A device and a method for stabilizing a metallic object

A kind of equipment and stable technology, applied in the direction of metal material coating process, hot dip plating process, coating, etc., can solve the problems of large coating thickness, surface defects, uneven coating, etc., to improve efficiency and reduce surface ripple. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

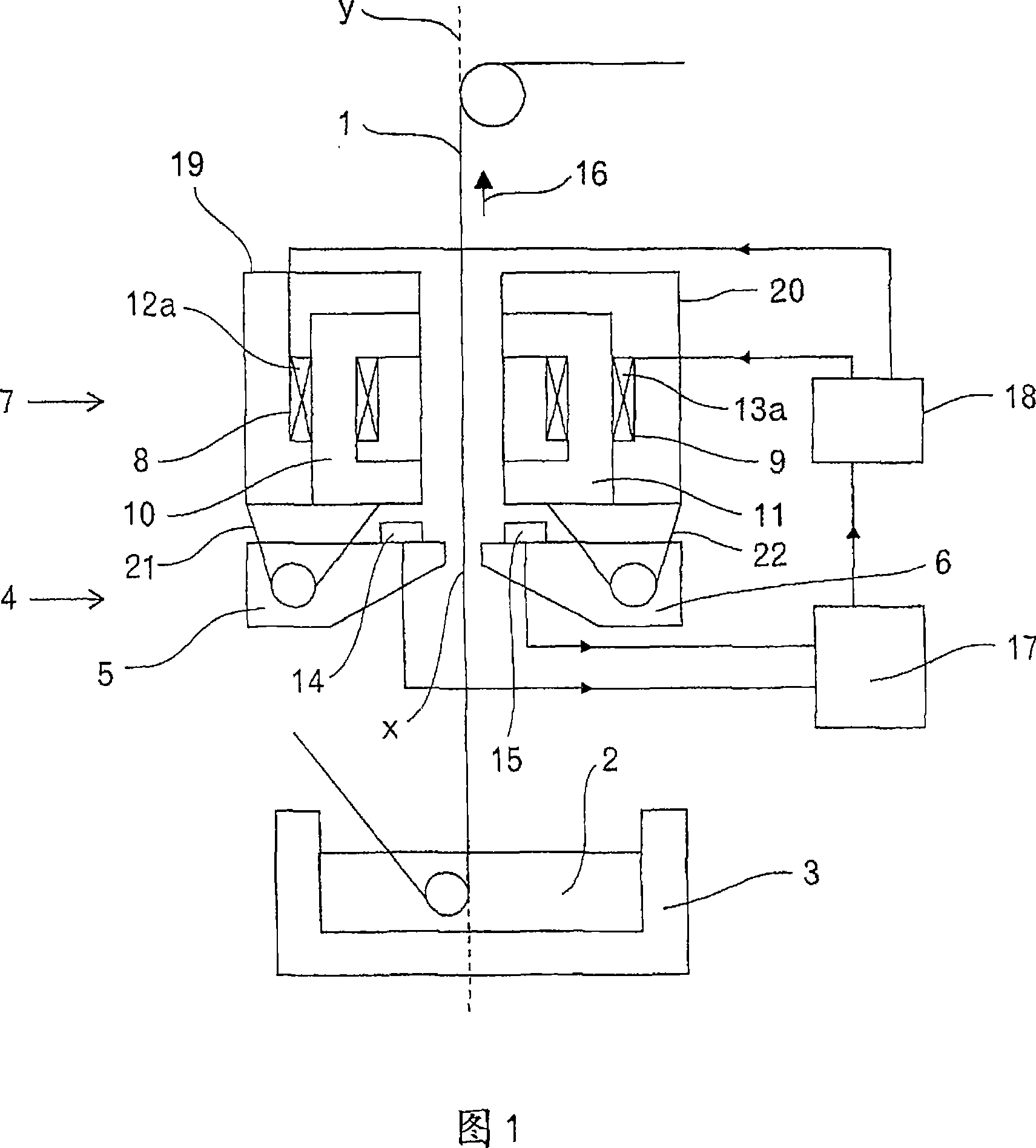

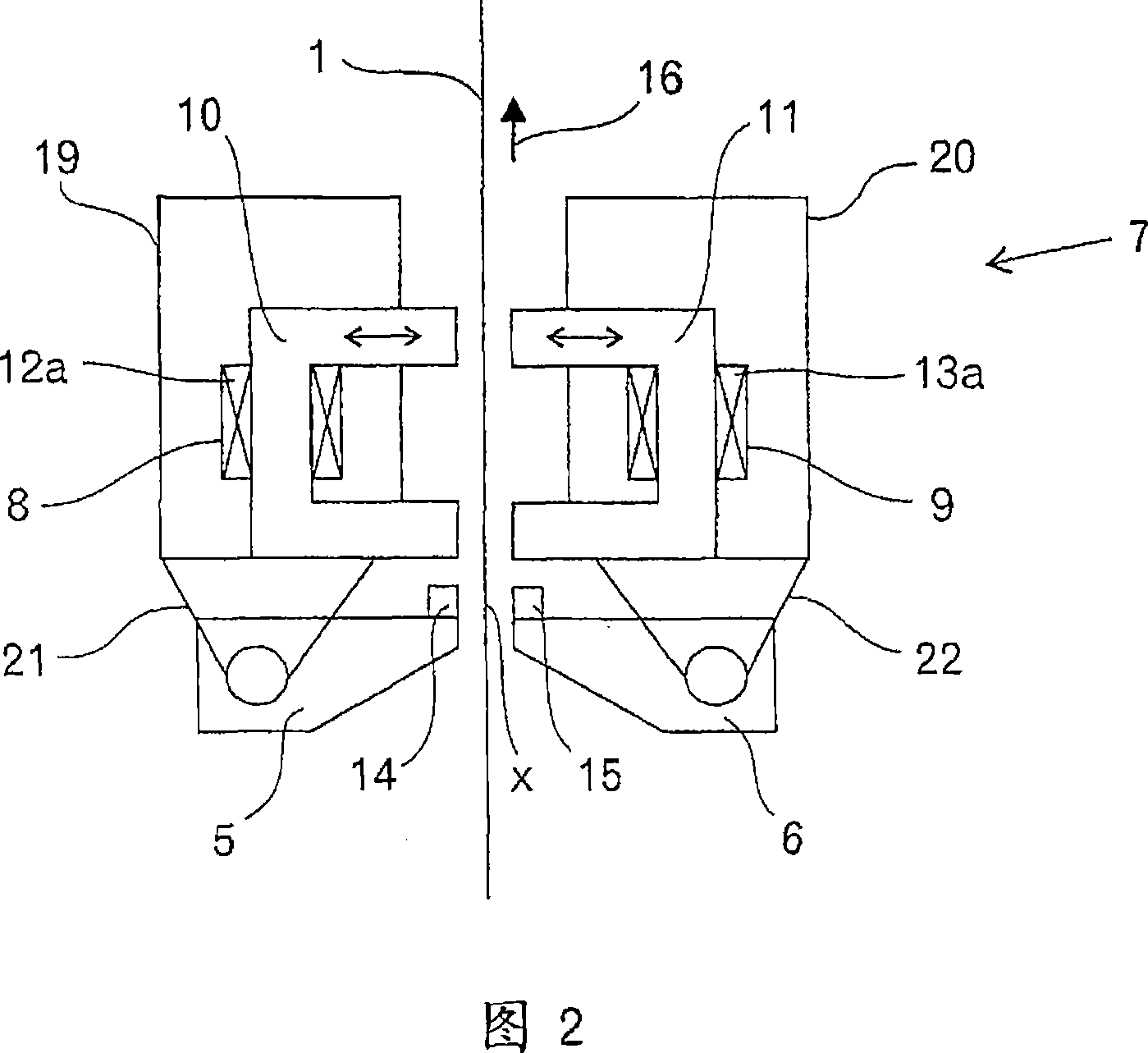

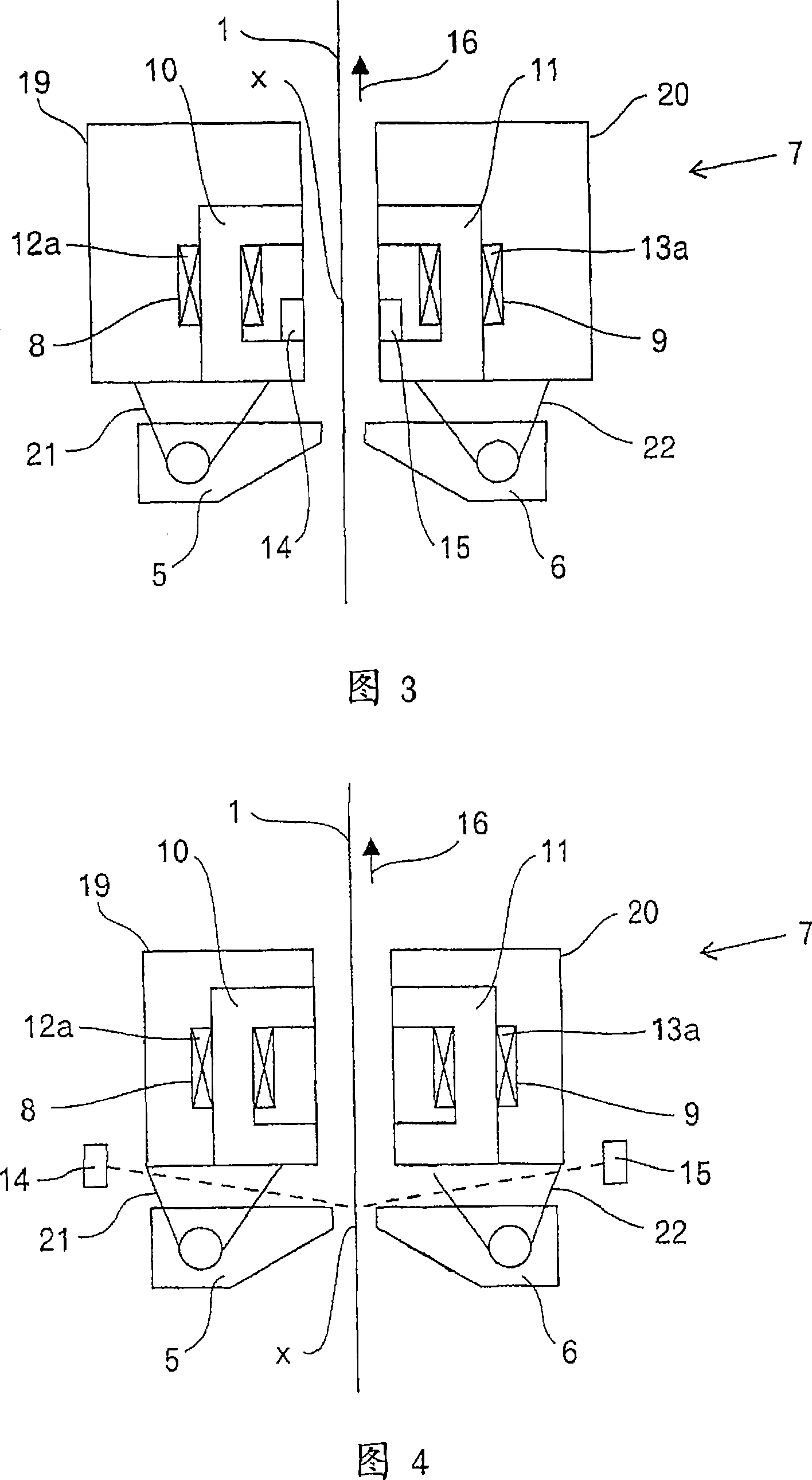

[0035] Figure 1 shows an apparatus for stabilizing an elongated metal strip 1 as it is continuously conveyed through a molten metal plating tank 2 in a vessel 3 to coat the strip.

[0036] The device comprises a wiping device 4 for wiping off excess molten metal from the strip by applying a stream of air to the metal strip, and the wiping device comprises at least a first pair of air knives 5 , 6. The pair of air knives includes one air knife on each side of the strip 1 . The air knives 5, 6 are arranged at the beams 19, 20 by means of suspension devices 21, 22 and since the beams are arranged movable in vertical and horizontal directions, the position of the air knives can be adjusted relative to the position of the strip 1 . The device also comprises an electromagnetic stabilizing device 7 arranged to stabilize the position of the strip relative to the predetermined transport path x. The electromagnetic stabilizing device 7 comprises at least one first pair of electromagne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com