Molten metal carrying apparatus using ladle

A technology for molten metal and conveying devices, applied in the field of molten metal conveying devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

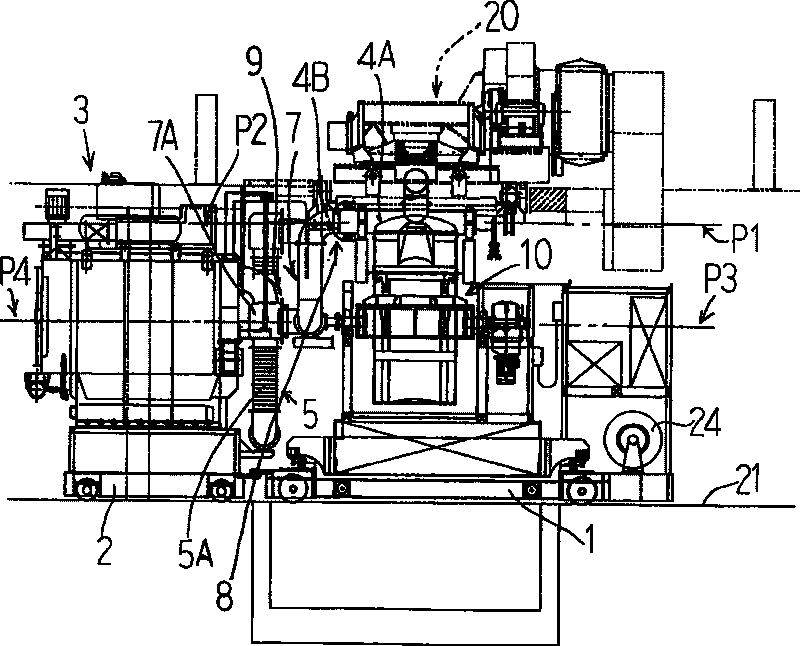

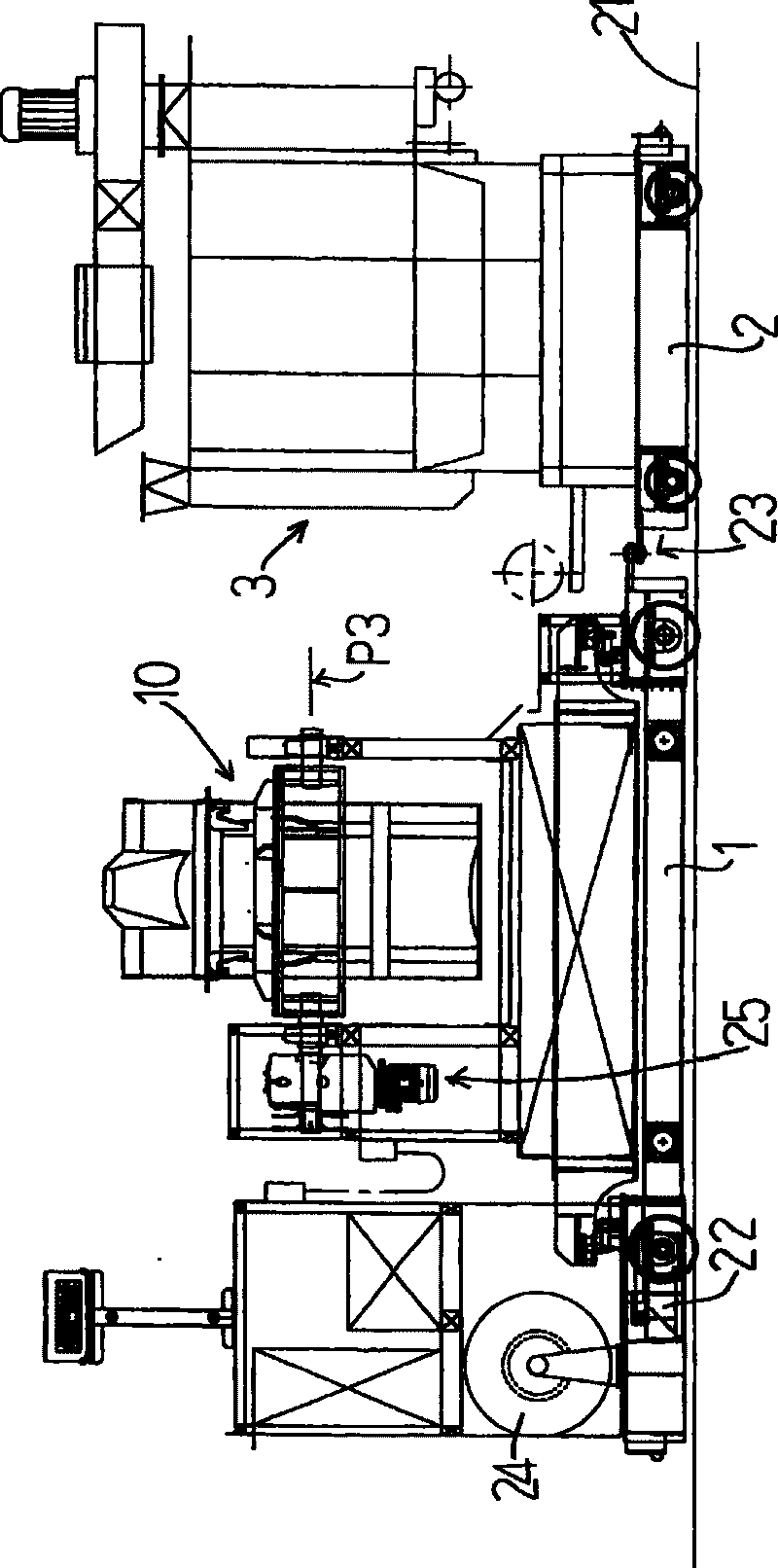

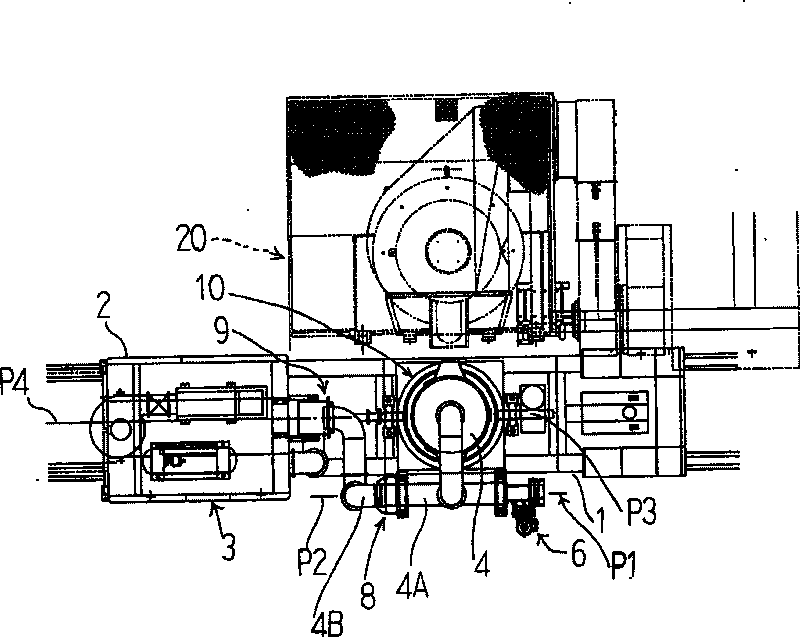

[0057] Below, according to Figure 1 to Figure 7 A preferred embodiment of the molten metal conveying apparatus using a ladle of the present invention will be described in detail. In addition, this invention is not limited to this Example in the range which does not deviate from the gist.

[0058] figure 1 It is a front view of the molten metal conveying device stopped in front of the electric furnace 20, figure 2 is its back view, image 3 is its floor plan, Figure 4 is its side view.

[0059] This molten metal transfer device is configured so that a ladle 10 for receiving molten metal from an electric furnace 20 is mounted on a ladle trolley 1 to be able to move up and down and tilt freely, and is configured to be able to run automatically on a rail 21 laid in a factory. This self-propelled unit is substantially the same as a general electric vehicle, and is provided with a drive motor 22 on the trolley 1 for ladles and is configured to drive wheels. power usage as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com