Double-sensor laser visual measuring system calibrating method

A three-dimensional measurement and dual-sensor technology, applied in the field of measurement, can solve problems such as low calibration efficiency and complicated operation process, and achieve high calibration accuracy and measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

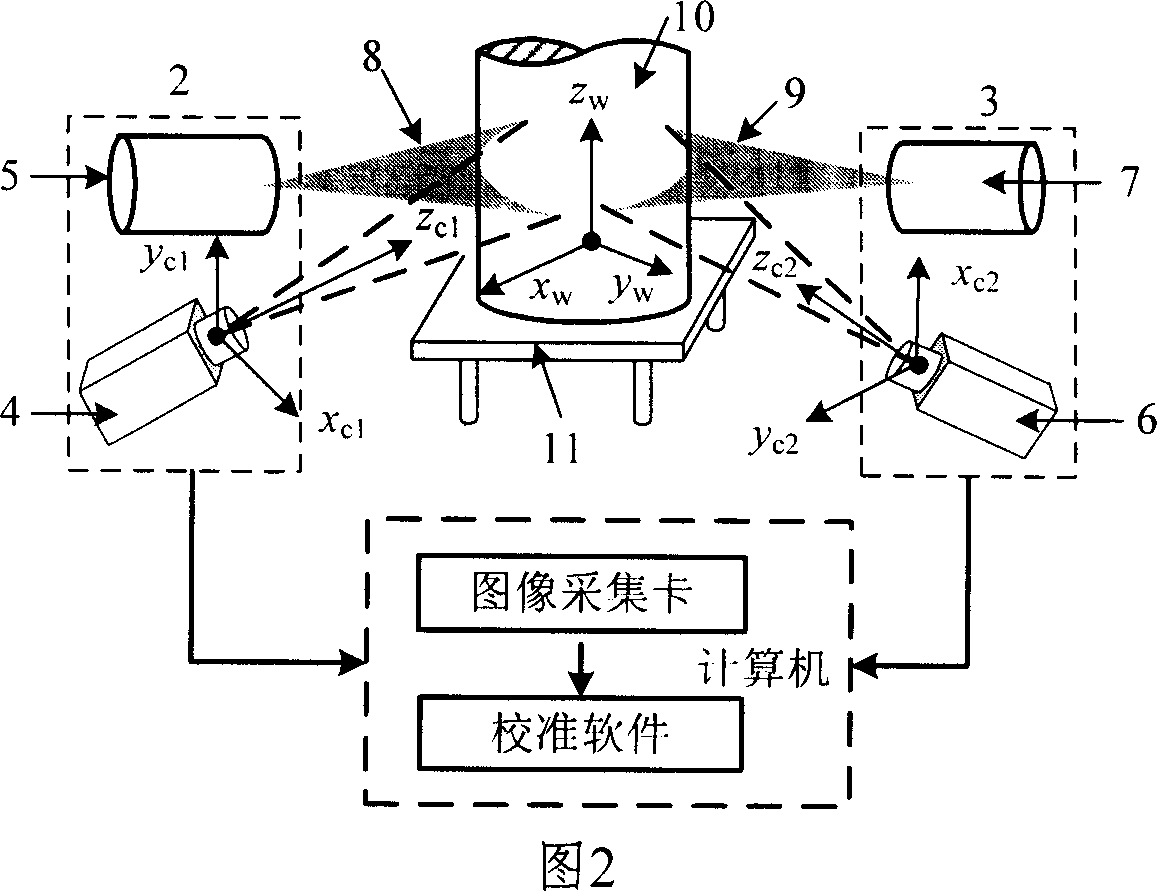

[0078] Two Mintron MS368P CCD cameras, Japanese Seiko lenses with focal lengths of 12mm and 16mm, and two line structured light projectors form a dual-sensor laser vision three-dimensional measurement system. The working distance of the sensor is within 600mm.

