Method for measuring high-pressure buffering pot mud-outlet-flow by open channel method

A high-pressure buffer tank, outlet flow technology, applied in the measurement of flow/mass flow, volume/mass flow generated by mechanical effects, measuring devices, etc., can solve problems such as the inability to quantitatively measure mud flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

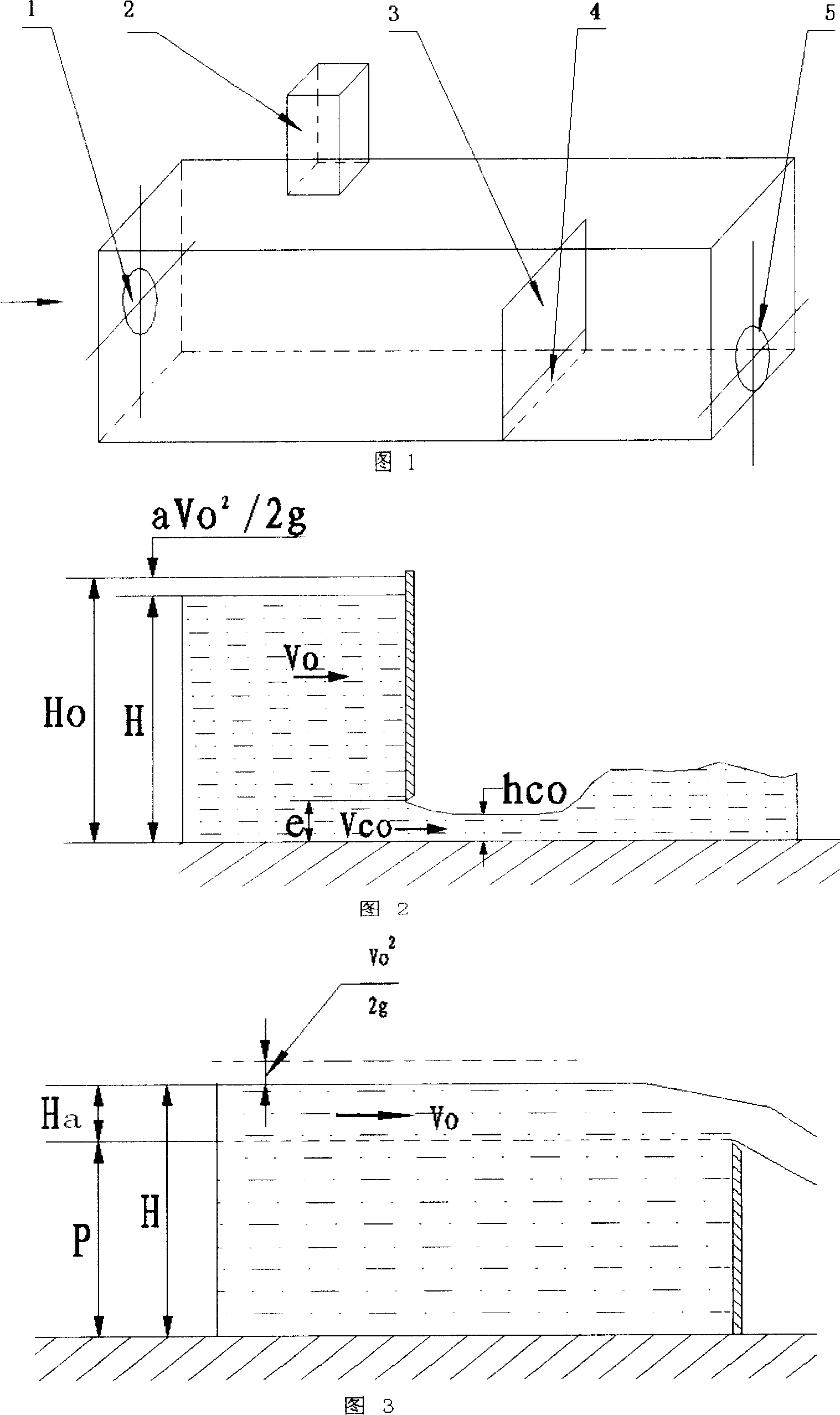

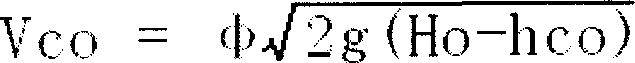

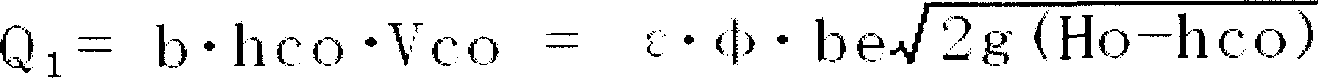

[0009] As shown in Figure 1, Figure 2, and Figure 3, the mud enters the high-pressure buffer tank from (1) and flows out of the buffer tank from (5). After the mud flows in, backwater phenomenon is formed upstream of the baffle plate (3), and when the liquid level remains constant, the gate hole (4) keeps flowing out. In Figure 2: when the gate opening is e, the mud shrinks vertically behind the gate due to its inertia, and forms a minimum shrinkage section somewhere downstream. The height hco of the shrinkage section has the following relationship with the gate opening e:

[0010] hco=εe

[0011] In the formula: ε is the vertical shrinkage coefficient, ε is related to the gate type and relative opening e / H. The flow velocity at the shrinkage section of the gate is:

[0012] V CO = φ 2 g ( Ho - hco ) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com