Three-phase wound-rotor induction motor

A technology of induction motors and wound rotors, applied in the field of motors, can solve problems such as complex manufacturing process, influence on motor operation performance, motor damage, etc., and achieve the effect of simplifying the mechanical structure of the rotor and eliminating hidden troubles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

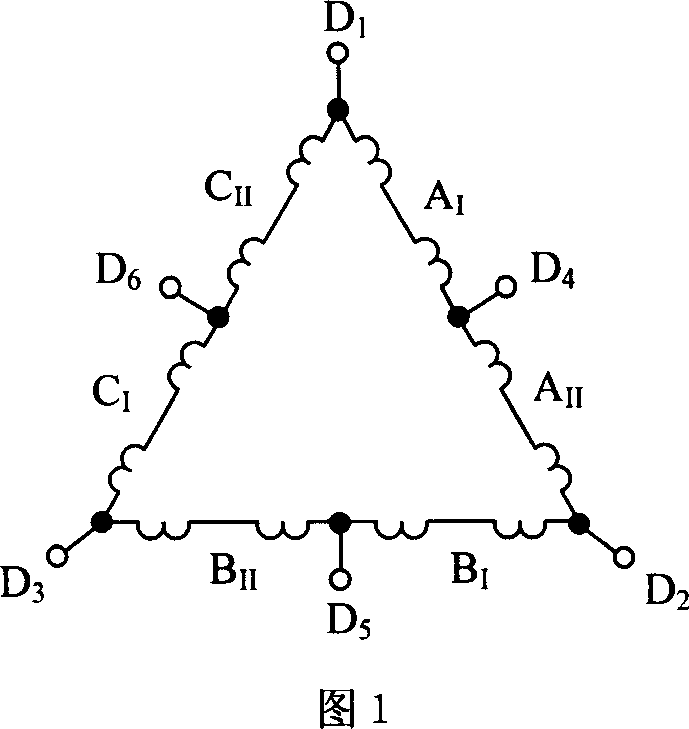

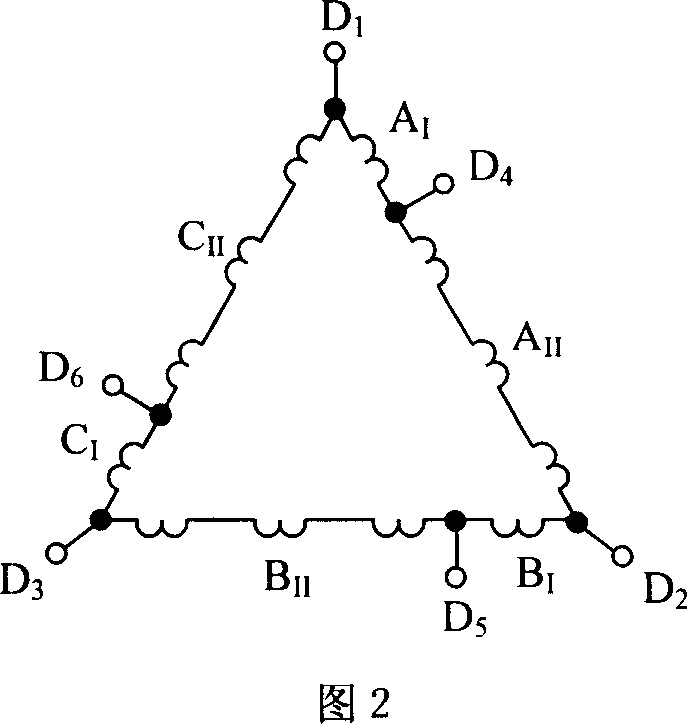

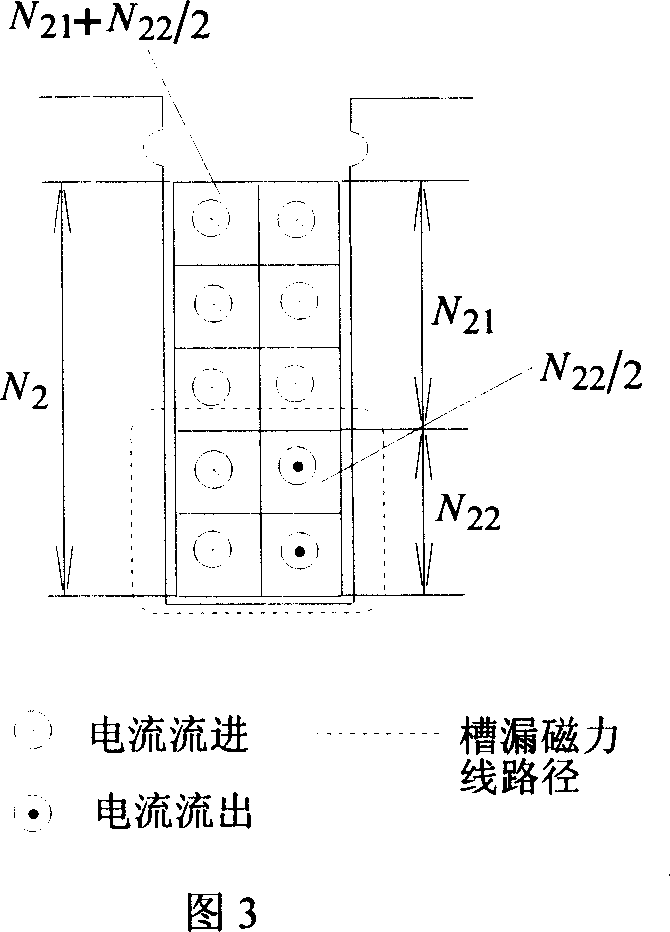

[0015] As shown in Figure 1, a set of three-phase stator windings with a number of pole pairs p and a triangular connection mode are placed on the stator of the present invention. There are six outlet terminals in total, three of which are connected to the three-phase power supply during normal operation. Terminal D 1 、D 2 、D 3 , and the other three are the middle taps of each phase winding, which are connected to the three-phase power outlet terminal D when starting. 4 、D 5 、D 6 , then the three-phase winding has both the number of pole pairs p and the number of pole pairs q. The switch device is used to switch different outlets to switch between the two working states of starting and normal operation. The coils in each phase winding are connected in series, where the center tap D of each phase winding 4 、D 5 、D 6 The coil of each phase winding is divided into two parts, and the three-phase winding is divided into six parts, as shown in Figure 1, respectively marked a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com