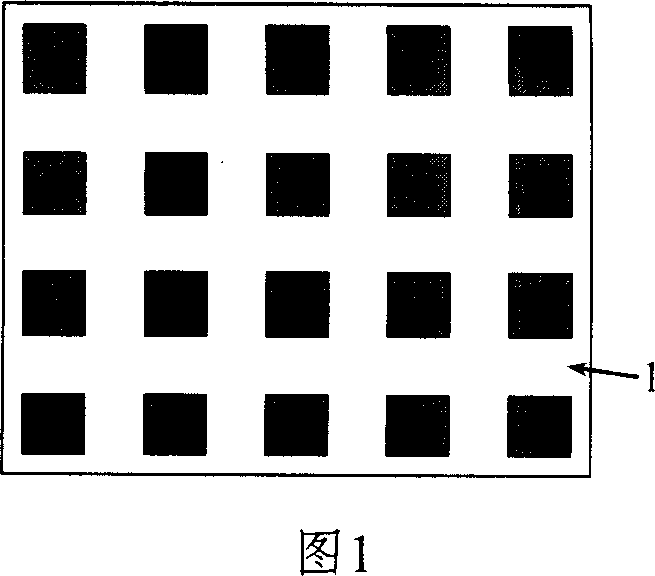

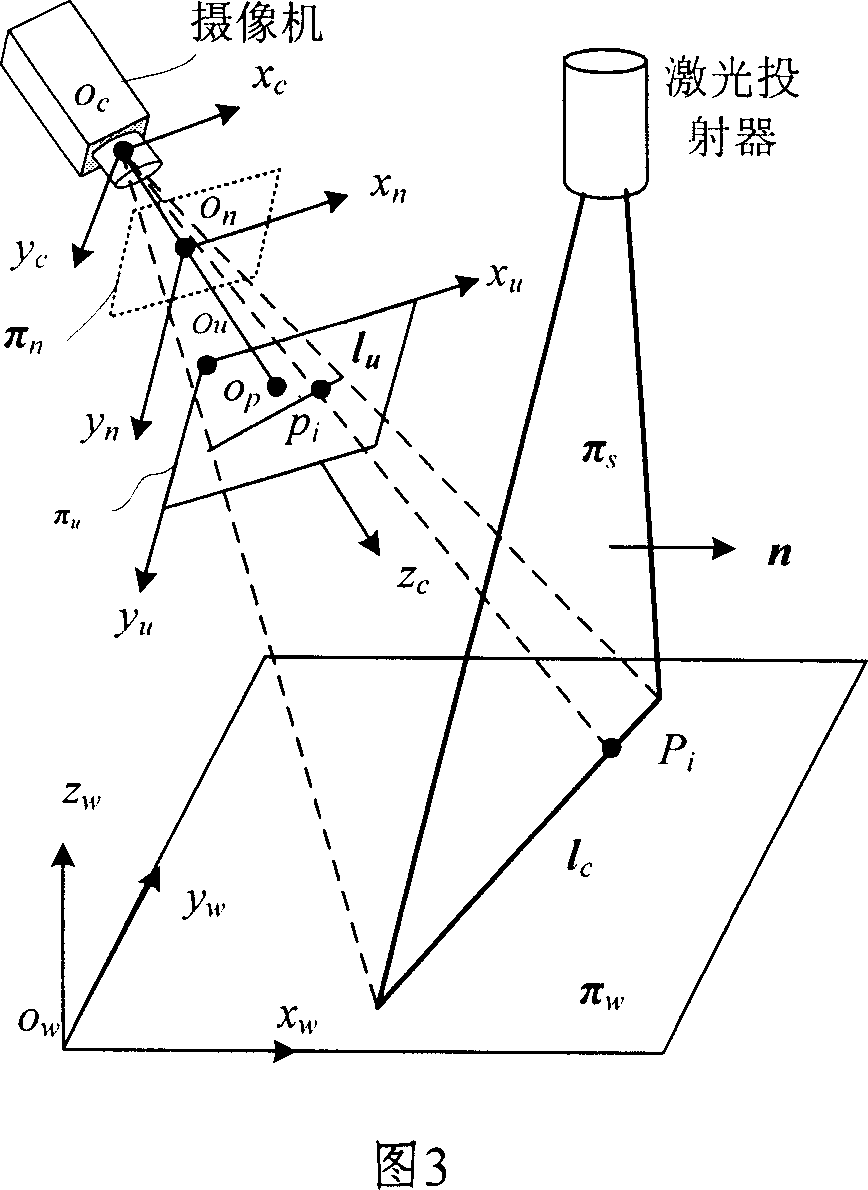

[0079] According to the steps described above, the model parameters of the dual-sensor laser vision three-dimensional measurement system were calibrated using the plane target shown in Figure 1. Within the measurement space range of each sensor, move 5 positions randomly, and use the image acquired by the CCD camera to extract feature points to calibrate the internal parameters of the camera. Turn on the power of the laser projector, ensure that the projected light strips pass through the characteristic area of the target, move three positions randomly to obtain an image, and use the method described above to obtain control points on the light plane to calibrate the two light planes. The plane target is placed in the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com