High young's modulus steel plate, zinc hot dip galvanized steel sheet using the same, alloyed zinc hot dip galvanized steel sheet, high young's modulus steel pipe, and method for production thereof

A technology of hot-dip galvanized steel sheet and Young's modulus, which can be used in manufacturing tools, heat treatment furnaces, heat treatment equipment, etc., and can solve problems such as inability to obtain shapes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

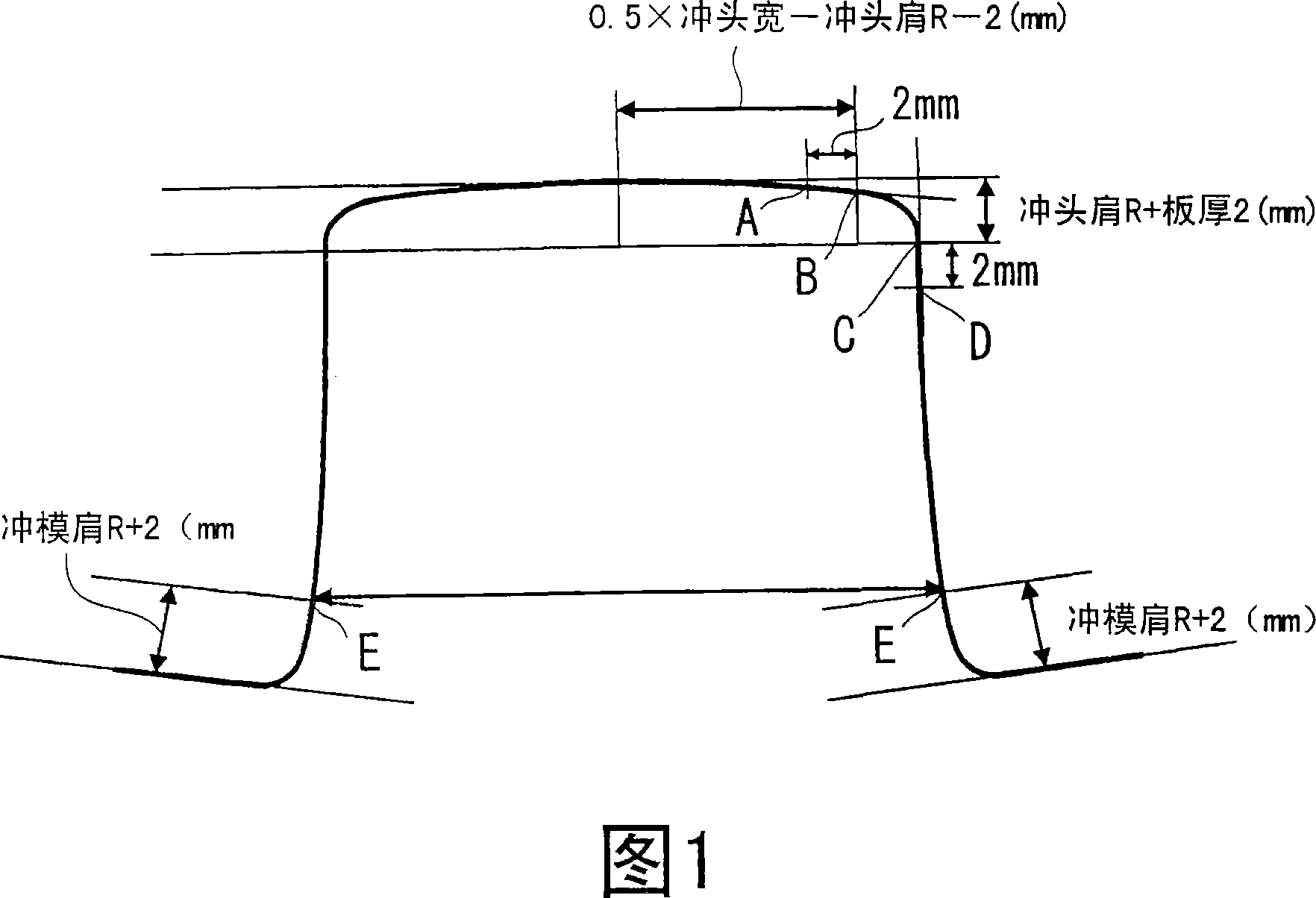

Image

Examples

no. 1 Embodiment approach

[0083] The steel sheet according to the first embodiment contains C: 0.0005% to 0.30%, Si: 2.5% or less, Mn: 2.7 to 5.0%, P: 0.15% or less, S: 0.015% or less, Mo: 0.15% to 1.5% by mass %. %, B: 0.0006 to 0.01%, Al: 0.15% or less; and the balance is composed of Fe and unavoidable impurities. The pole density of either or both of {110} and {110} in the 1 / 8 layer of plate thickness is 10 or more, and the Young's modulus in the rolling direction exceeds 230GPa.

[0084] C is an inexpensive element that increases tensile strength, and its addition amount is adjusted according to the target strength level. When C is less than 0.0005% by mass, not only the steelmaking is technically difficult, but also the cost increases, and the fatigue properties of the weld zone deteriorate. Therefore, the lower limit was determined to be 0.0005% by mass. On the other hand, when the C content exceeds 0.30% by mass, it causes deterioration of formability or impairs weldability. Therefore, the up...

no. 2 Embodiment approach

[0145] The steel sheet of the second embodiment contains C: 0.0005% to 0.30%, Si: 2.5% or less, Mn: 0.1 to 5.0%, P: 0.15% or less, S: 0.015% or less, Al: 0.15% or less in mass % , N: 0.01% or less; and one of Mo: 0.005 to 1.5%, Nb: 0.005 to 0.20%, Ti: 48 / 14×N (mass%) to 0.2%, and B: 0.0001 to 0.01% or Two or more kinds, the total is 0.015 to 1.91% by mass; and the balance is composed of Fe and unavoidable impurities. The pole density of {110} and / or {110} in the 1 / 8th layer of the plate thickness is 10 or more, and the Young's modulus in the rolling direction exceeds 230 GPa.

[0146] Here, the reasons for limiting the steel composition as described above will be described.

[0147] C is an element that increases the tensile strength inexpensively, and its addition amount is adjusted according to the target strength level. When C is less than 0.0005% by mass, not only steelmaking is technically difficult and the cost increases, but also the fatigue properties of the wel...

no. 3 Embodiment approach

[0217] In the third embodiment, a hot-dip galvanized steel sheet having a high Young's modulus, an alloyed hot-dip galvanized steel sheet, a high Young's modulus steel pipe, and a method for producing the same in the first and second embodiments described above An example of .

[0218] The hot-dip galvanized steel sheet includes the high Young's modulus steel sheet of the first and second embodiments, and the hot-dip galvanizing performed on the high Young's modulus steel sheet. The hot-dip galvanized steel sheet is produced by hot-dip galvanizing the annealed hot-rolled steel sheet or the cold-rolled cold-rolled steel sheet obtained in the first and second embodiments described above.

[0219] The composition of the galvanized layer is not particularly limited, and in addition to zinc, Fe, Al, Mn, Cr, Mg, Pb, Sn, Ni, etc. may be added as needed.

[0220] Heat treatment and galvanizing on a continuous hot-dip galvanizing line after cold rolling are also acceptable.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com