Electronic defrost timer for mechanical refrigerator

A timer and electronic technology, applied in defrosting, electronic switches, applications, etc., can solve the problems of material and personal damage, reduced rotation speed of meshing gears, manpower, resources and management costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

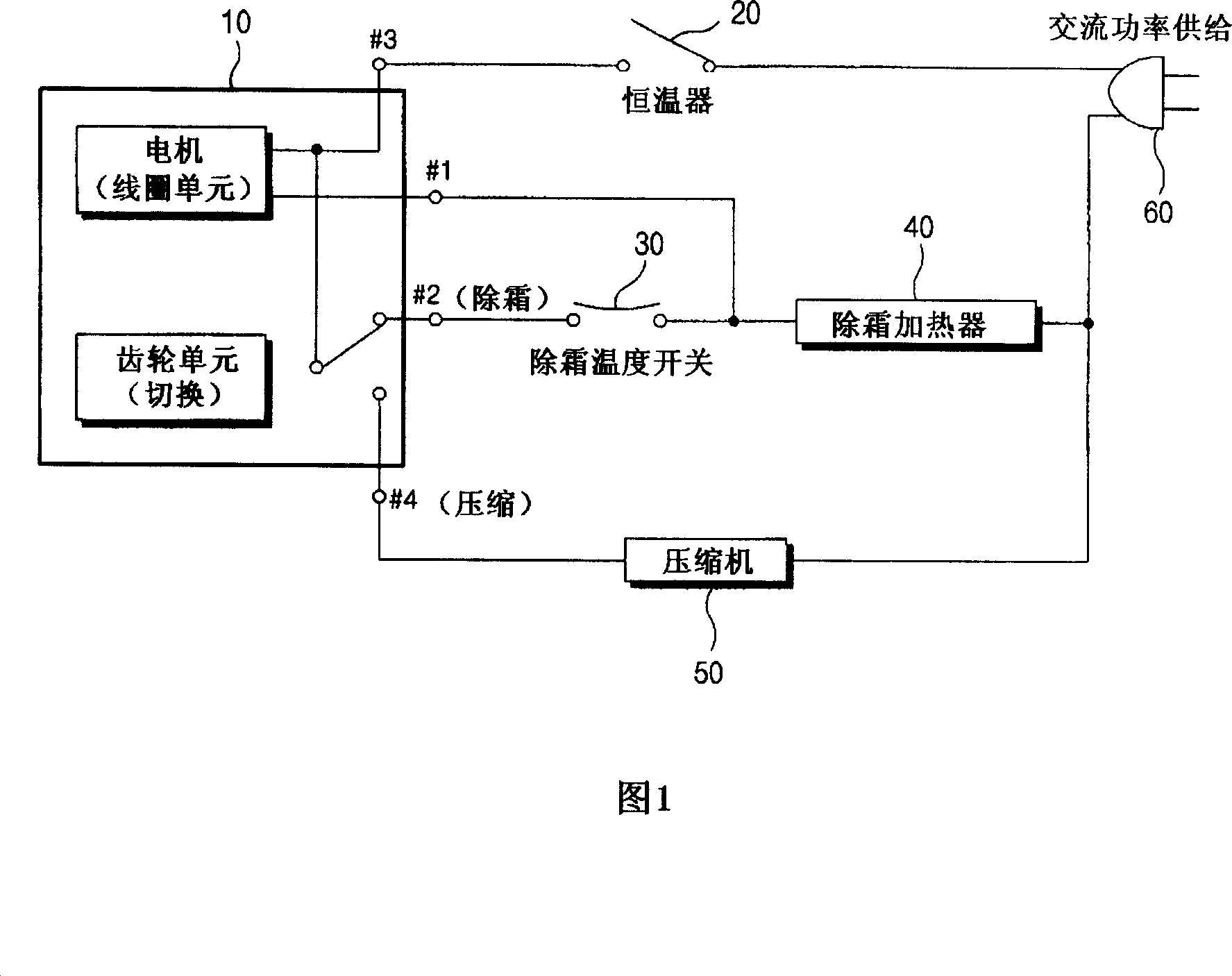

[0023] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. The matters defined in the specification, such as detailed structures and elements, are only specific details provided to help those of ordinary skill in the art fully understand the present invention, and thus the present invention is not limited thereto.

