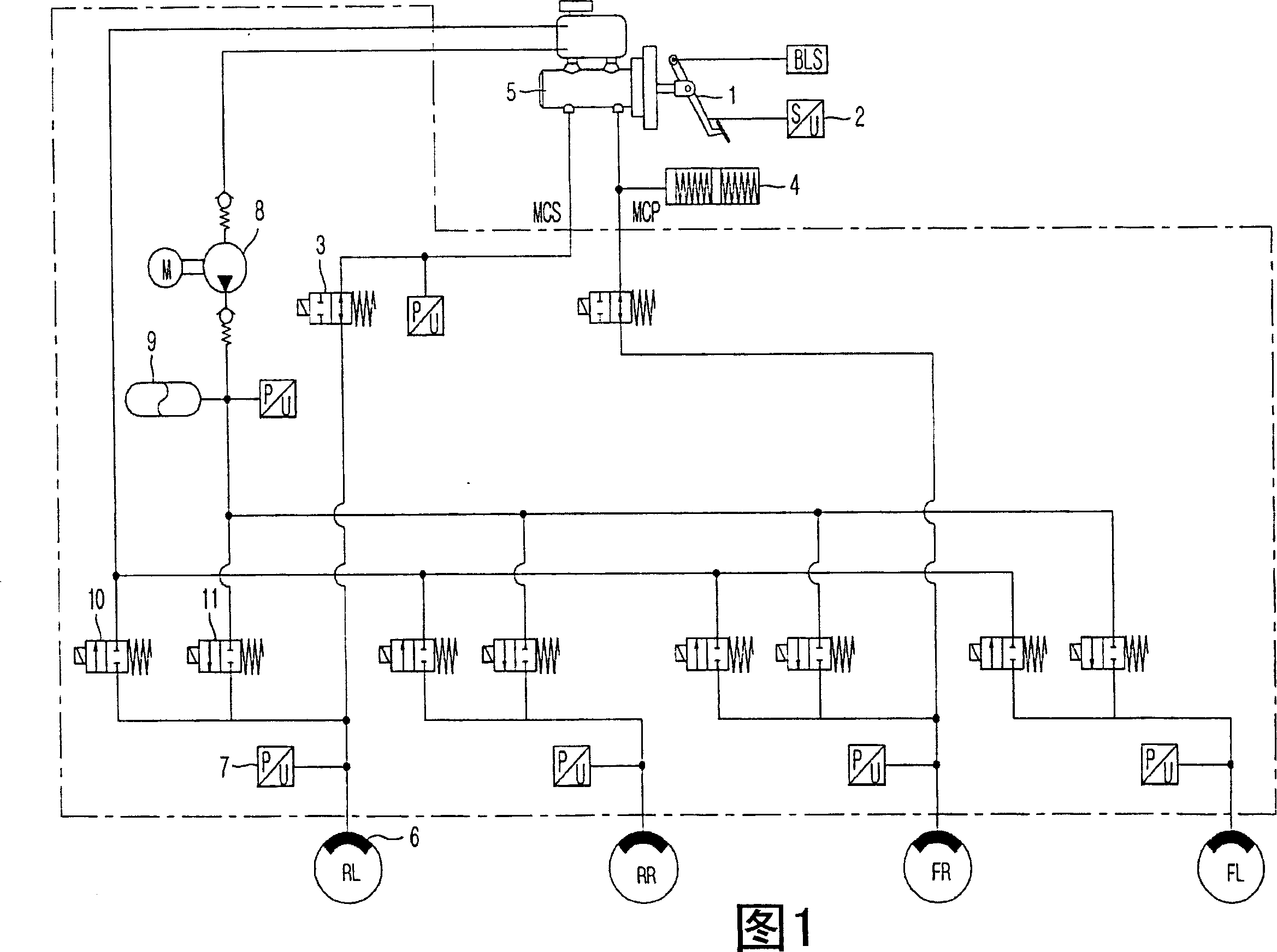

Electro-hydraulic brake system

A hydraulic braking and electronic technology, applied in the direction of brakes, brake components, control valves and air release valves, etc., can solve the problems of EHB system reliability and durability deterioration, master cylinder installation, low use versatility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

