Ice making machine for use in refrigerator

An ice machine and mechanical connection technology, which is applied in the field of drive control modules for ice machines, can solve the problems that the ice machine is easily broken or damaged, and hinders packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

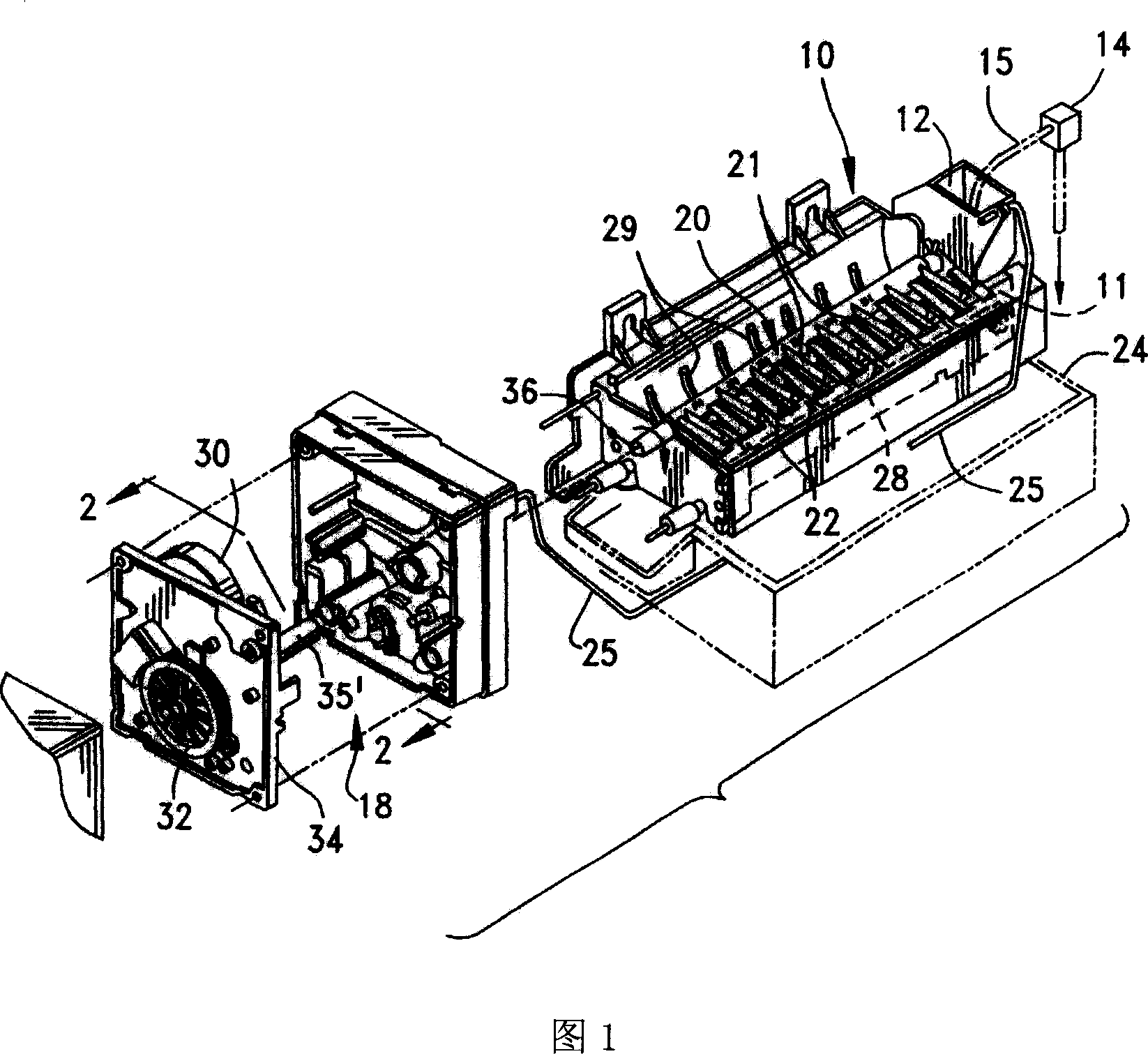

[0024] Referring more specifically to FIG. 1 , there is a schematic diagram of an exemplary ice maker 10 according to the present invention. It can be understood that the basic structure and operation of the ice maker has been disclosed in the aforementioned US Patent No. 5,261,248, the disclosure of which is incorporated into the present invention for reference and will not be repeated here.

