Metal halide lamp, lighting device for metal halide lamp and headlight

A technology for metal halide lamps and headlights, applied in lighting devices, fixed lighting devices, discharge lamps, etc., can solve the problems of slow evaporation of metal halides and inability to obtain high vapor pressure of mercury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

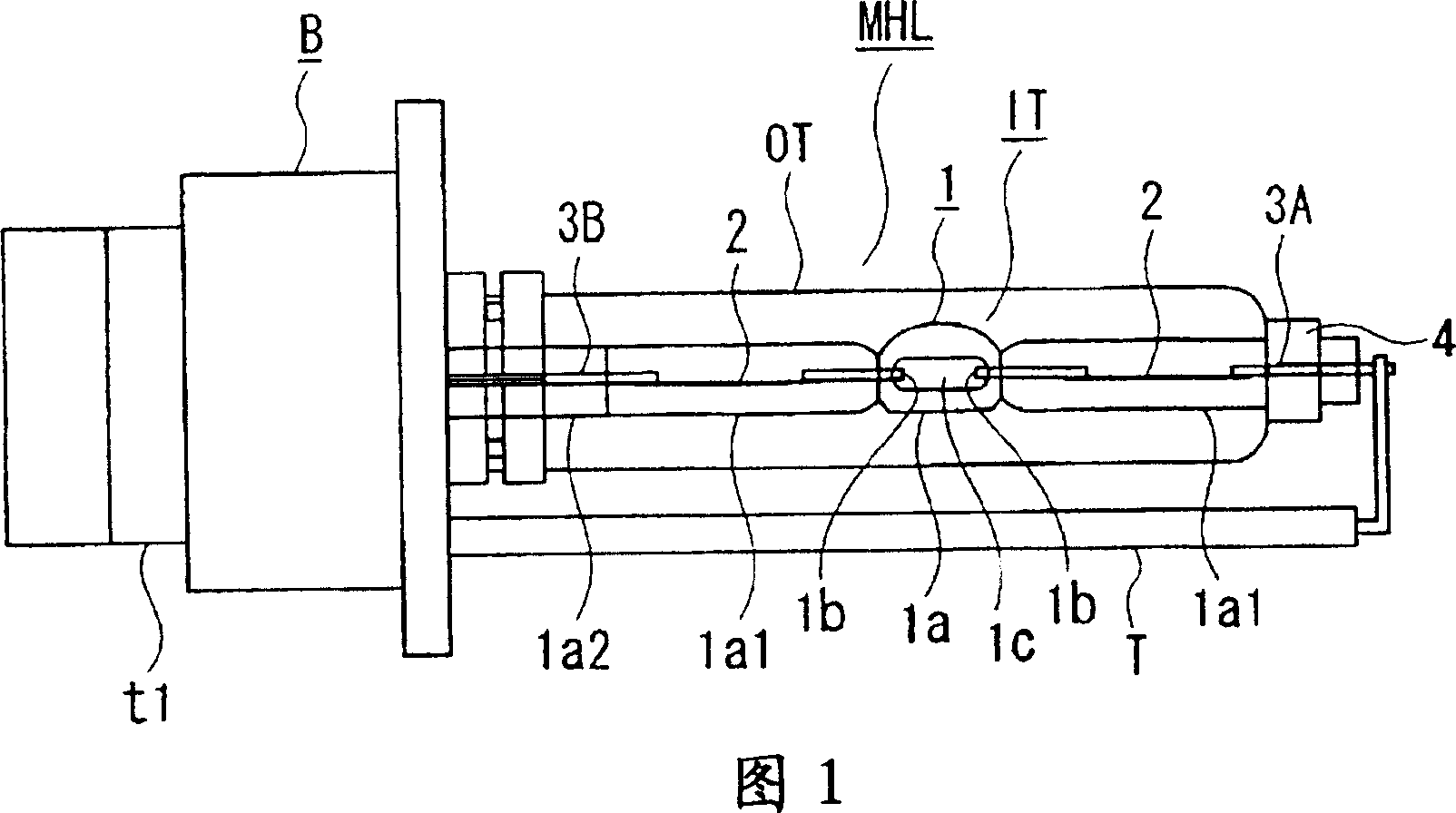

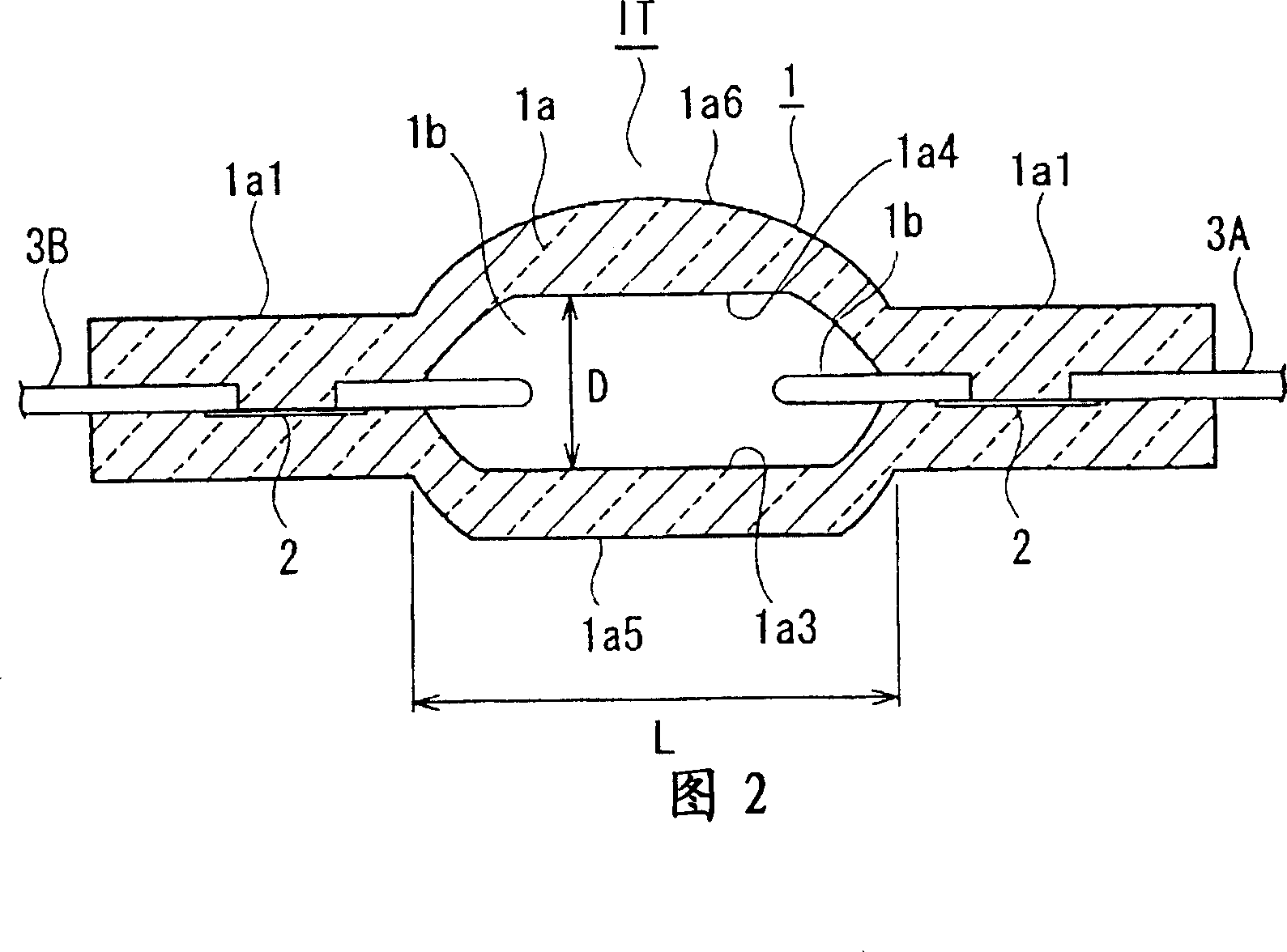

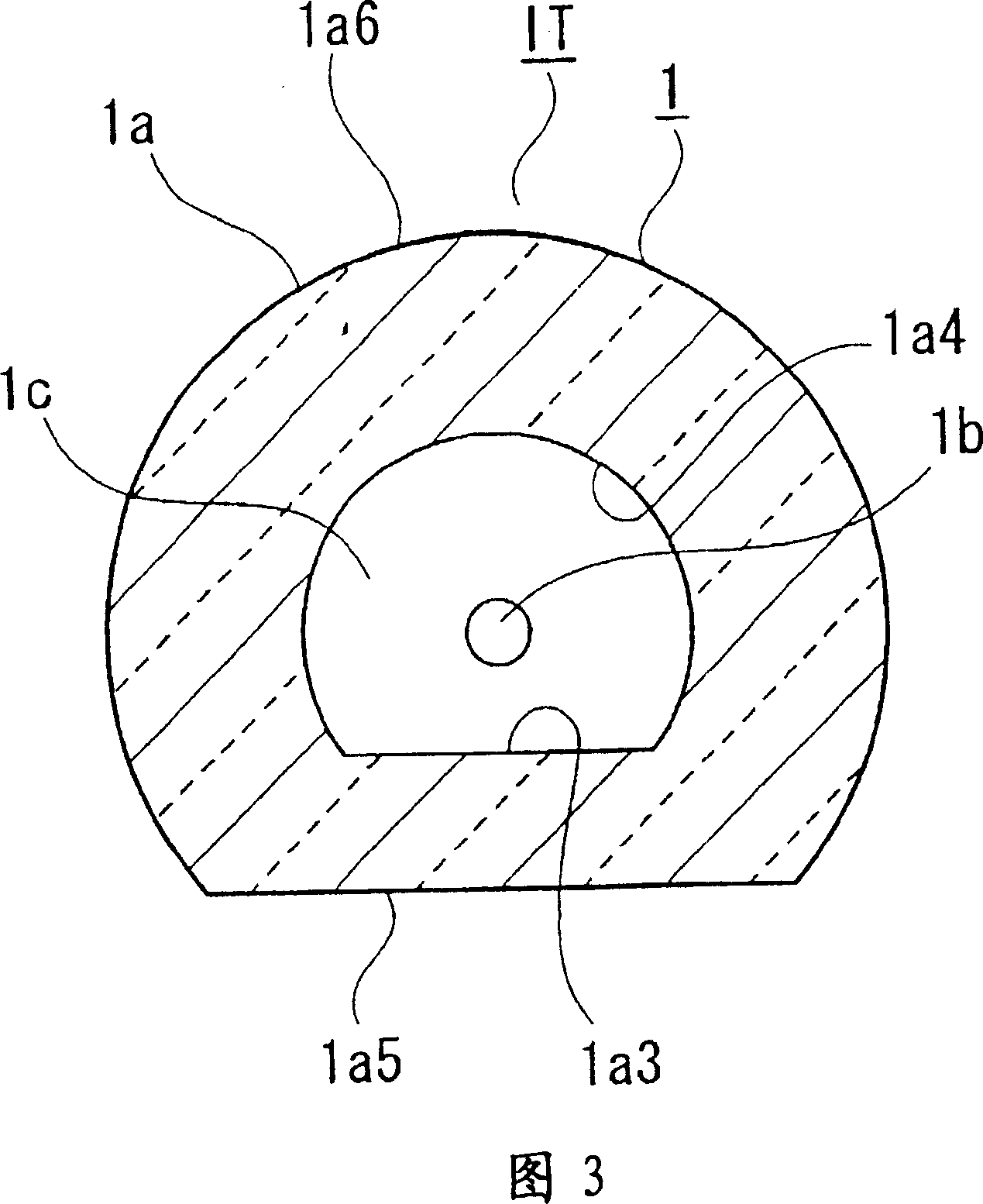

[0076] Light-transmitting airtight container 1: the inner volume of the inner space is 0.020cc, and the distance D2.3mm

[0077] Inner diameter 2.6mm, enclosure length 7.0mm, enclosure outer diameter

[0078] 6.0mm, D / L0.33

[0079] Distance between electrodes: 4.2mm

[0080] Discharge medium: metal halide ScI 3 -NaI-ZnI 2 -InI-CsI,

[0081] Total 0.5mg, rare gas Xe10atm

[0082] Input power immediately after starting: 85W

[0083] Input current immediately after starting: 2.8A

[0084] Lamp voltage when stable: 42V

[0085] Steady lamp current: 0.8A

[0086] Steady lamp power: 35W

[0087] Luminous flux when starting for 4 seconds: 1370lm

[0088] [Comparative example]

[0089] Light-transmitting airtight container 1: the internal volume of the internal space is 0.020cc, the inner diameter is 2.6mm, and the surrounding part

[0090] Length 7.0mm, outer diameter of surrounding part 6.0mm

[0091] ...

Embodiment 2

[0120] Metal covering body SC: constituted by a coil body as an example.

[0121] The diameter of the coil is 0.07mm, the pitch of the coil is 100%, the length of the electrode axis direction is 5.5mm, and the length of the electrode axis direction on the sealing metal foil 2 is 1.5mm

[0122] The diameter of the shaft portion of the electrode 1b is 0.3 mm in the sealing portion and 0.38 mm in the discharge space.

[0123] Light-transmitting airtight container 1: The inner diameter of the surrounding portion 1a is 2.6 mm, the outer diameter is 6.0 mm, and the maximum length in the longitudinal direction is 6.6 mm.

[0124] Discharge medium: the metal halide is scandium iodide-sodium iodide-zinc iodide 0.5mg, the rare gas is xenon about 11 atmospheres, and it does not contain mercury at all.

[0125] Fig. 6 shows the length L in the second embodiment of the present invention E (mm) graph versus chromaticity change. This graph is obtained by changing the length of the metal cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com