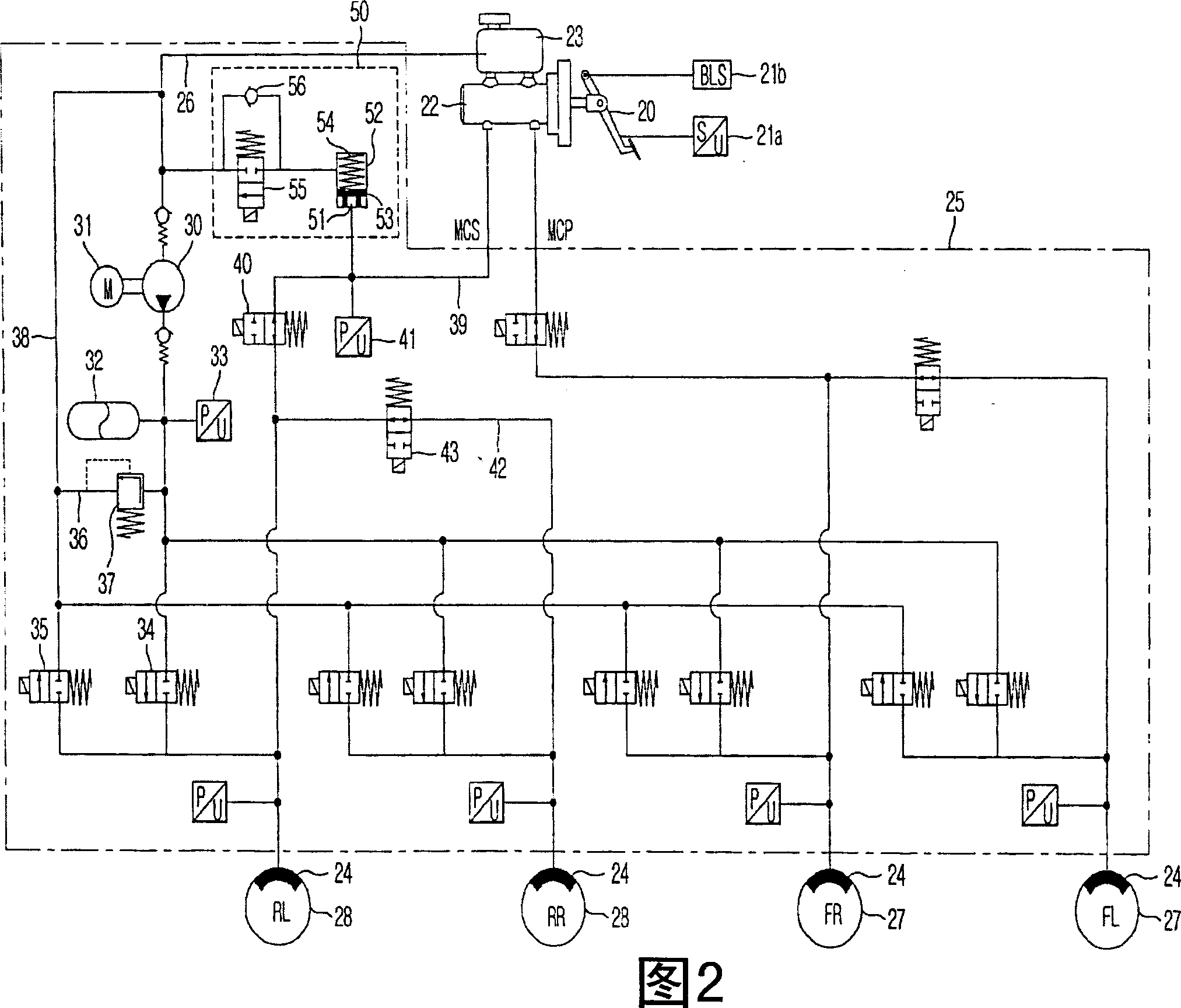

[0021] Reference will now be made in detail to the exemplary embodiments of the present invention, examples of which are illustrated in the drawings, wherein like reference numerals refer to like elements throughout. The embodiments are described below to explain the present invention by referring to the figures.

[0022] Fig. 2 is a schematic diagram of a hydraulic circuit of an EHB system according to a preferred embodiment of the present invention.

[0023] Referring to FIG. 2, the electronic hydraulic braking system (hereinafter referred to as "EHB" system) according to the present invention includes a brake pedal 20 for being operated by the driver of the vehicle when performing a braking operation, for receiving a master cylinder 22 that transmits the force, an oil reservoir 23 located on top of the master cylinder 22 and for storing oil therein, a wheel cylinder 24 that receives oil released from the oil reservoir 23 and is used for braking the respective brake wheels 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com