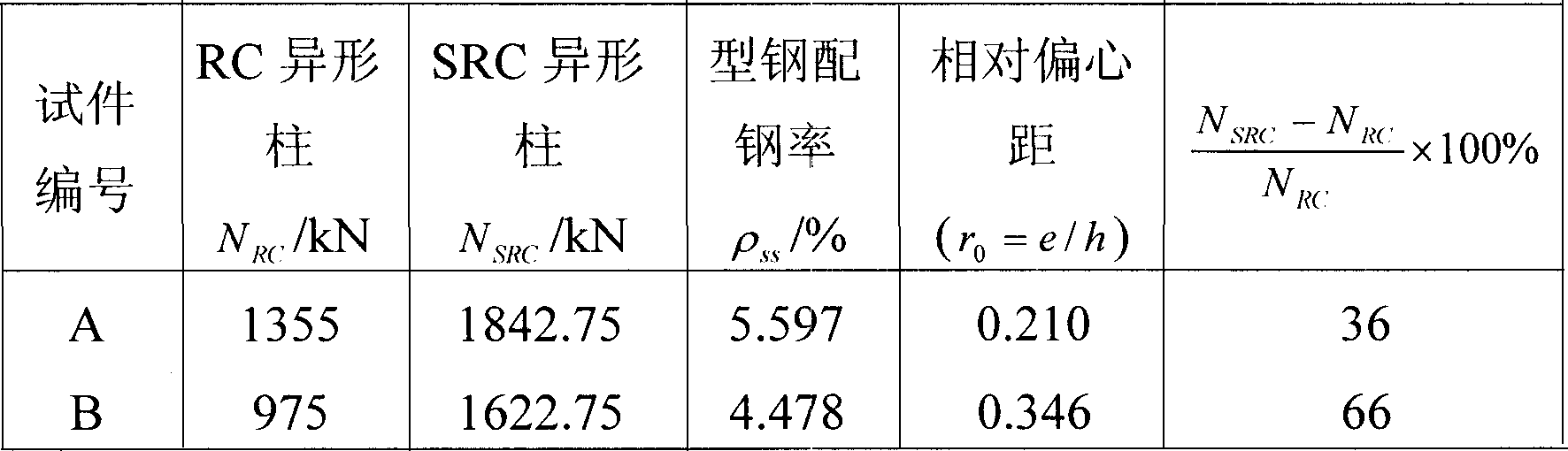

[0013] In order to achieve the purpose of effectively improving the bearing capacity and seismic performance of special-shaped columns, the steel ratio of the section should not be too low or too high. The gripping force of concrete to steel is reduced, which affects the bonding force of both. Combined with my country's national conditions, the cross-sectional steel ratio is 4% to 10%. Through experimental research, the ultimate bearing capacity of SRC special-shaped columns with steel ratios in this range is 36% higher than that of RC special-shaped columns with the same cross-section. % above (see Table 1). The bond strength between steel and concrete is about 2.5MPa, and the slippage between steel and concrete is less than 0.4mm.

[0014] Table 1 Comparison of ultimate bearing capacity of SRC special-shaped columns and RC special-shaped columns

[0015] For the L-shaped steel concrete special-shaped column with solid abdominal steel skeleton, in order to ensure the coope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com