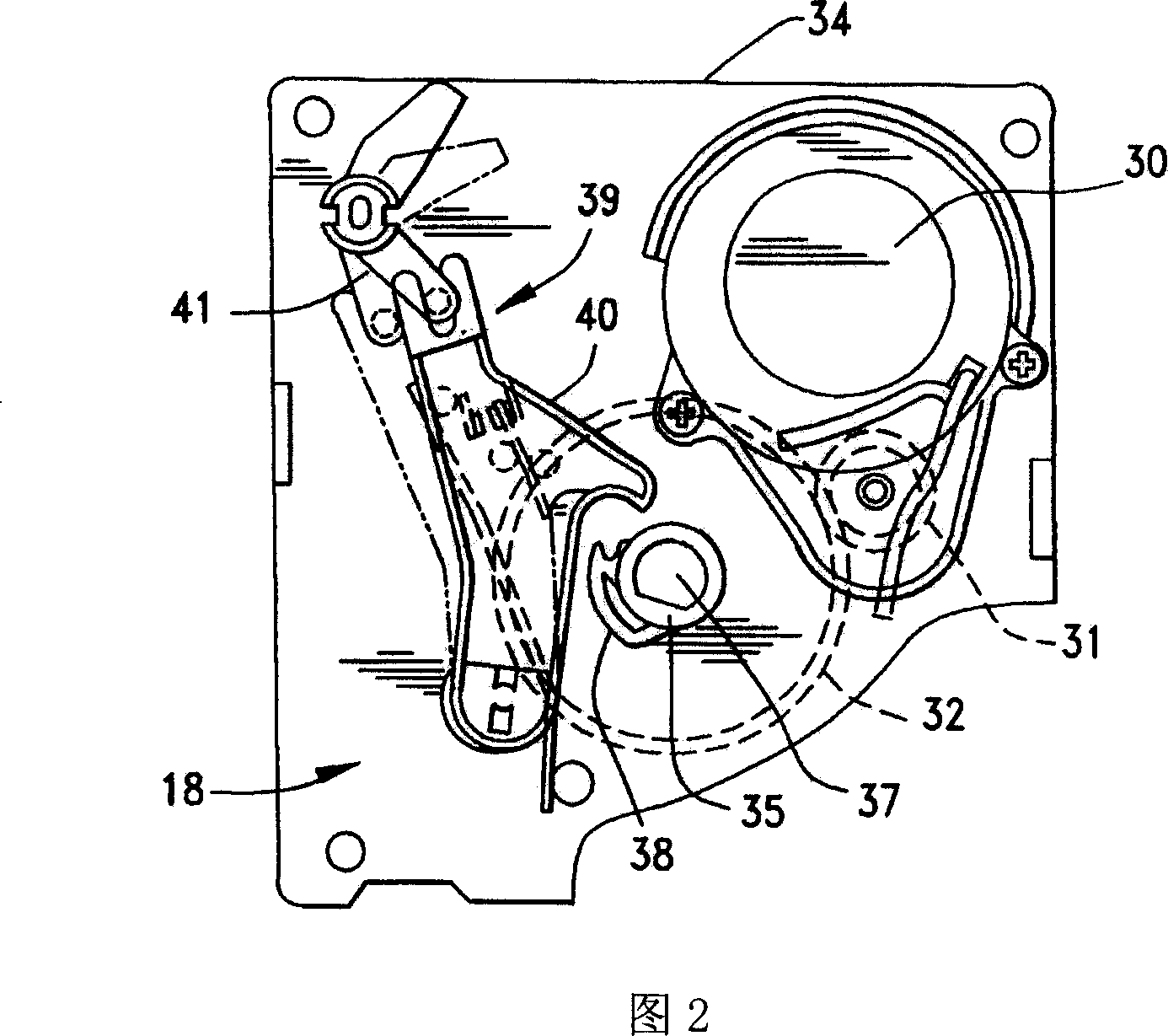

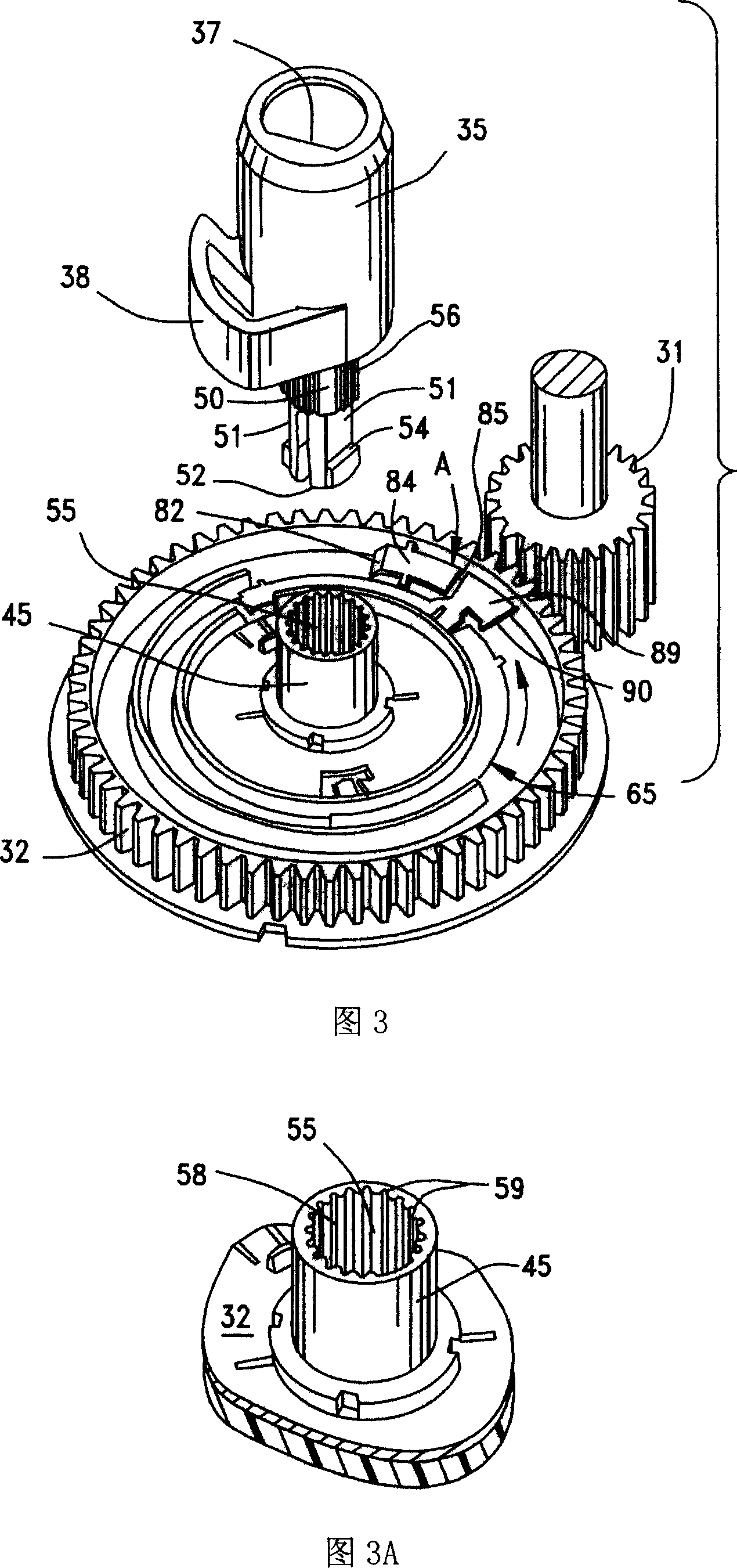

[0025] The exemplary ice making machine depicted in FIG. 1 includes a mold 11 into which water is delivered to form ice bodies through a fill distributor 12 connected by a water supply line 15 to a solenoid valve 14 . Solenoid valve 14 may in turn be connected to a suitably pressurized water supply. The ice maker 10 further includes a control module 18 located in front of the mold 11 for operating the ice ejector 20 to remove the ice mass from the mold upon completion of the water freezing cycle in the mold 11. The ice ejector 20 has a plurality of radial ejector arms 21 which rotatabl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap