Shut-off and reversing valve

A technology for distributing valve and switching control, applied in multi-port valve, valve device, transportation and packaging, etc., can solve the problem of not providing independence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

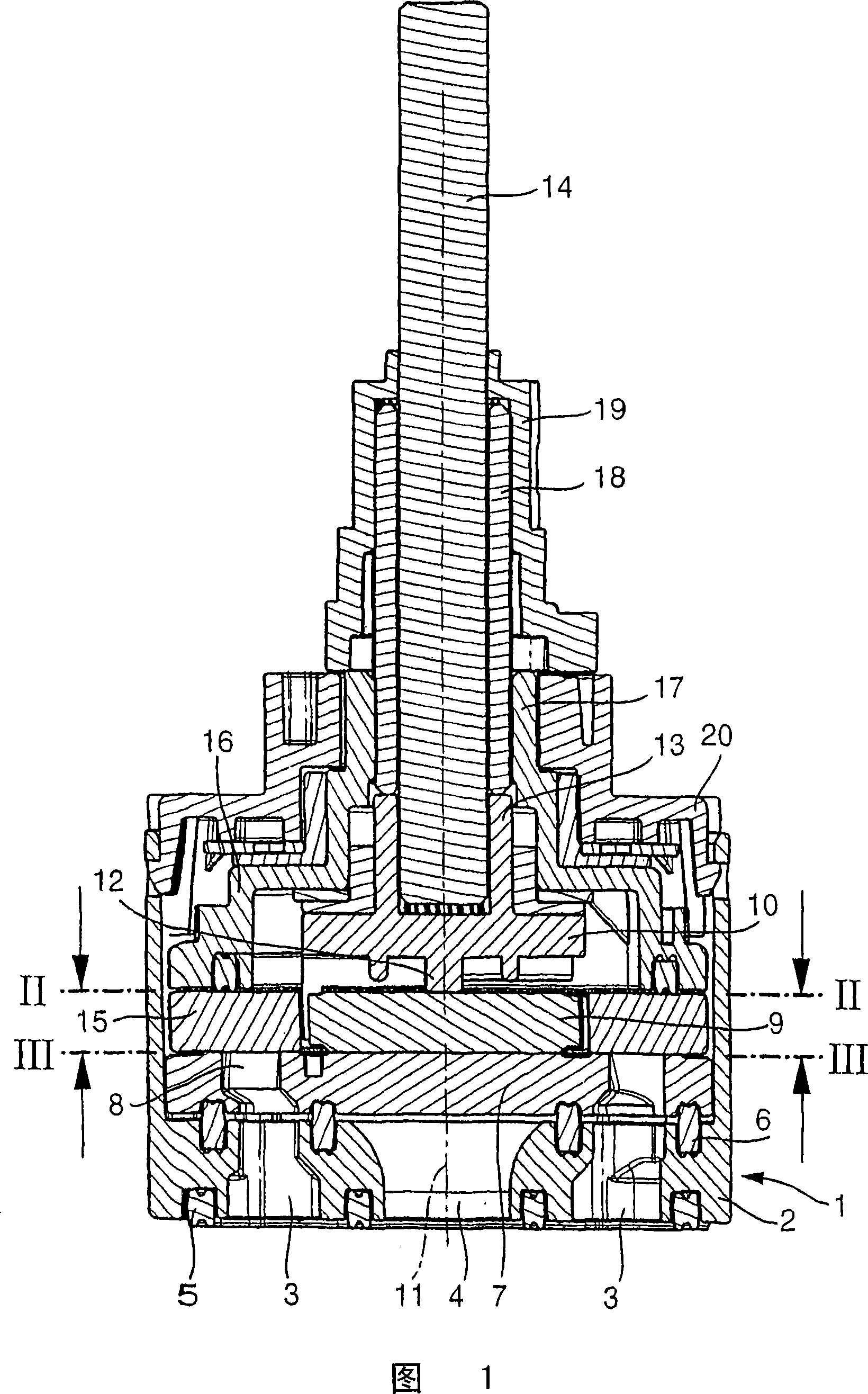

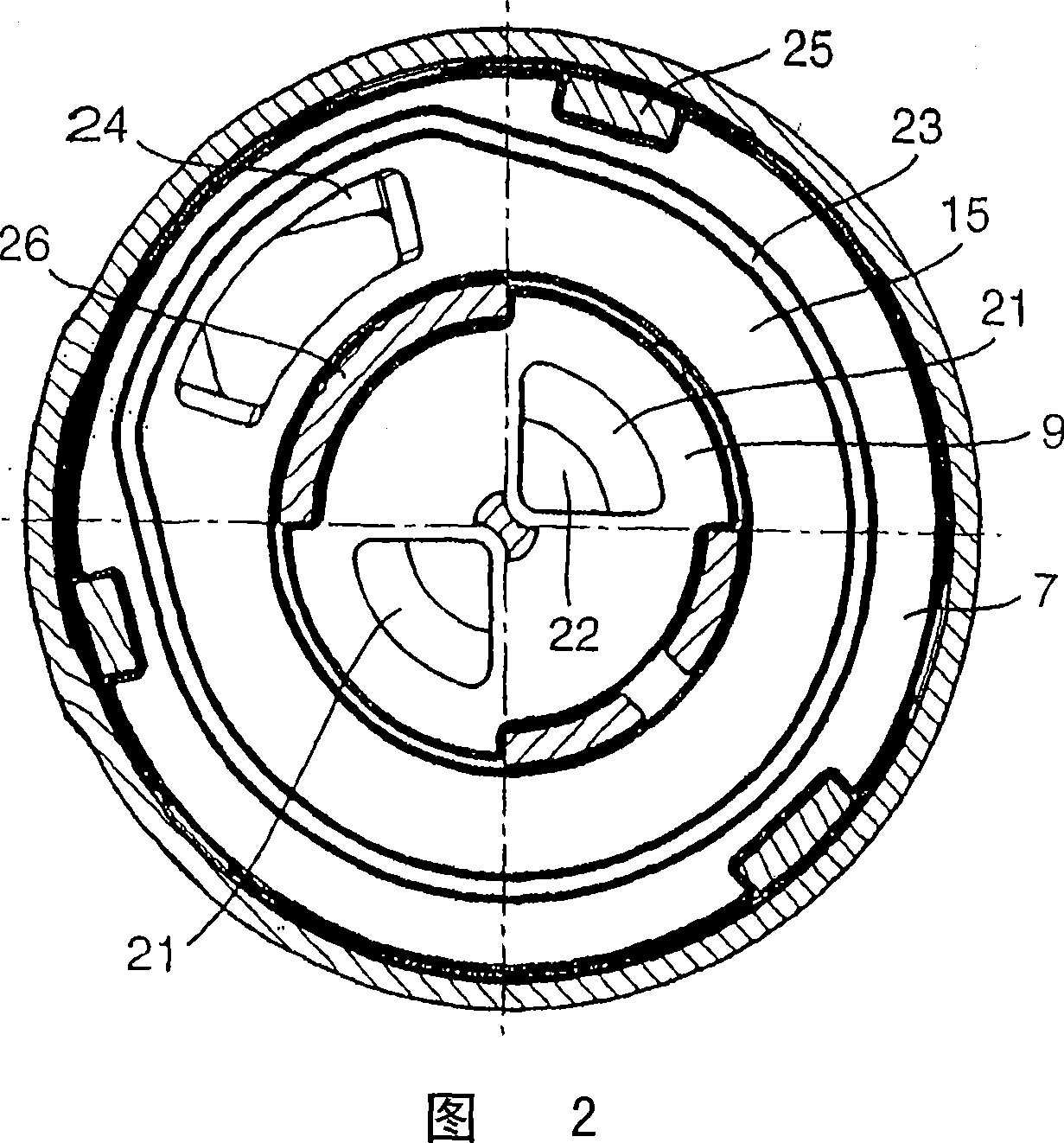

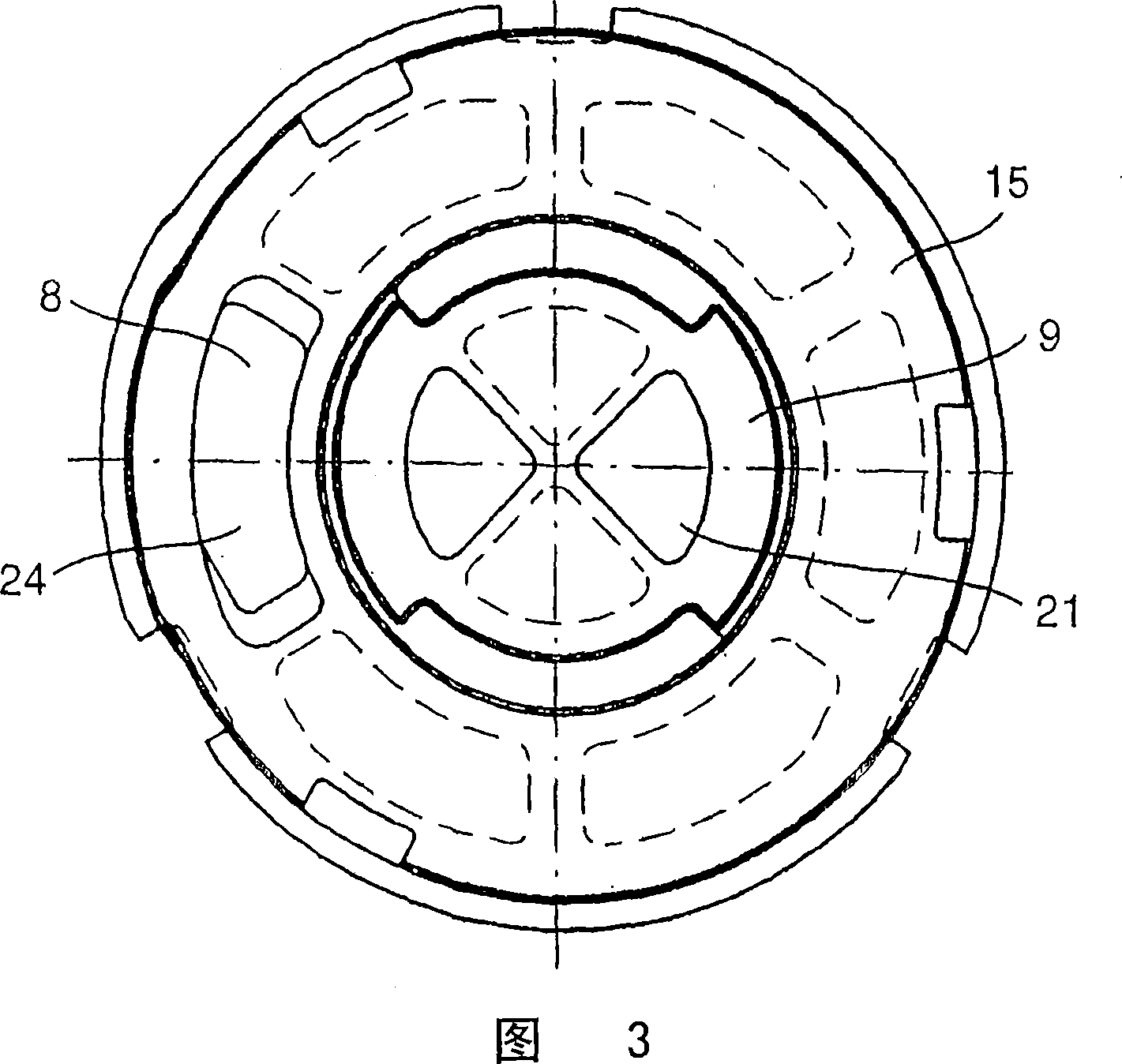

[0022] The cleaning valve shown in axial section in FIG. 1 comprises a valve housing 1 which is closed by means of a base 2 in its bottom part. The base 2 comprises a plurality of outlet openings 3, and an inlet opening 4 in the middle. The valve housing 1 is inserted onto a fitted housing in which corresponding channels are provided. For sealing against the fitted housing, a seal 5 is provided.

[0023] On the base 2 of the valve housing 1 , a fixed ceramic disc 7 is arranged above the seal 6 , which ceramic disc is often also referred to as a distribution disc. This distribution plate 7 has a passage opening 8 which communicates with the water outlet 3 . The distribution plate 7 is also characterized by two central cutouts, which communicate with the water inlet 4 . These intermediate cutouts are not visible in the cross-section of FIG. 1 .

[0024] Above the distribution disc 7, a first movable control disc 9 is arranged in the middle. This movable control disk 9 can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com