Dynamic type polymer lithium ion power supply and its manufacturing process

A lithium-ion battery and polymer technology, applied in the direction of electrochemical generators, circuits, electrical components, etc., can solve the problems of limiting the application and development of lithium-ion power batteries, hindering them, and preventing cracking, enhancing reliability, and avoiding damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

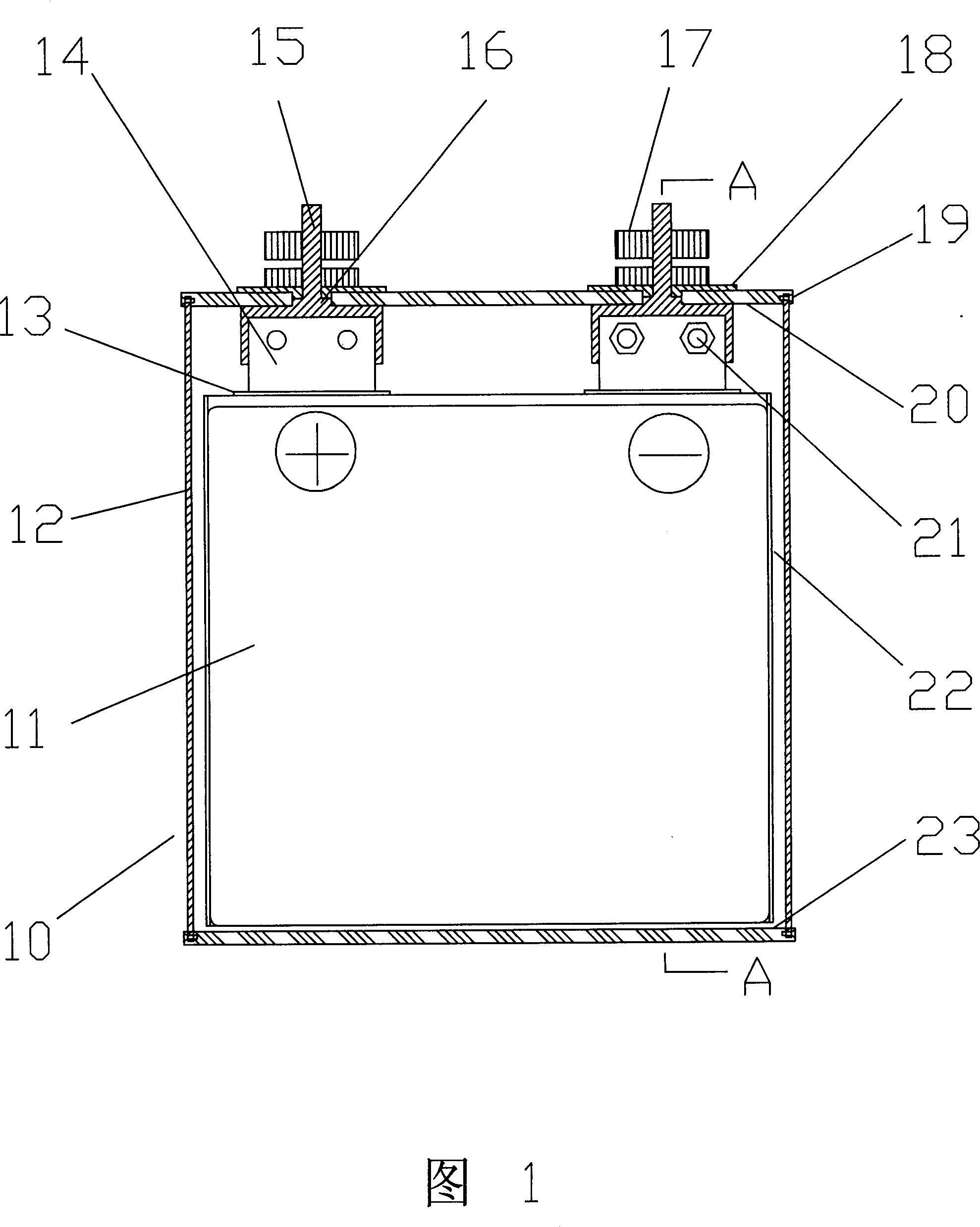

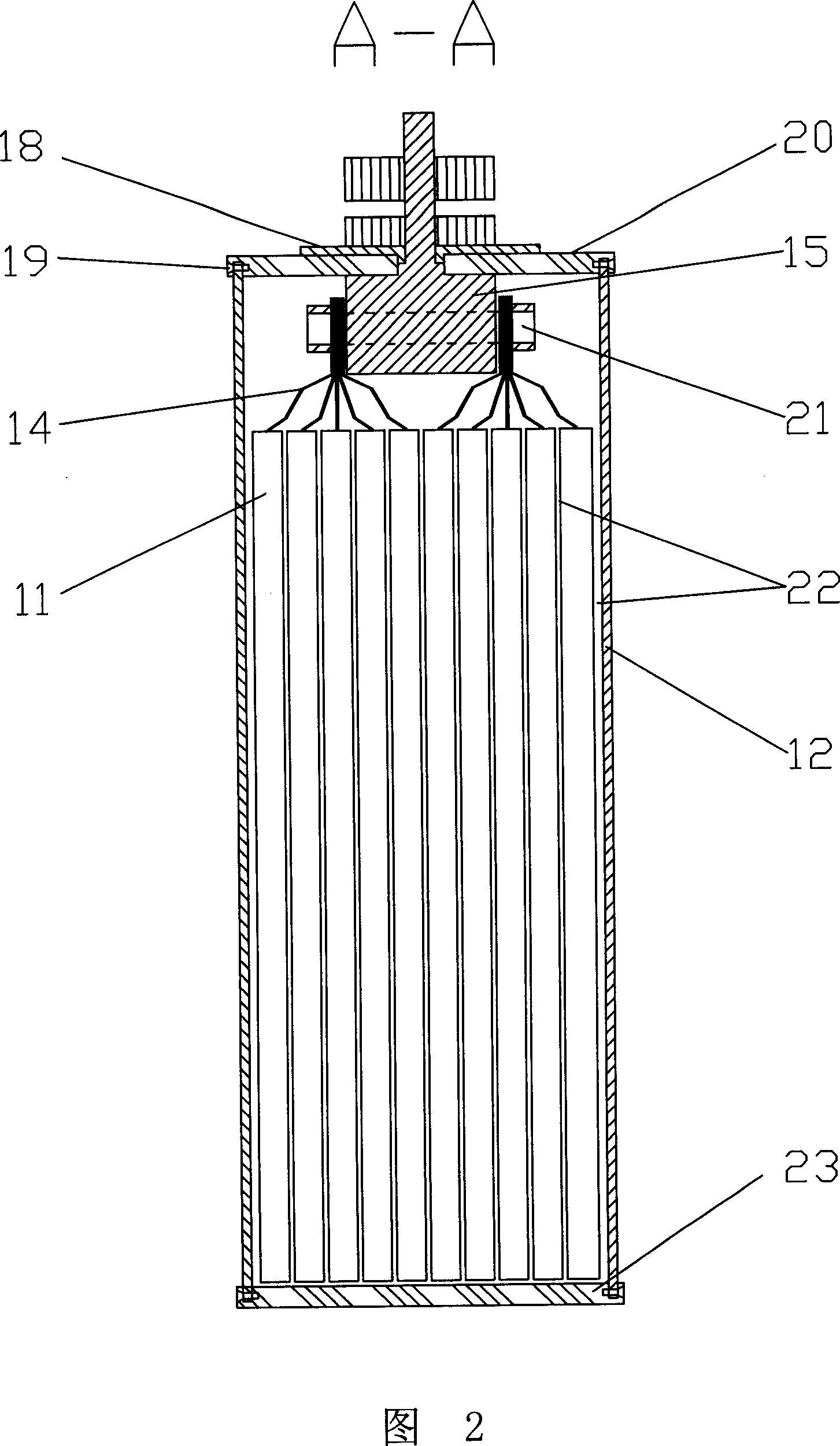

Image

Examples

example 1

[0047] (1) Preparation of negative electrode:

[0048] (1.1) Dissolve 1560 grams of polyvinylidene fluoride in N-methyl-2-pyrrolidinedione, first add 20 grams of oxalic acid, then add 500 grams of acetylene black, and finally add 22000 grams of graphite powder. After high-speed stirring, vacuum or static degassing, the slurry-like negative electrode slurry is made.

[0049] (1.2) Coating film: According to the requirements of battery product design, the negative electrode slurry is evenly coated on the front and back surfaces of the 16 micron thick copper foil. The solvent N-methyl-2-pyrrolidinedione was dried and removed at 120° C., and the thickness of the electrode strip was controlled at 160±10 microns.

[0050] (1.3) Rolling: Roll the negative pole piece to a specified thickness under a certain pressure, and control the film density and porosity of the pole piece film. The thickness of the electrode strip after rolling is controlled at 110±5 microns.

[0051] (1.4) She...

example 2

[0066] (1) Preparation of negative electrode:

[0067] (1.1) Dissolve 1,560 grams of polyvinylidene fluoride in N-methyl-2-pyrrolidinedione, first add 20 grams of oxalic acid, then add 500 grams of acetylene black, and finally add 35,000 grams of amorphous tin Lithium composite oxide SnLi ρ P B χ o ψ . After high-speed stirring, vacuum or static degassing, the slurry-like negative electrode slurry is made.

[0068] (1.2) Coating film: According to the requirements of battery product design, the negative electrode slurry is evenly coated on the front and back surfaces of the 16 micron thick copper foil. The solvent N-methyl-2-pyrrolidinedione was dried and removed at 120° C., and the thickness of the electrode strip was controlled at 150±10 microns.

[0069] (1.3) Rolling: Roll the negative pole piece to a specified thickness under a certain pressure, and control the film density and porosity of the pole piece film. The thickness of the electrode strip after rolling is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com