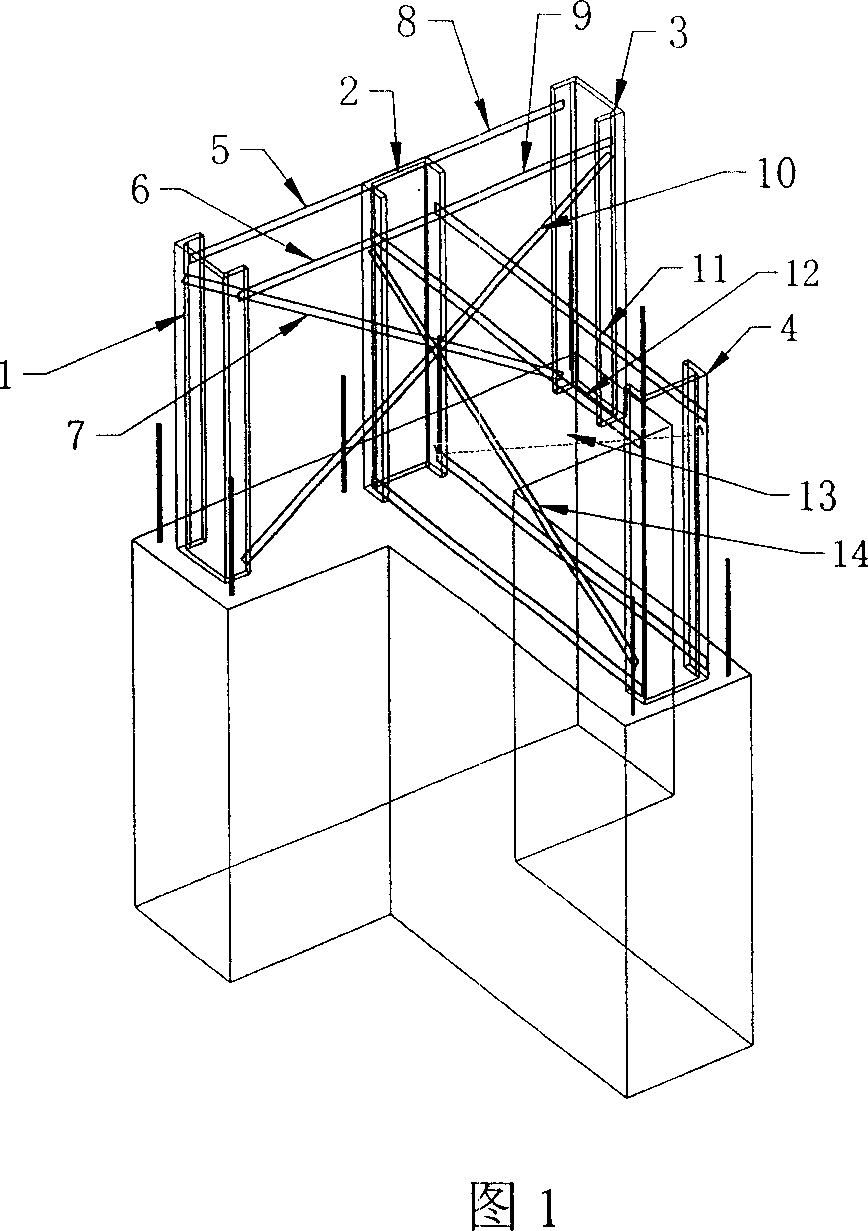

T-shape steel concrete profiled pole with pen-web channel beam framework

A technology of concrete and special-shaped columns, applied in the directions of columns, piers, pillars, etc., can solve problems such as unreachable, and achieve the effect of improving seismic performance and bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

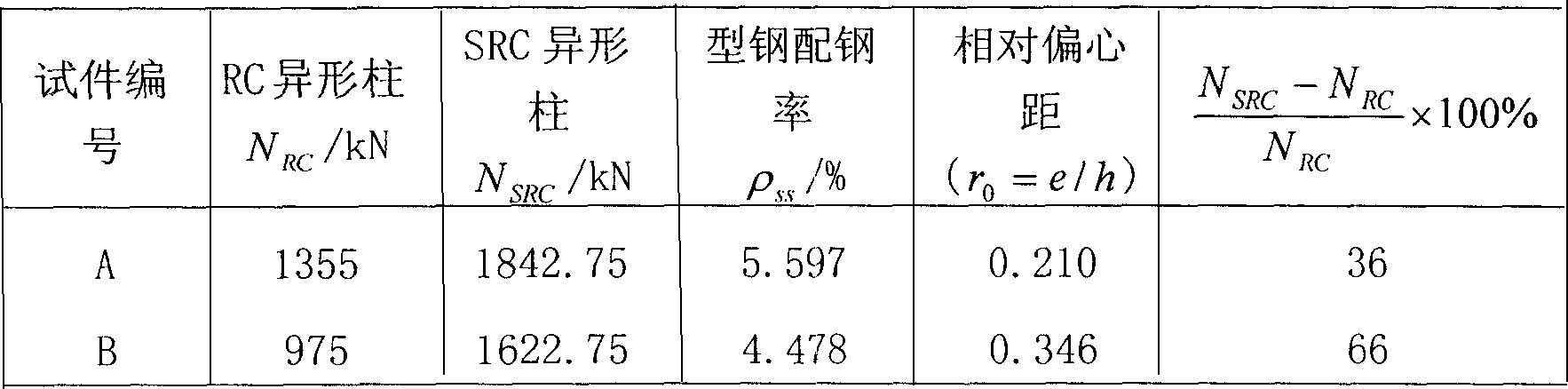

[0013] The T-shaped steel concrete special-shaped column with channel steel hollow frame, the web in the frame can bear the transverse shear force between the steel and concrete and at the same time play the role of a stud, which is very beneficial to ensure the cooperative work of the steel and concrete. Moreover, the webs can transmit shear force between the columns, which can effectively prevent the shear lag phenomenon of the special-shaped column section. Due to the repetitive nature of the earthquake, the configuration of cross webs can effectively improve the seismic performance and shear capacity. The cross webs are welded on both sides of the channel steel, and form a whole space with the channel steel, which not only has good overall rigidity to bear the load during the construction stage, but at the same time, the closed space formed by the web bars and the channel steel exerts certain constraints on the internal concrete It is very beneficial to improve the bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com