Articulation between a wiper arm and a wiper arm mounting, and a windscreen wiper having such an articulation

A brush rod holder and joint technology, which is applied in the direction of vehicle cleaning, transportation and packaging, vehicle maintenance, etc., can solve the problems of loose brush rod, complex structure and/or manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

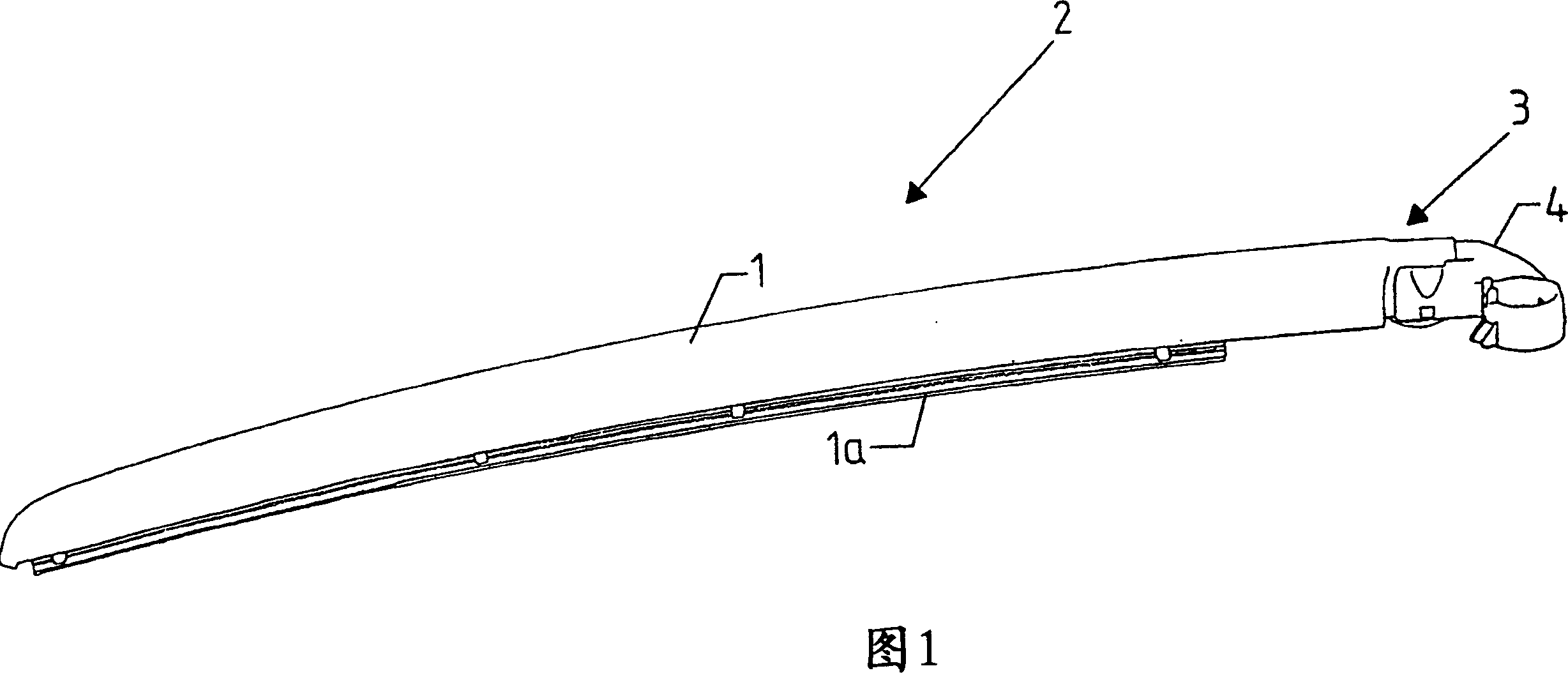

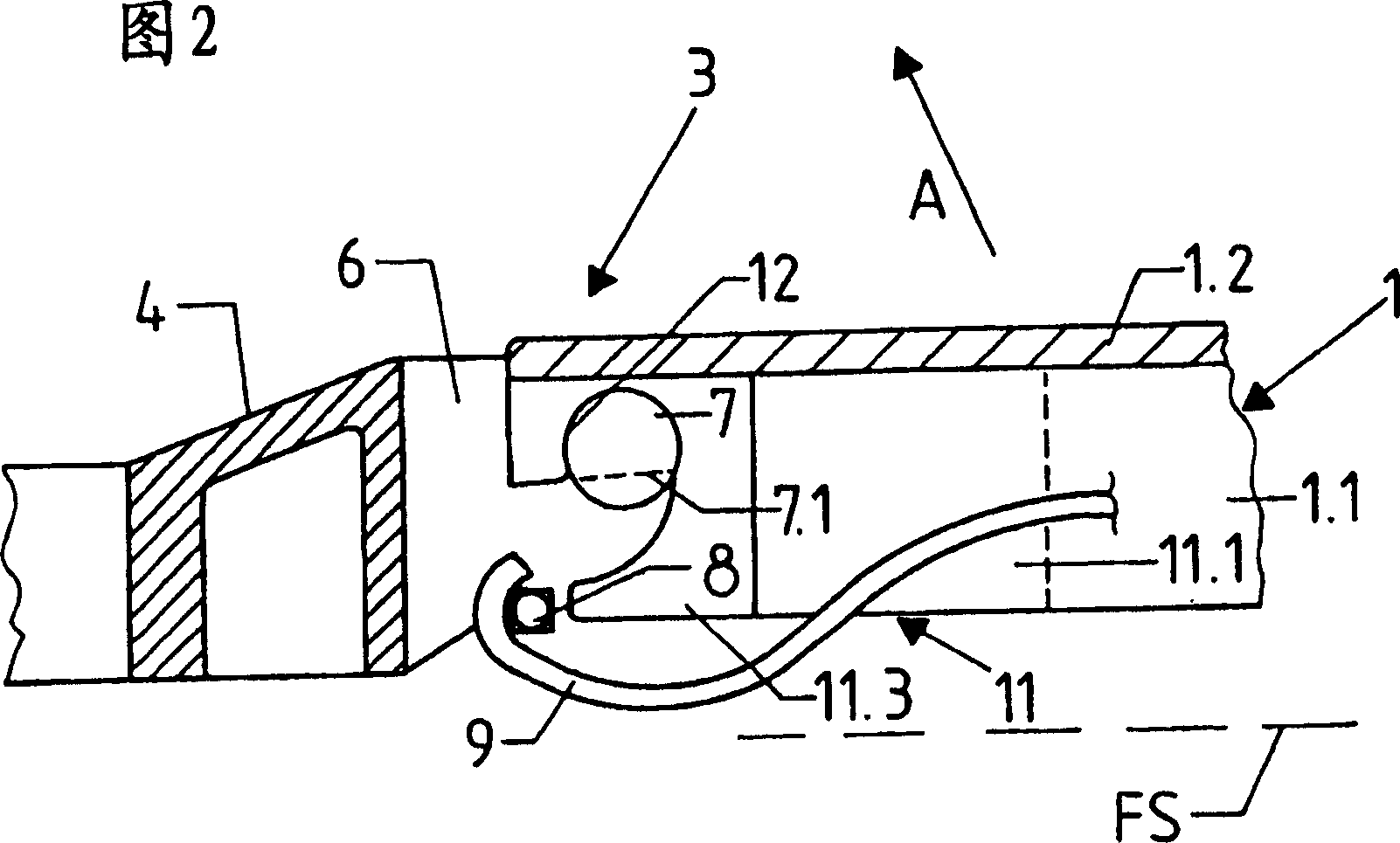

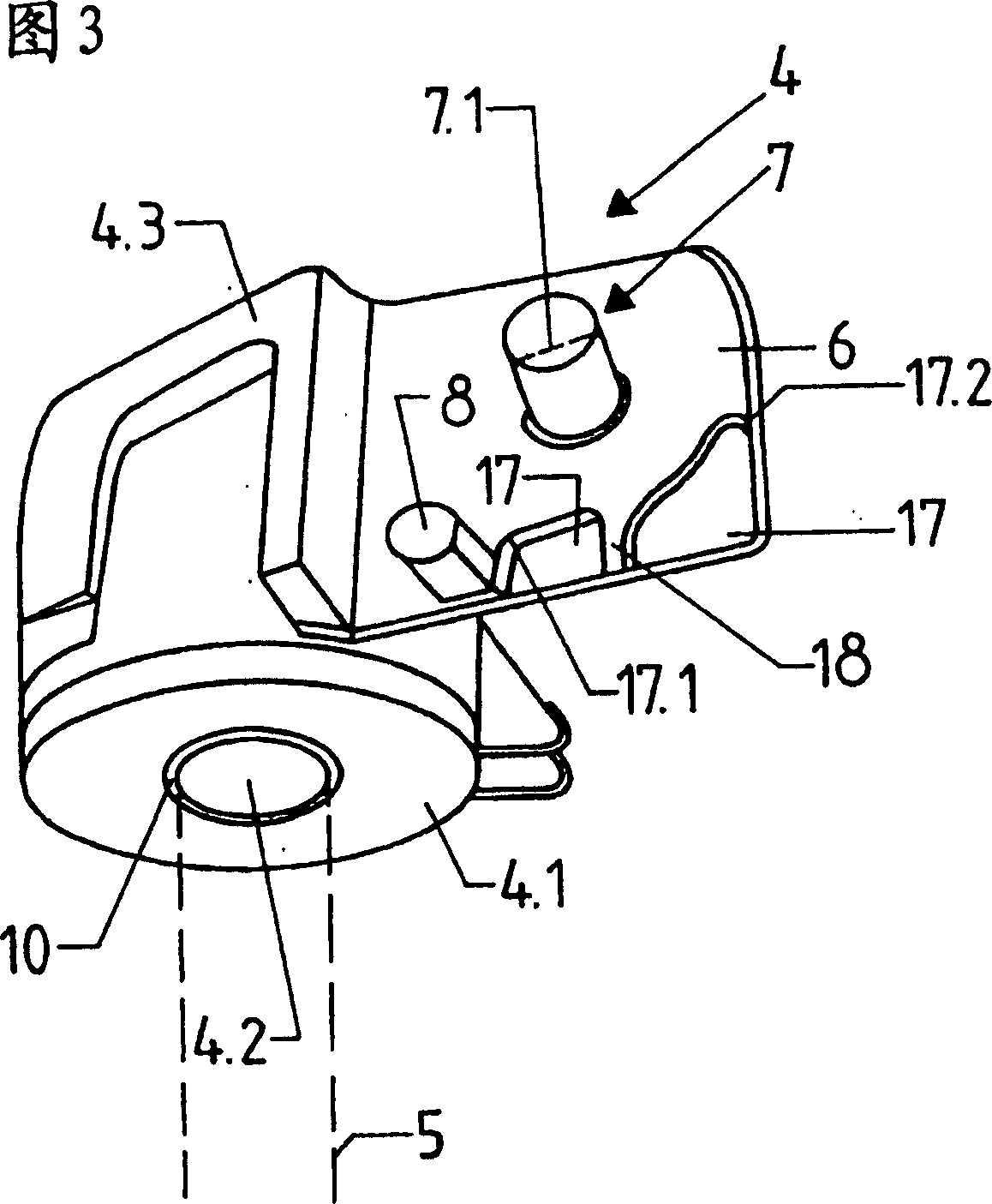

[0015] In FIG. 1 is a brush bar 1 of a brush arm 2 of a wiper device for a motor vehicle window FS, such as a motor vehicle windshield or rear window, which is schematically represented in FIG. 2 by dashed lines . The brush bar 1 is hingedly connected via a joint 3 to the brush bar frame 4, which is at the same time an integral part of the brush arm 2 and which can be fastened as a fastening part for the brush arm 2, indicated by the dotted line 5 in FIG. 3 and used for the brush bar 1 Reversible driven wiper shaft 5 with swivel movement.

[0016] The brush bar 1 can be swiveled via the joint 3 from its working position shown in FIG. The brush blade 1a that is arranged on the entire length of the brush bar 1 is close to the automobile window glass FS. 1 is pivoted away from the vehicle window FS and is oriented with its longitudinal extension obliquely to the plane of the vehicle window.

[0017] In the illustrated embodiment, the brush holder 4 essentially comprises a slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com