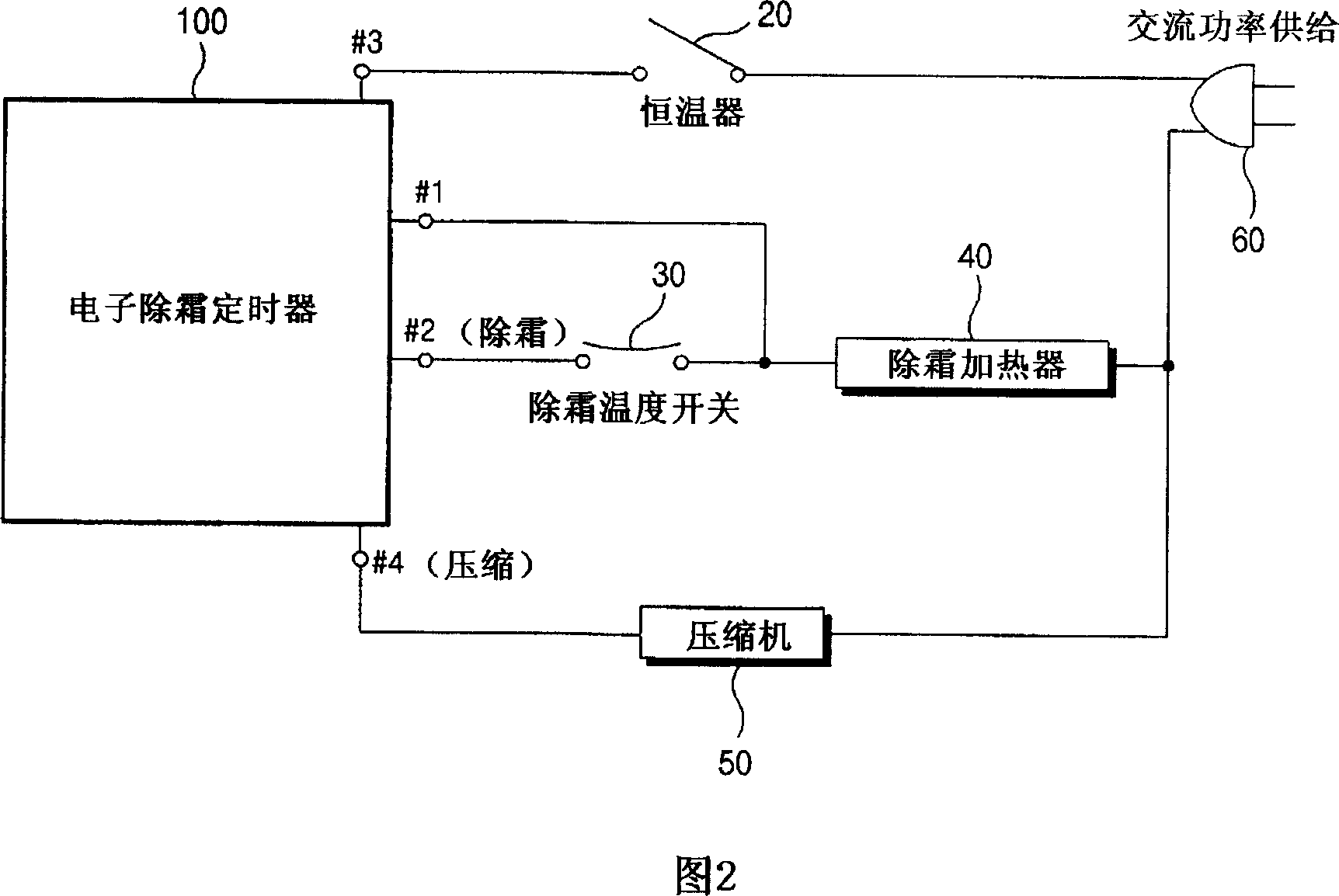

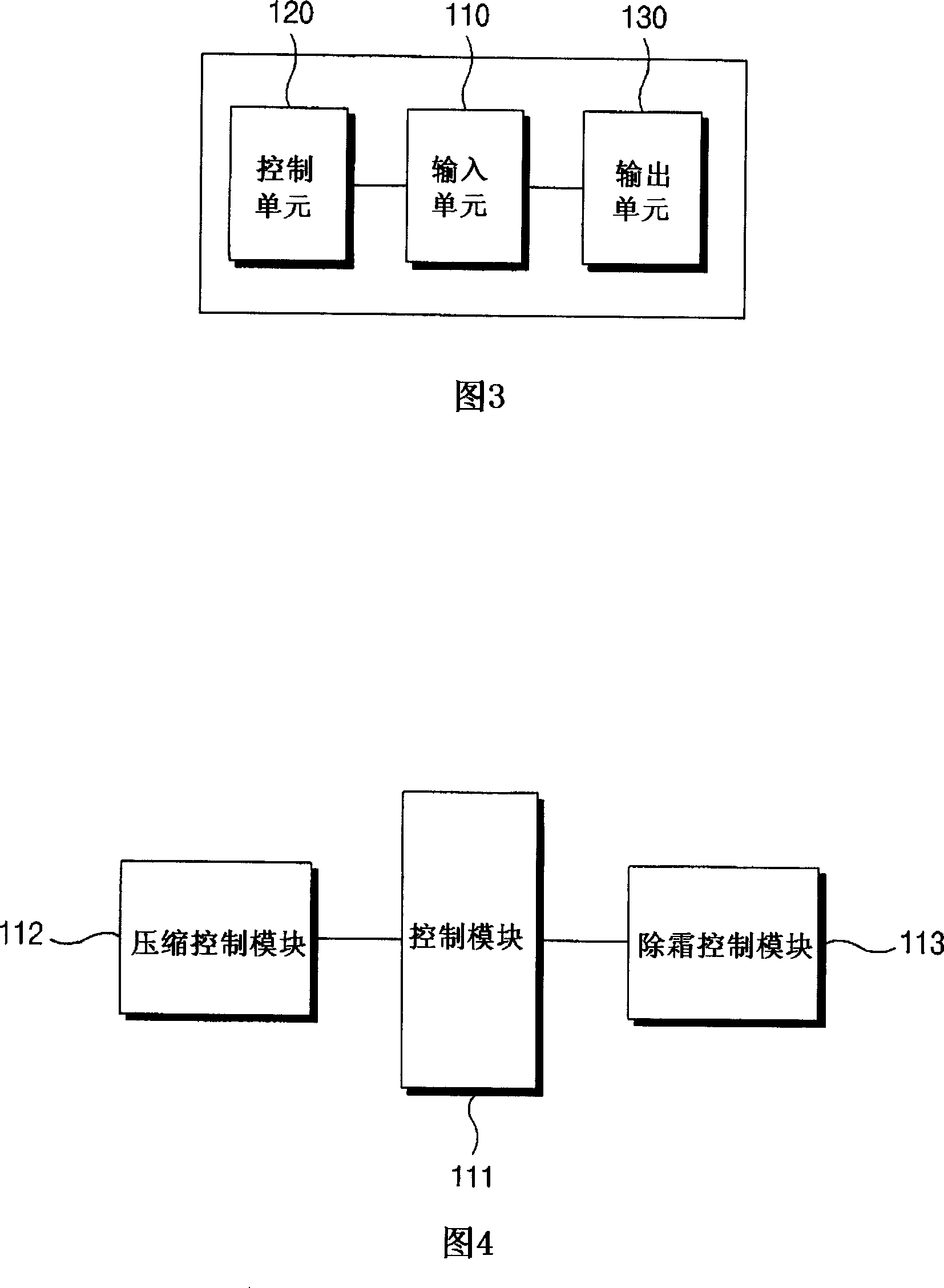

[0024] 2 is a schematic diagram illustrating the overall structure of an electronic defrost timer used in a mechanical refrigerator according to the present invention, and FIG. 3 is a block diagram illustrating the structure of the electronic defrost timer for a mechanical refrigerator according to an embodiment of the present invention.

[0025] Referring to Figures 2 and 3, the structure and operation of an electronic defrost timer for a mechanical refrigerator will now be described in detail.

[0026] As shown in FIG. 2, an electronic defrost timer 100 for a mechanical refrigerator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com