Hydraulic turbine

A water turbine and hydraulic technology, applied in impact engines, hydroelectric power generation, mechanical equipment, etc., can solve problems such as insufficient power supply, impact on people's production and life, and low utilization rate of water energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

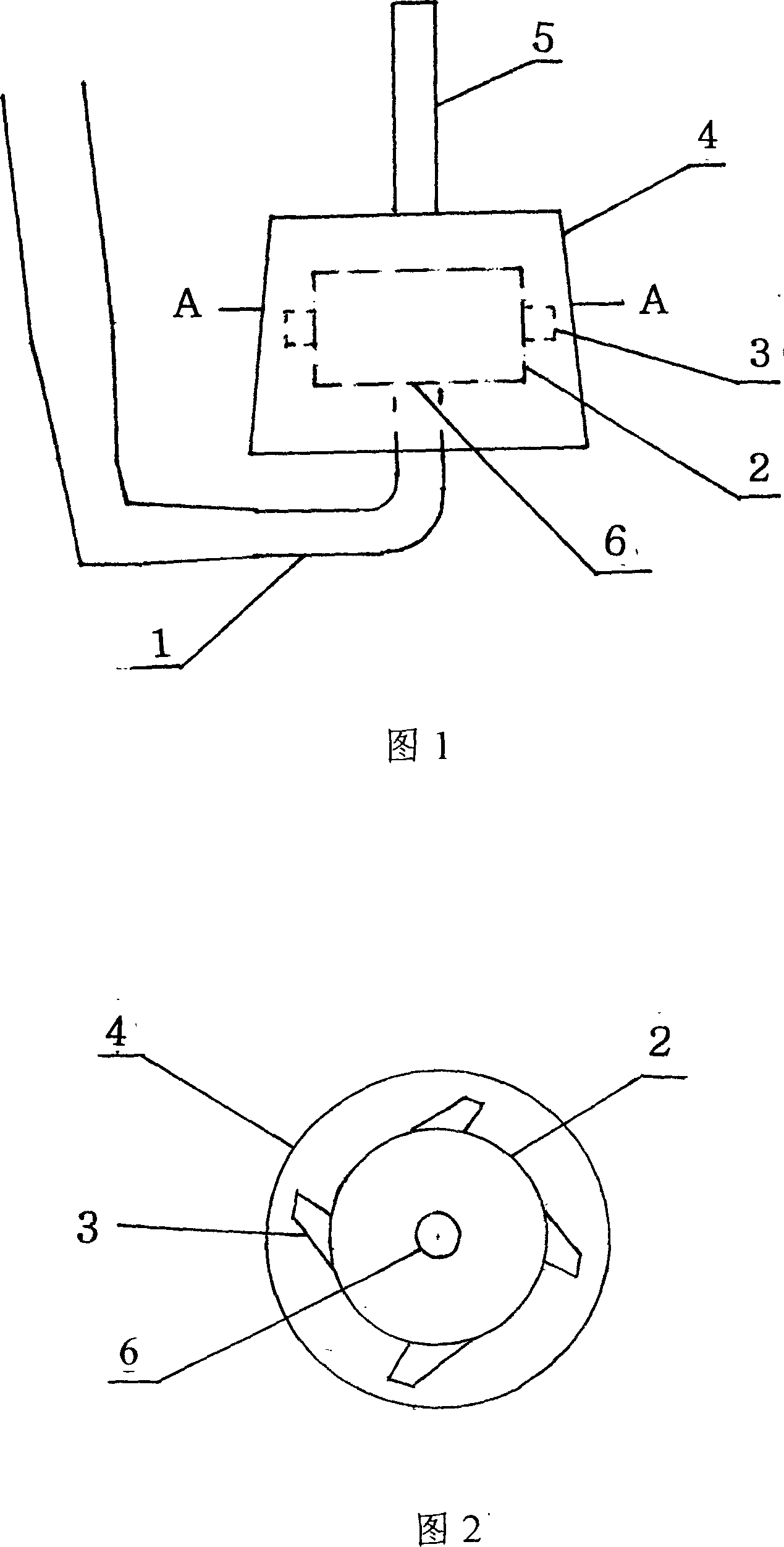

[0007] When the above-mentioned hydraulic water turbine enters the working state, the water flows in from the water inlet pipe (1), flows into the liquid cylinder (2) through the water inlet (6), and is sprayed out from the water spray port (3) to impact the runner (4). Wheel (4) just rotates together with transmission shaft (5), and the current after doing work falls along runner (4) inner wall.

[0008] Features of this machine:

[0009] When the water flow enters the water inlet pipe (1) due to the decreasing cross-section, a very high pressure has been generated when it reaches the water inlet (6), and then enters the hydraulic cylinder (2) to produce the same effect as the principle of the hydraulic machine, and the water flow is greatly increased. pressure, the thrust of water ejected from the water spout (3) increases, and the speed also increases thereupon, and the runner has just obtained extremely high kinetic energy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com